In modern aquaculture, selecting the right feed production equipment is crucial for efficiency and fish health. Two common technologies are the Fish Feed Extruder and the Pellet Mill. While both produce pelleted feed, their processes, product characteristics, and applications differ significantly. Understanding these differences helps feed manufacturers and aquaculture businesses optimize feed quality, reduce costs, and improve fish growth.

Basic Working Principles

Fish Feed Extruder uses high-pressure and high-temperature processing, often with steam injection, to gelatinize starches and denature proteins. This creates highly digestible, porous, and often buoyant pellets. The process allows for higher fat content and eliminates the need for binders in most formulations.

On the other hand, a Pellet Mill employs mechanical compression to form dense pellets from powdered raw materials. The process usually requires pellet binders and is limited to lower fat content formulas. Pellet mills produce mostly sinking pellets with less processing of nutrients.

Key Differences at a Glance

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| Feature | Fish Feed Extruder | Pellet Mill |

|---|---|---|

| Processing Method | High-pressure, high-temperature extrusion with steam | Mechanical compression of raw material through dies |

| Pellet Density | Less dense, porous, controllable floating or sinking | Dense and smooth, mostly sinking |

| Buoyancy | Floating feed possible by controlling starch gelatinization | Generally sinking feed |

| Key Ingredients | Handles higher fat/oil levels; minimal binders needed | Requires lower fat; binders needed |

| Digestibility | Improved due to cooking effect; proteins and starch gelatinized | Less digestible due to lower processing temperature |

| Application | Floating feed for trout, salmon, sea bass; high-fat formulas | Sinking feed for shrimp, carp, cod; low-fat formulas |

| Equipment Cost | Higher initial investment; lower feed conversion in large scale | Lower initial cost; suitable for small to medium scale |

Feed Quality Comparison: Floating vs Sinking Feed

The primary factor determining feed buoyancy is starch content and processing. For extruded feed:

10% starch for sinking feed

20% starch for floating feed

Process control (temperature, moisture, screw speed) fine-tunes expansion

Pellet mills, with only compressive force, cannot gelatinize starch to create floating feed, limiting their application for species like tilapia and catfish which require floating pellets for surface feeding.

Advantages of Modern Extrusion Technology

Extrusion not only shapes the pellets but also improves feed safety, digestibility, and nutrient retention. High temperature and pressure kill bacteria, while precise control of moisture and shear ensures minimal vitamin loss. Additionally, extruded pellets produce fewer fines, enhancing feed utilization efficiency and lowering the feed conversion ratio (FCR) in aquaculture operations.

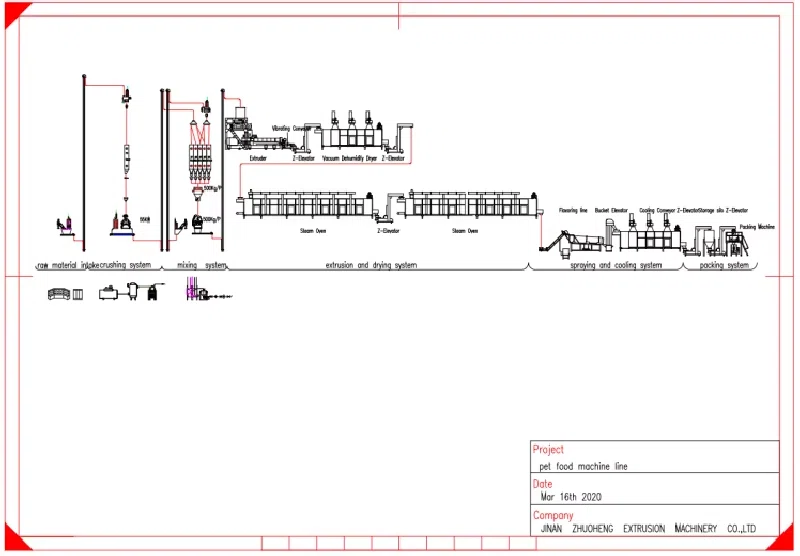

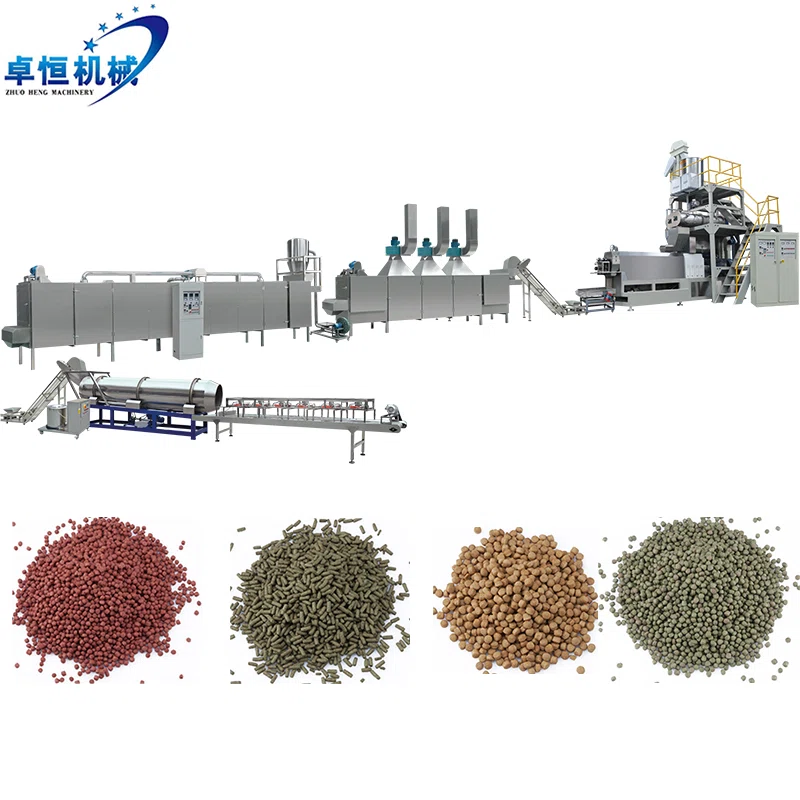

Our advanced Fish Feed Production Line integrates extrusion, drying, and coating systems to produce consistent, high-quality feed tailored to your operation’s needs. Learn more about our Food Processing Machine solutions.

Economic Considerations

While extruders have a higher initial cost compared to pellet mills, they offer:

Higher feed efficiency (lower FCR)

Ability to use higher fat content ingredients

Greater versatility for different species

Reduced waste and fines

Pellet mills remain cost-effective for small farms or low-fat sinking feed production, but for large-scale operations seeking efficiency and high-quality feed, extrusion is generally more profitable over time.

Case Example: Upgrading from Pellet Mill to Extruder

A mid-sized aquaculture client switched from a traditional pellet mill to an extruder system. The upgrade resulted in:

20% improvement in feed conversion ratio

Stable floating feed for surface feeders

Reduced labor and maintenance due to integrated production line

Ability to incorporate higher fat and protein ingredients

FAQ – Common Questions About Fish Feed Extrusion vs Pellet Mill

-

Q1:Can a pellet mill produce floating feed?

A:Not effectively. The compressive method cannot reduce bulk density sufficiently to achieve floatation.

-

Q2:Which is better for large-scale operations?

A:Fish Feed Extruder is more suitable due to higher versatility, improved digestibility, and better feed utilization.

-

Q3:Are extruders more expensive than pellet mills?

A:Yes, the initial investment is higher, but extruders often reduce feed cost per kg over time due to higher FCR efficiency.

-

Q4: Can we switch from pellet mill to extruder using existing line?

A: Yes, with proper system integration and equipment upgrades, your existing line can be converted for extrusion-based feed production.