Introduction: Why Modern Feed Processing Matters

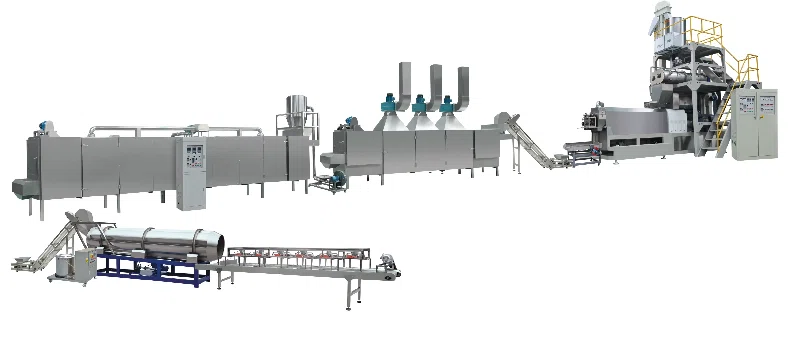

In the modern aquaculture industry, efficiency, feed quality, and production consistency are the keys to profitability. Traditional manual or semi-automatic production methods often lead to uneven feed sizes, nutrient loss, or contamination during mixing and drying. A well-designed Fish Feed Production Line provides a reliable solution to these problems. It integrates multiple machines—from crushing to packaging—into a fully automated and efficient system that can handle everything from raw ingredients to finished pellets.

What Is a Fish Feed Production Line?

A Fish Feed Production Line is a complete system designed to process raw ingredients like fish meal, soybean meal, corn, and vitamins into nutritious feed pellets. In my experience, each production line can be tailored based on capacity (from 100 kg/h to 5 tons/h), pellet type (floating, slow-sinking, or sinking), and automation level.

If you’re planning to establish or expand your feed plant, you can explore our specialized solutions for Fish Feed Production Line, which include layout design, process optimization, and installation support.

Key Equipment in a Complete Production Line

A professional feed line typically includes the following essential machines:

| Equipment | Function | Key Features |

|---|---|---|

| Crusher | Grinds raw materials into fine powder | Adjustable mesh size for flexible grinding |

| Mixer | Ensures uniform ingredient blending | Optional liquid dosing system |

| Fish Food Extruder | Shapes and cooks feed under heat and pressure | Floating/sinking control via screw & temperature |

| Dryer | Removes moisture from hot pellets | Multi-layer stainless steel conveyor |

| Cooler | Cools and hardens pellets | Energy-efficient counterflow design |

| Oil Coater | Adds oil and vitamins | Vacuum coating for better absorption |

| Screener | Separates dust and broken pellets | Ensures uniform particle size |

| Packing Machine | Weighs and bags finished pellets | PLC automated system |

Production Flow Explained

The feed production process follows a strict step-by-step sequence:

Raw Material Grinding → Mixing → Extrusion → Drying → Cooling → Coating → Screening → Packaging

In each stage, precise temperature, moisture, and timing are controlled by PLC systems. This ensures feed stability and consistent nutritional content.

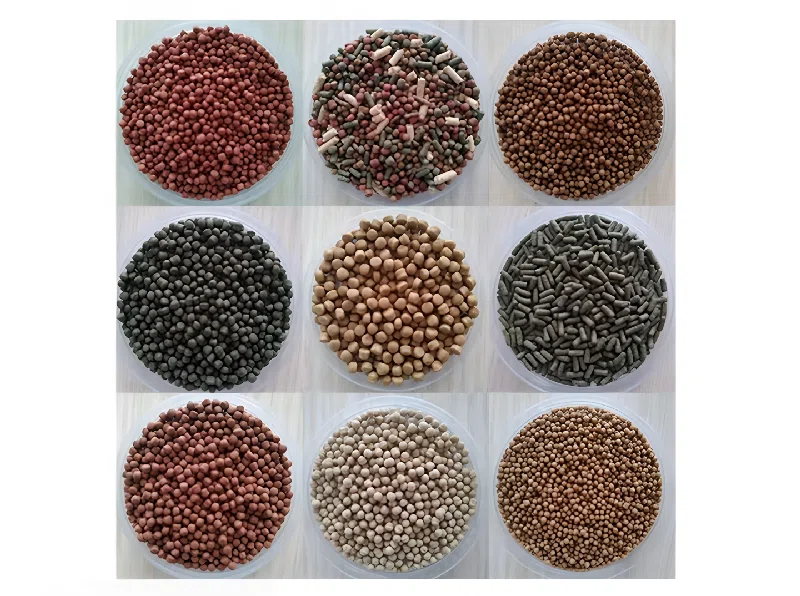

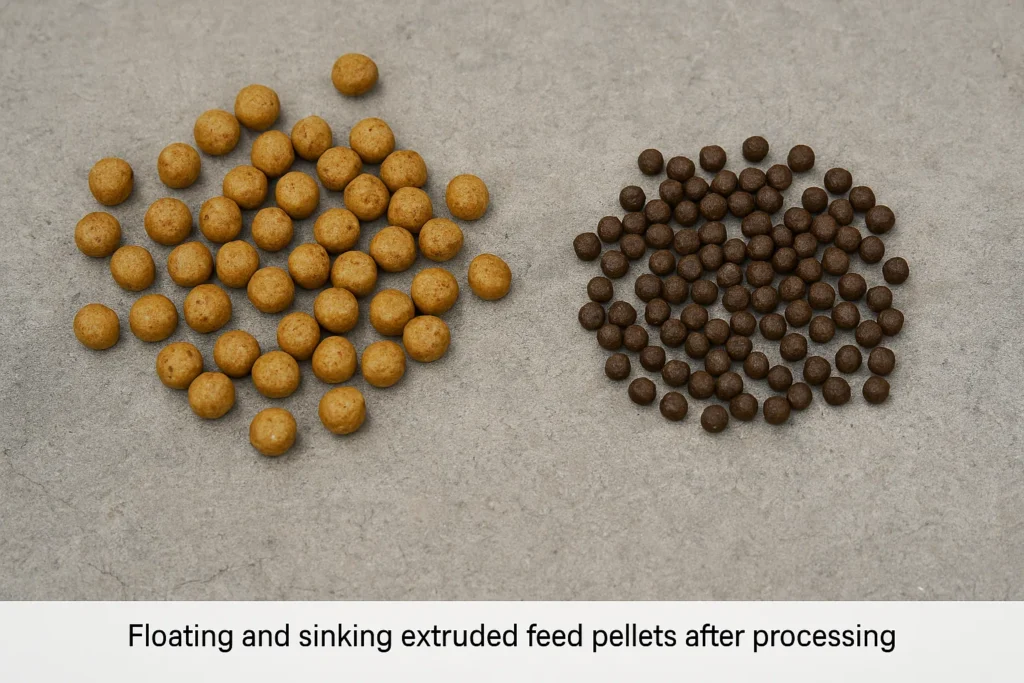

Floating vs. Sinking Feed: Choosing the Right Type

The extrusion process allows you to control pellet buoyancy through temperature, pressure, and screw configuration adjustments.

Floating Feed: Ideal for surface fish like tilapia and catfish.

Sinking Feed: Suitable for shrimp or bottom feeders.

Slow-Sinking Feed: Balanced type for mixed species farming.

Customized Feed Plant Solutions for Every Business

In my years of working with feed processors, I’ve learned that no two production needs are identical. That’s why our engineering team provides custom-designed Fish Food Processing Machine systems for every client. Whether you’re upgrading an existing facility or starting a new line, we design the layout, recommend the ideal extruder size, and ensure the full system runs efficiently from day one.

Benefits of a Fully Automated Line

✅ Consistent pellet size and quality

✅ Reduced labor and energy costs

✅ Precise control over moisture and density

✅ Long service life with easy maintenance

✅ Improved feed conversion ratio for aquaculture farms

Case Study: Energy-Efficient Production in Southeast Asia

One of our clients in Thailand upgraded from a traditional pellet mill to our Food Fish Processing Equipment system. Their output increased from 800 kg/h to 2 tons/h while cutting power consumption by 20%. They also achieved uniform floating feed quality that improved fish growth by 15%.

After-Sales and Technical Support

Our support doesn’t end after installation. We provide full technical assistance, operator training, spare parts supply, and remote troubleshooting. This ensures your feed line continues to operate with maximum efficiency for years.

Final Thoughts

A well-built Fish Feed Production Line not only boosts efficiency but also builds your long-term competitive edge in aquaculture feed manufacturing. With the right system and professional guidance, you can produce premium-quality feed that meets export standards while reducing production cost.

If you’re planning to expand your aquafeed business, our Fish Food Extruder and custom solutions can help you design the ideal setup for your market needs.

Q&A: Common Questions About Fish Feed Production

Can one line produce both floating and sinking feed?

Yes. By adjusting extrusion pressure and moisture, one line can flexibly switch between floating and sinking feed production.

What is the installation time for a complete feed plant?

Typically, 25–40 days depending on scale and customization level.

Do you offer on-site training for operators?

Yes. We provide full operator training and remote assistance to ensure smooth operation.

What is the minimum capacity available?

The smallest line starts from 100 kg/h, ideal for pilot or small-scale production.

✅ Ready to upgrade your fish feed plant? Contact us today to discuss your ideal production solution.