In the high-stakes world of food service and commercial pasta production, “handmade” is often a marketing term used to describe quality. However, there is a fine line between “artisanal” and “inefficient.” As a factory that has spent decades designing custom food production lines, we have seen countless small businesses reach a plateau where their growth is physically throttled by manual labor.

If you are a restaurant owner, a boutique pasta wholesaler, or a startup food processor, the decision to invest in a Small Commercial Pasta Machine is not just an equipment upgrade—it is a strategic pivot. In this comprehensive guide, we will break down the technical, financial, and operational reasons why moving from manual to electric is the ultimate “game changer” for your business.

The Reality of Scaling: Why Manual Rollers Fail Businesses

Manual pasta makers are beautiful tools for teaching a child how to make tagliatelle on a Sunday afternoon. But in enterprise environment, they are a liability.

The Labor Trap

When you use a manual machine, your most expensive asset—human labor—is tied to a repetitive mechanical task. If you are paying a chef or a technician to turn a crank for four hours, you are essentially paying for a “human motor.” An Automatic Pasta Machine frees that person to focus on high-value tasks like recipe development, quality control, or client acquisition.

The Problem of "Inconsistent Force"

Manual rolling relies on human arm strength, which fluctuates. As the operator gets tired, the speed of the rollers changes, and the tension on the dough varies. This leads to microscopic inconsistencies in dough density. For a small business, this means one batch might cook in 3 minutes, while the next takes 4. In a professional kitchen, that 60-second difference is the difference between a 5-star review and a returned plate.

Technical Superiority: The "Industrial Heart" of the Machine

To understand why a Professional Pasta Machine for Small Business outperforms a manual one, we need to look under the hood. As manufacturers, we focus on the mechanics that retail bloggers often miss.

Torque vs. Speed

Manual machines rely on speed. High-end Automatic Pasta Machines rely on torque. Our industrial motors are designed to maintain a constant, high-pressure extrusion even when the dough is “hard” (low hydration). Harder dough often results in a better al dente texture, but it is nearly impossible to process by hand.

Heat Management and Dough Integrity

A common issue with cheap electric makers is that the friction from the motor heats the dough, essentially “pre-cooking” the starch before it even hits the boiling water. A Heavy Duty Pasta Maker for Home or small business from a professional factory includes specialized cooling systems—often water-cooling jackets around the extrusion head—to keep the dough at the optimal temperature (under 45°C/113°F). This preserves the natural color and nutrient profile of the wheat.

Material Science: Bronze vs. Teflon Dies

One of the biggest advantages of upgrading to a Small Commercial Pasta Machine is the ability to use professional-grade dies. This is where the “texture” of your brand is born.

Bronze Dies (The Artisanal Choice): These create a rough, porous surface on the pasta. Why does this matter? Because sauce clings to a rough surface. This is the hallmark of high-end Italian pasta. Manual machines usually use smooth chrome rollers that make the pasta “slippery,” causing sauce to slide off.

Teflon Dies (The High-Speed Choice): If you are producing pasta for a fast-food chain or a school lunch program, Teflon dies allow for incredibly fast extrusion and a smooth, consistent finish that dries quickly and resists breakage.

As a factory, we can customize these dies for you. If you want a specific shape that represents your local culture or a unique “flower” shape for a brand, we can CNC-machine a custom die specifically for your Tabletop Pasta Extruder.

Compliance and Food Safety

When you sell to supermarkets or export to Europe and North America, “it looks clean” is not enough. You need to meet international standards.

SUS304 Stainless Steel

Many entry-level “electric” machines use plated steel or plastic parts. In a commercial environment, these will chip or rust. Our Semi-Automatic Noodle Machine is constructed entirely of food-grade SUS304 stainless steel. It is resistant to the acids in eggs and the minerals in water, ensuring it never leaches heavy metals into your product.

Global Certifications (CE, NSF, UL)

A manual machine doesn’t need a safety rating. A commercial one does. We ensure our equipment meets:

CE Certification: For the European market.

Emergency Stop Protection: To prevent workplace injuries.

IP65 Waterproofing: On the control panels, so you can deep-clean the machine without frying the electronics.

The Financials: A Deep Dive into ROI

Let’s look at the numbers. Most of our clients are processing enterprises that need to justify every cent of capital expenditure.

Scenario: A Small Pasta Workshop

Manual Production: 2 employees producing 5kg per hour. Daily output (8 hours): 40kg. Labor cost: $320/day (at $20/hr).

Automated Production: 1 employee overseeing a Small Pasta Maker producing 20kg per hour. Daily output (8 hours): 160kg. Labor cost: $160/day.

Result: You have quadrupled your output while halving your labor cost. The machine essentially pays for itself in less than 45 days of full operation.

Beyond labor, you also reduce waste. A Pasta Making Machine is designed to leave minimal “dead dough” in the chamber, ensuring your raw material costs (Semolina, eggs, etc.) are optimized.

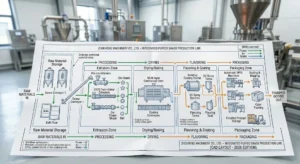

Integration: From a Machine to a Production Line

As a custom machinery factory, we don’t just see a single machine; we see a workflow. For a processing enterprise, the Automatic Pasta Machine is the heart, but it needs a body.

The Modular Approach

When you buy from a specialized manufacturer, you can scale your line as you grow:

Phase 1: The Extruder (Produces the pasta).

Phase 2: The Automatic Cutter (Ensures every noodle is exactly 25cm long).

Phase 3: The Trabatto (A vibrating pre-dryer that prevents the pasta from sticking together).

Phase 4: The Drying Cabinet (To create shelf-stable dried pasta for retail).

We specialize in ensuring that your Professional Pasta Machine for Small Business can be integrated with conveyors and packaging systems later on. This “future-proofing” is something you will never get from a retail store.

Recipe Versatility: Beyond Traditional Flour

The modern market demands more than just “White Flour Pasta.” With a Tabletop Pasta Extruder, you can handle heavy, difficult ingredients that would break a manual machine:

Gluten-Free Flour: Rice, corn, or chickpea flours are often “gritty” and require high pressure to bind.

Superfood Additives: Incorporating spirulina, beetroot juice, or activated charcoal requires precise mixing, which our vacuum-mixing chambers handle perfectly.

High-Fiber Whole Grains: These flours have sharp husks that can wear down inferior rollers; our hardened steel screws are built to resist this abrasion.

Conclusion: Don't Just Upgrade—Evolve

The choice between manual and electric is actually a choice between being a “hobbyist” and being a “business.” A manual machine is a tool for a person; a Small Commercial Pasta Machine is a tool for an enterprise.

By investing in automation, you are investing in the ability to say “Yes” to bigger orders. You are investing in the peace of mind that comes with knowing Batch #1 and Batch #1000 will be identical. Most importantly, you are choosing a partner in production that understands the technical nuances of food processing.

Q&A: Expert Answers for Your Pasta Production

-

1. How much space do I need for a commercial setup?

A: Not much! A Tabletop Pasta Extruder typically has a footprint of about 0.5 to 1 square meter. It is designed to fit on a standard commercial kitchen prep table. However, remember to leave space for a drying rack or a small pre-dryer if you are doing high-volume production.

-

2. Does an electric machine change the flavor of the pasta?

A: It actually improves the "sauce-ability." Because our machines use bronze extrusion dies, the pasta has a rougher texture than the smooth, pressed pasta from a manual roller. This texture is highly prized by chefs because it holds onto sauce much better, leading to a superior flavor experience for the customer.

-

3. Can the machine run 24/7?

A: While our Professional Pasta Machine for Small Business is "Heavy Duty," we recommend a 30-minute cooling break every 4-6 hours of continuous operation to maximize the lifespan of the motor. For true 24/7 operation, we recommend our industrial-tier production lines.

-

4. Is it difficult to change the shapes (e.g., from Spaghetti to Macaroni)?

A: It takes less than two minutes. You simply unscrew the front ring, swap the die, and tighten it back up. This versatility is why many of our clients can offer 10+ different pasta shapes with just one machine.

-

5. What kind of electrical setup do I need?

A: Most of our small commercial models run on standard single-phase power (220V/110V), so no special industrial wiring is required. However, for our larger Semi-Automatic Noodle Machine models, we can customize the motor for three-phase power depending on your factory's requirements.

Do you have a specific pasta shape or a difficult ingredient you are trying to automate? Contact our engineering team today for a custom consultation on how to build your perfect production line.