In the modern aquaculture industry, producing high-quality fish feed is crucial for improving fish growth, health, and overall farm productivity. Many small and medium aquaculture businesses face challenges like inconsistent feed quality, nutrient loss, and high production costs. Understanding the entire production process—from raw material selection to finished pellet packaging—not only ensures superior feed performance but also maximizes profitability.

Step 1: Raw Material Selection and Preparation

The foundation of quality fish feed lies in the selection of raw ingredients. Typical materials include fish meal, soybean meal, corn gluten, wheat, rice bran, and essential oils. Depending on the target species—carnivorous, omnivorous, or herbivorous—the nutritional composition must be carefully formulated. For example:

Ingredients, Function, and Typical Inclusion Percentages

| Ingredient | Function | Typical Inclusion % |

|---|---|---|

| Fish meal | Protein source, growth promoter | 20–40% |

| Soybean meal | Plant protein, amino acids | 15–25% |

| Corn gluten | Energy, binding | 10–20% |

| Wheat | Starch, pellet binder | 5–15% |

| Rice bran | Fat, fiber | 5–10% |

| Fish oil | Omega-3, attractant | 1–5% |

| Vitamin & mineral premix | Health, immunity | 0.5–2% |

Raw materials should be clean, dry, and ground to a uniform fineness (0.5–0.8 mm) using a hammer mill or grinder to improve digestibility and pellet formation. Advanced grinding ensures consistent particle size, improving feed homogeneity and binding properties during extrusion.

Step 2: Mixing and Homogenization

Accurate mixing is critical to ensure each pellet contains the correct proportion of nutrients. A ribbon blender or paddle mixer is typically used for uniform distribution of powdered ingredients. Liquids like fish oil or vitamin premixes are added towards the end and thoroughly homogenized. The target moisture content after mixing is around 12–14%.

For industrial-scale operations, automated weighing and dosing systems can drastically improve accuracy, reduce human error, and optimize production efficiency.

Step 3: Conditioning and Pre-Processing

Conditioning is an optional but highly recommended step, especially when using a Fish Food Extruder. In a steam preconditioner, the feed mixture is exposed to controlled heat and moisture, initiating starch gelatinization and improving pellet binding. This step also reduces microbial contamination and enhances digestibility.

Typical Conditioning Parameters

| Parameter | Value | Purpose |

|---|---|---|

| Temperature | 70–90 °C | Partial starch gelatinization |

| Moisture | 12–15% | Improve pellet binding |

| Retention time | 2–5 minutes | Even heat and moisture distribution |

Step 4: Extrusion or Pelletizing

The extrusion step is the heart of the production process. The conditioned mixture is fed into a single or twin-screw extruder, where high pressure, temperature (120–150 °C), and mechanical shear transform the feed into pellets. Key parameters include:

Pellet size: 0.9–12 mm, depending on fish species

Feed type: floating, sinking, or slow-sinking

Shape and density: customizable for specific aquaculture requirements

Cooking degree: ensures digestibility and nutrient availability

Floating pellets are particularly advantageous in modern fish farming because they allow farmers to monitor feeding, reduce waste, and improve water quality. Twin-screw extruders offer precise control over shape, size, and nutrient retention, ensuring consistent high-quality pellets.

Step 5: Drying

Freshly extruded pellets have high moisture content (~22–28%) and must be dried to ≤10% to prevent mold growth and extend shelf life. Continuous belt dryers with controlled airflow and temperature zones are recommended. Proper drying ensures physical stability and prevents nutrient leaching.

Step 6: Coating and Flavoring

Once dried, pellets can be coated with fish oil, vitamins, or attractants using a vacuum coating machine. This improves palatability, energy content, and feed conversion ratio (FCR), which is a critical metric for aquaculture profitability.

Step 7: Cooling and Sieving

Cooling stabilizes the pellets and prevents condensation inside packaging. Sieving removes broken pellets and dust, ensuring only premium quality feed reaches storage or sale. A counterflow cooler is ideal for maintaining consistent temperature (~30 °C) and pellet integrity.

Step 8: Packaging and Storage

Proper packaging is essential to maintain feed quality. Pellets are typically packed in PP/PE laminated bags or multi-layer vacuum pouches. Storage should be in a dry, ventilated warehouse with <30 °C temperature and <70% humidity.

Nutritional Optimization and Species-Specific Feed

Different fish species have unique dietary needs. For instance:

Species-Specific Feed Formulation

| Species | Protein % | Fat % | Pellet Type |

|---|---|---|---|

| Tilapia | 28–32% | 5–8% | Floating |

| Catfish | 30–35% | 6–10% | Sinking |

| Salmon | 40–45% | 15–20% | Floating |

| Carp | 25–30% | 4–6% | Slow-sinking |

Optimizing nutrient composition ensures growth, immunity, and feed efficiency. Advanced Fish Food Processing Machines allow precise control of protein, fat, carbohydrate, vitamin, and mineral levels for each batch.

Practical Tips for Quality Control

Check pellet buoyancy: floating pellets should remain afloat >12 hours

Monitor expansion ratio: adjust extruder temperature, moisture, and screw speed

Test durability: <5% fines after cooling

Regularly calibrate feeders, mixers, and dosing systems

Perform proximate analysis for protein, fat, fiber, and ash

Maintain hygienic production to prevent bacterial contamination

Common Problems and Solutions

Problem, Cause, and Solution

| Problem | Cause | Solution |

|---|---|---|

| Pellets float poorly | Excess moisture, low starch gelatinization | Adjust conditioning temperature & moisture |

| Pellet breakage | Inadequate extrusion pressure | Increase extruder pressure or optimize die |

| Low nutrient retention | Overheating during extrusion | Reduce temperature or adjust screw speed |

| Mold growth | Improper drying or storage | Ensure drying to ≤10% moisture & proper storage |

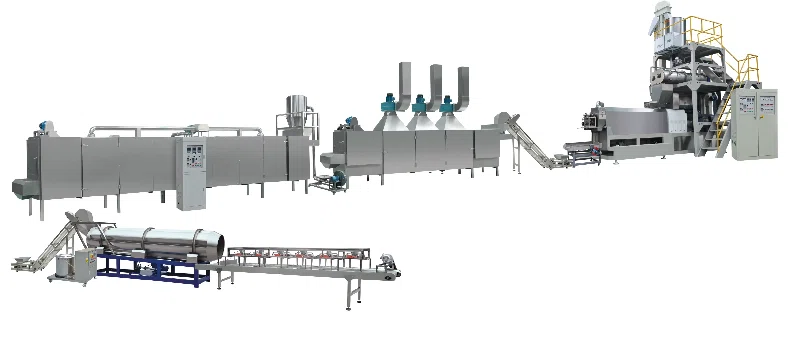

Custom Solutions with Our Equipment

Our turnkey Fish Feed Production Line allows clients to customize pellet size, type, and output. From raw material grinding to automatic packaging, our solutions cater to small farms, medium businesses, and large-scale commercial operations worldwide. Using our twin-screw extruders, you can achieve optimal floating pellet quality, high nutrient retention, and improved feed conversion ratios.

FAQs

-

Q: What are the main steps in fish feed production?

A: The main steps include raw material selection, grinding, mixing, conditioning, extrusion or pelletizing, drying, coating, cooling, sieving, and packaging. Each step ensures feed quality and species-specific nutrition.

-

Q: How does extrusion improve feed quality?

A: Extrusion gelatinizes starch, denatures proteins, and improves pellet structure, digestibility, and water stability, resulting in better feed utilization and growth performance.

-

Q: What is the role of coating in fish feed production?

A: Coating with oils, vitamins, or attractants enhances palatability, energy content, and feed conversion ratio, reducing feed waste and improving growth.

-

Q: How can I choose the right pellet mill?

A: Consider capacity, pellet size, shape, durability, energy efficiency, and ease of maintenance. Twin-screw extruders are ideal for floating feed, while single-screw models are suitable for sinking feed and small-scale production.

-

Q: How should fish feed be stored?

A: Store in dry, ventilated warehouses at <30 °C and <70% humidity. Use moisture-proof packaging to preserve nutrients and prevent mold.