If you sell puffed snacks to Walmart, export floating fish feed to the Middle East, or co‑pack high‑moisture meat analogues for vegan brands, equipment downtime and inconsistent texture cost real money. The double screw extruder machine—also known in R & D labs as a twin screw extruder food processing line—delivers the mixing intensity, shear control and throughput modern recipes demand.

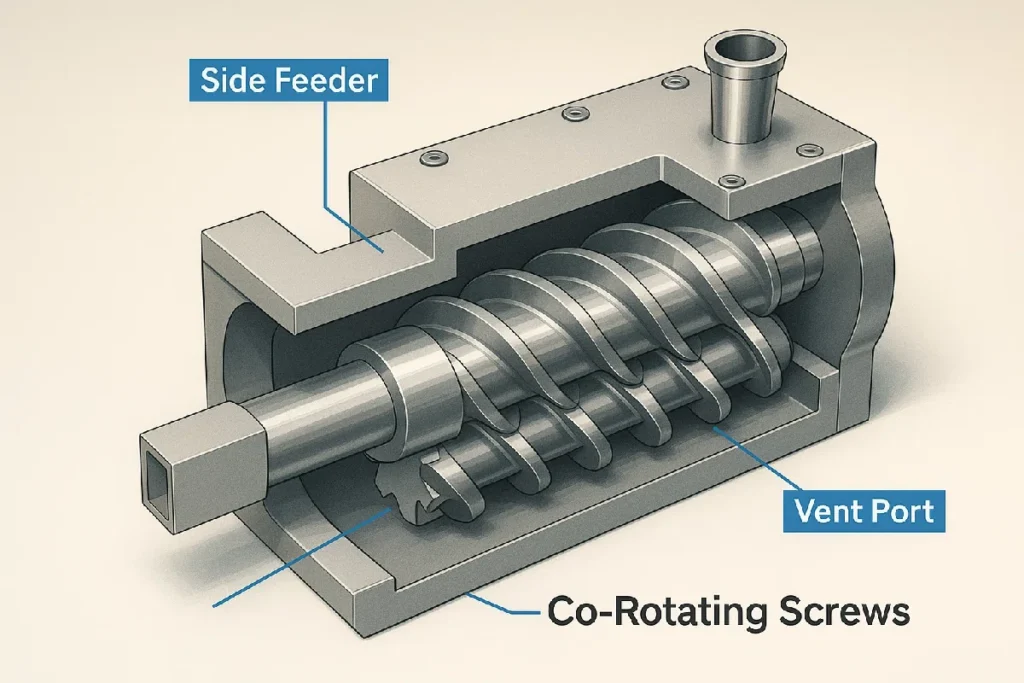

How Two Screws Beat One – Working Principle Recap

Unlike a single‑screw that drags material forward, a twin intermeshes inside a precision barrel to convey, knead, devolatilize and build pressure in one pass. Each screw element—conveying, kneading, reverse, or mixing—can be re‑stacked like Lego bricks to match starch gelatinisation curves or protein texturisation windows.

Think of it as a chef’s stand mixer married to a torque‑monster gearbox—except the ‘bowl’ sits at 140 °C and outputs six tonnes of premium kibble per shift.”

Configurations in Plain English

Co‑rotating vs Counter‑rotating

- Co‑rotating → higher shear; perfect for viscous, protein‑rich doughs.

- Counter‑rotating → gentle melt; ideal for fortified baby snacks and heat‑sensitive vitamins.

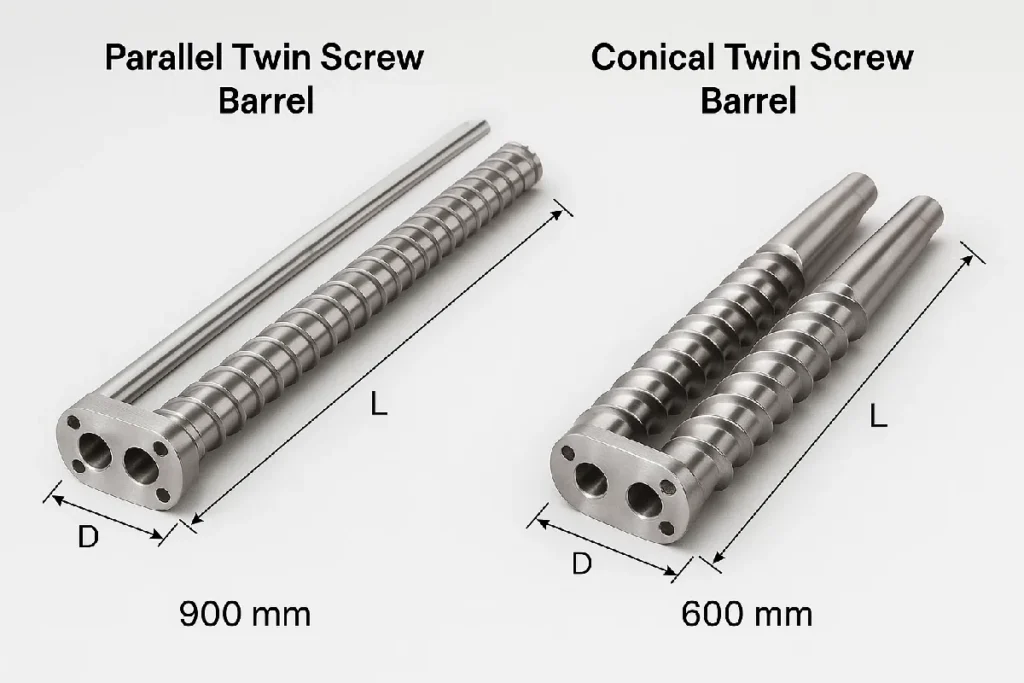

Parallel vs Conical Barrels

Parallel barrels give you longer L/D (up to 40:1) for intensive cooking and devolatilisation. Conical saves footprint and lowers melt temperature—handy when working with delicate plant proteins.

Eight Business‑Critical Benefits

25 % energy savings vs legacy single‑screw lines.

Zero “black specs” thanks to self‑wiping screw profile.

Quick recipe changeovers—go from corn snack to pea protein TVP in < 20 min.

Moisture down to 7 % with integrated vacuum venting—crispier texture, longer shelf‑life.

Modular side‑feeders unlock high‑value inclusions (freeze‑dried chicken, probiotics).

Industry 4.0 dashboard streams OEE and SEC in real time.

CE, UL and FDA contact‑surface compliance; smooth customs clearance worldwide.

Field‑reversible screw rotation for R&D flexibility.

Cost‑of‑Ownership & ROI (Real Numbers)

Segmented comparison:

| Legacy Single‑Screw 120 mm | Modern 75 mm Twin‑Screw | |

|---|---|---|

| CapEx (installed) | US $480 k | US $590 k |

| Throughput (kg/h) | 600 | 1 050 |

| Specific Energy (kWh/kg) | 0.32 | 0.21 |

| Annual Power Cost* | $138 k | $80 k |

| Payback | — | 2.1 years |

*Assumes 7 500 h/year; US industrial tariff 0.14 $/kWh.

Troubleshooting Cheat‑Sheet

Torque spike > 110 % → Check vent port clog, screw wear rings.

Surging output → Inspect feed PID loop or bulk‑density drift.

Excessive fines → Verify cutter speed sync, die‑plate temperature.

Burnt specks → Increase self‑wiping angle or shorten run length.

Case Study: Brazil – Pet‑Food Plant Boosts Throughput 22 %

Rio Feed S.A. switched from a 110 mm single‑screw to a 75 mm co‑rotating twin. In 90 days:

Throughput +22 % (18 → 22 t/day)

Specific energy −28 %

Moisture variability ±0.4 % (was ±1.5 %)

Compliance & Certification (Global Export Ready)

Our lines ship with:

UL 508A electrical panels for North America.

CE marking under EU Machinery & PED.

ISO 22000 hygienic design for food contact parts.

Weld traceability & PMI certificates.

Application Matrix – Where Twins Win

Ready to benchmark your energy cost against a modern double screw extruder machine? Schedule a virtual audit →

| Segment | End Product | Critical KPI | Recommended Screw Ø | |

|---|---|---|---|---|

| Aquafeed | Floating & sinking pellets | Bulk density ±20 g/L | 65‑85 mm | |

| Plant‑Protein TVP | High‑moisture chunks | Fibre alignment >80 % | 75 mm | |

| Breakfast Cereals | Wholegrain rings | Expansion ratio >3.0 | 50‑65 mm | |

| Pet Food | Kibble & treats | Protein integrity >75 % | 75 mm |

Quick Q & A

What is the main difference between single and twin screw extrusion?

A: Twin screws convey and mix simultaneously, giving tighter control over moisture, texture and residence time—critical for premium pet food and protein snacks.

How do I size a twin‑screw for pet‑food exports?

A: Add 30 % surge to weekly tonnage, divide by shifts, match kg/h to screw Ø 65‑85 mm.

Can I run gluten‑free and allergen‑safe recipes on the same line?

A: Yes—quick‑change screws & CIP barrels validate allergen switchover in 45 min.

Which utilities matter most?

A: Stable 3‑phase power, 15 °C chilled water, 6 bar compressed air.

Where can I watch a demo?

A: Live stream from our Jinan hub or on‑site trial.