In the aquaculture industry, feed quality is everything. Whether you’re a commercial fish farm or a mid-sized animal feed producer, investing in an Fish Feed Production Line can drastically improve the nutritional quality, digestibility, and efficiency of your operations. But what exactly is an extruded feed line, and how does it outperform traditional pelleting methods?

Why Choose Extrusion Technology in Fish Feed?

Compared to standard pelleting, extrusion uses high temperature, pressure, and moisture to “cook” the feed ingredients. This creates expanded feed pellets that are not only more palatable but also significantly more digestible.

Improved Nutrition: The high-temp process denatures anti-nutritional factors and improves protein availability.

Floating Capability: Especially critical for surface-feeding fish species like tilapia, catfish, and trout.

Less Waste: Floating pellets allow for precise feeding control, reducing waste and water pollution.

Sterilization Effect: Kills bacteria and fungi during processing.

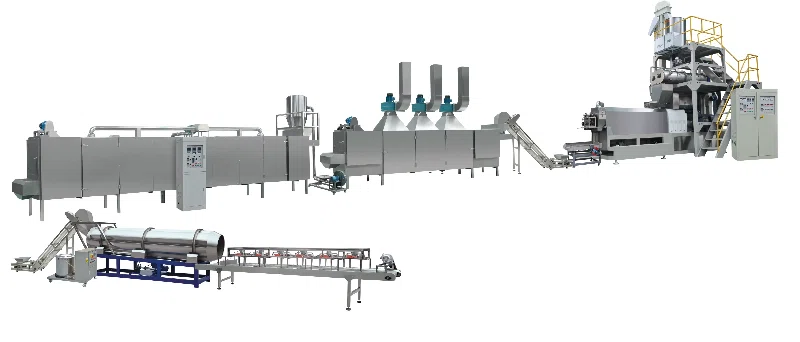

Key Components of a Fish Feed Extrusion Line

A typical Fish Food Extruder line includes several stages, each designed for specific purposes. Here’s a breakdown of our customized system:

Feeding System: Regulates uniform feeding with speed control.

Crusher & Mixer: Reduces raw materials like corn, soybean, fish meal into consistent particles.

Extrusion Chamber: High temperature (120-150℃) & pressure generate low-density, floating feed.

Dryer: Belt dryer lowers pellet moisture to ideal storage level.

Oil Spraying: Improves palatability with nutritional oils and vitamins.

Cooling System: Prevents crumbling, enhances durability.

Packing Machine: Automates bagging for efficient logistics.

Dry vs. Wet Type Extruder — Which One Fits You?

Both dry and wet-type extruders can be used for Fish Feed Production Line setups. Here’s how to choose:

| Type | Features | Suitable For |

|---|---|---|

| Dry Type | No boiler required, lower cost, suitable for small & medium farms | Startups, small feed plants |

| Wet Type | Steam-injected, better expansion, higher output, requires boiler | Commercial fish farms, pet food plants |

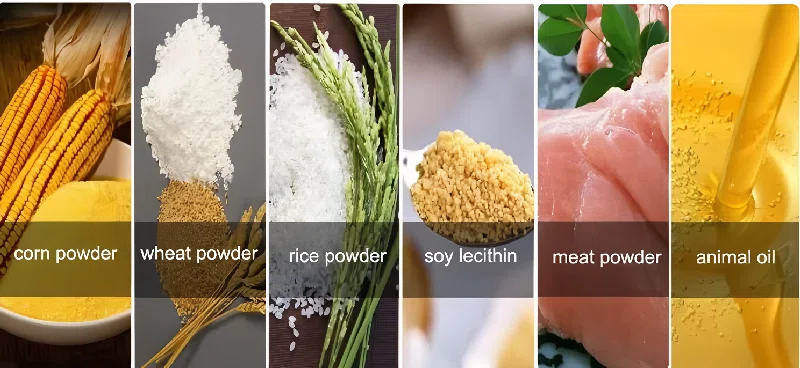

Raw Materials: What Goes In

Our systems can handle a wide variety of materials, such as maize, soybean meal, rice bran, wheat flour, fish powder, cassava, and even feather meal. Plant-based ingredients generally puff better than animal-based.

Our Turnkey Solution for Fish Feed Manufacturing

At Zhuoheng® we don’t just sell machines—we design full-scale Fish Food Processing Equipment lines tailored to your material, capacity, and budget. From 100 kg/h to 5 T/h, our machines cover the entire workflow, from crushing to packaging. Clients in over 30 countries rely on our expertise, installation service, and remote commissioning support.

Additional Benefits of Using Our System

Uniform pellet size & adjustable shapes

PLC automation & alarm system

Low energy consumption with high efficiency

Flexible mold switching for multi-species feed

Real-World Application: Customer Success in Nigeria

One of our most successful case studies comes from a mid-sized fish farm in Lagos, Nigeria. Before switching to our Fish Feed Production Line, the farm struggled with inconsistent feed quality and high import costs. After adopting our 300kg/h Fish Food Extruder system and customized floating feed molds, they reported a 27% increase in feed conversion efficiency and reduced their overall feed cost by 19% in just six months.

This example proves how localized feed production not only cuts operating expenses but also improves the quality and consistency of feed, leading to healthier, faster-growing fish stock.

Cost Savings & ROI Breakdown

Cost is a major concern for every aquaculture investor. Here’s a simplified ROI estimate based on a typical 500kg/h system:

| Category | Cost | Annual Savings | |

|---|---|---|---|

| Imported Feed (pre-installation) | $80,000/year | - | |

| Local Production via Extruder | $38,000/year | $42,000 | |

| Equipment Investment | $26,000 (one-time) | - | |

| Payback Period | < 8 months | ||

With such ROI, the shift to a Fish Food Processing Machine is not just a production upgrade—it’s a strategic investment.

Download Brochure or Request Free Consultation

Ready to Start Your Own Feed Line?

Download our product catalog or contact our team for a custom layout and business proposal tailored to your region, species, and budget.

📩 Download→ Full Catalog

Q&A: Fish Feed Extrusion Line

Is extruded feed really better than regular pellet feed?

Yes. Extrusion improves digestibility (by 10–35%), eliminates pathogens, and creates stable, floatable feed that reduces waste and improves feeding observation.

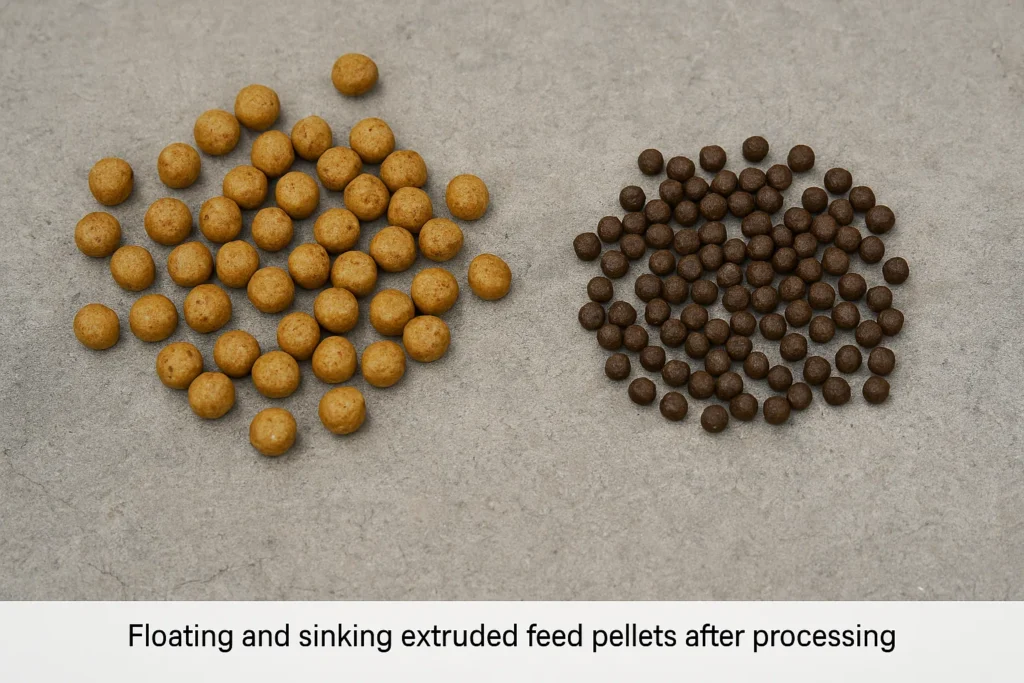

How do I choose between floating and sinking feed?

Floating feed is ideal for surface-feeders like tilapia, catfish, and trout. Sinking feed is preferred for bottom-feeders. Our equipment supports both.

What capacity should I choose for my farm?

It depends on your daily feed demand. For small farms, 100–300kg/h machines are suitable; commercial operations may require 1–2 tons/hour systems.

Can I use the same line to make pet food?

Absolutely. Just switch the molds and adjust formulas. Our Fish Food Extruder also supports dog and cat food production.

Do you offer installation and technical support?

Yes, we provide on-site and remote commissioning, training, and lifetime technical consultation.