The global pet food market is projected to reach $133 billion by 2030, and producers that invest in superior food processing machines today will be the brands consumers trust tomorrow. This guide walks you through every step—from equipment selection to future-proofing your line—so you can scale confidently and profitably.

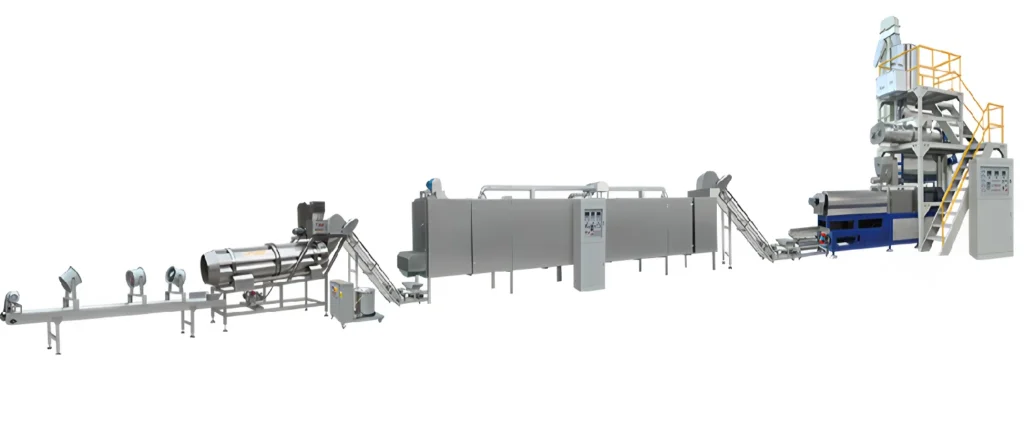

A Quick Look at the Modern Production Flow

If you’re new to pet food manufacturing, here’s the five-step backbone of nearly every factory:

- Ingredient Preparation – grinding, mixing, and hygienic weighing.

- Forming – shaping kibbles, treats, or wet portions.

- Cooking / Extrusion – heat & pressure for safety and digestibility.

- Drying / Cooling – achieving target moisture for shelf life.

- Packaging – sealing and coding for traceability.

Equipment Deep-Dive & Technical Benchmarks

Core Machines You’ll Compare — At a Glance

| Equipment | Typical Output (kg/h) | Key Metric | Our Model Advantage |

|---|---|---|---|

| Pre‑conditioner Mixer | 300 – 5,000 | ±1% recipe accuracy | Dual‑shaft, CIP ready |

| Single‑screw Extruder | 500 – 7,000 | 15% energy saving | Patented barrel cooling |

| Twin‑screw Extruder | 100 – 5,000 | Moisture up to 35% | Quick‑swap screw elements |

| Multi‑layer Dryer | 200 – 10,000 | <10 min change‑over | Gas or electric hybrid |

| Vacuum Coater | 150 – 6,000 | Coating uniformity >97% | Low‑fat pickup design |

Twin-Screw vs. Single-Screw — Which Fits Your Recipe?

Twin-screw technology boasts superior mixing, ventilation, and high-moisture capability—ideal for grain-free or fresh-meat formulas. Single-screw lines remain cost-efficient for classic dry kibble. Ask yourself:

- Need > 25 % fresh meat? Twin-screw wins.

- Budget the driving factor? Start single-screw.

- Expanding SKUs soon? Twin-screw offers modularity.

Real-World Case Study: Tripling Output in Germany

Client / Location: Mid-size private-label dog food producer, Hamburg

Challenge: 100 kg/h single-screw line could not meet retailer demand; downtime averaged 14 % per month.

Solution: Installed a 300 kg/h food extruder, multi-layer dryer, and CIP system.

Results (6 months):

- Output ↑ 210 % (100 → 310 kg/h)

- Downtime ↓ 3.8 %

- Energy per kg ↓ 12 %

- Staff reduced 5 → 3 operators

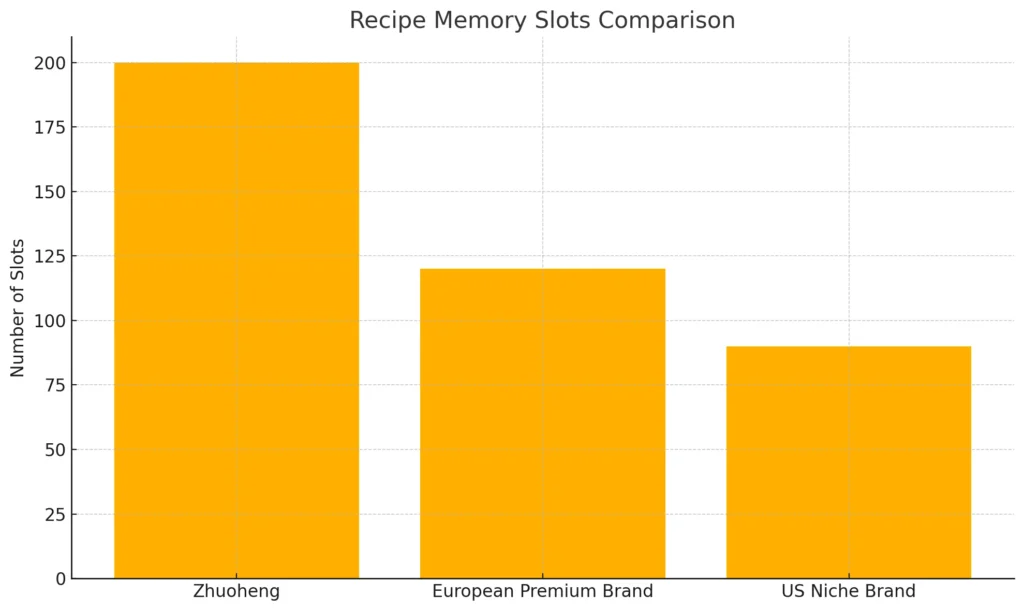

How We Stack Up Against Global Brands

| Feature | Zhuoheng | European Premium Brand | US Niche Brand |

|---|---|---|---|

| Lead Time | 10–12 weeks | 18–24 weeks | 14–16 weeks |

| On‑site Commissioning | Included | Optional, costly | Minimal |

| Recipe Memory Slots | 200+ | 120 | 90 |

| Energy Efficiency | ★ ★★ ★ | ★ ★★ ★ | ★ ★ |

| Total Cost of Ownership (5 yrs) | Lowest | Highest | Medium |

Challenges & Future Outlook

Market Pressures

- Consumer Transparency: Shoppers want to trace every ingredient’s origin.

- Sustainability: Expect inquiries on carbon footprint and recyclable packaging.

- Logistics Bottlenecks: Port congestion and driver shortages inflate costs.

How the Right Machine Solves Them

Integrating MES modules lets our line export batch data to your ERP—ready for retailer audits. Energy-smart dryers cut CO₂ / ton by 18 %. Modular pack stations accept compostable films with minor tooling swaps..

Action Checklist Before You Invest

- Confirm target capacity plus 30 % headroom.

- Request CE & ISO certificates in the quotation.

- Ask for an energy-usage sheet at three load levels.

- Budget for spare parts (≈3 % of Cap-Ex annually).

- Book a Factory Acceptance Test (FAT) before shipment.

Frequently Asked Questions (FAQ)

What machine is best for high-meat, grain-free kibble?

A twin-screw food extruder handles up to 35 % fresh meat while maintaining expansion and density control.

How long is the average installation period?

For a 300 kg/h line: 5 days mechanical, 3 days electrical, and 2 days trial runs—under normal site readiness.

Do your lines comply with FEDIAF guidelines?

Yes. Our hygienic design follows FEDIAF Good Manufacturing Practice for pet food.

Can I switch from dog treats to cat kibble on the same extruder?

Absolutely. Change-over takes ~20 minutes by swapping die plates and recipe parameters.

What is the typical lead time?

10 – 12 weeks ex-works for standard configurations; custom modules may extend by 2 weeks.