In modern food manufacturing, efficiency, consistency, and versatility are not just advantages — they are requirements. One of the technologies that has empowered the food processing industry to meet these standards is the Food Extrusion Machine.

Whether you are producing pasta, cereal, pet food, or plant-based proteins, extrusion technology offers a powerful, scalable solution. But what exactly is this machine, how does it work, and why is it essential for processing companies worldwide? Let’s explore.

What Is a Food Extrusion Machine?

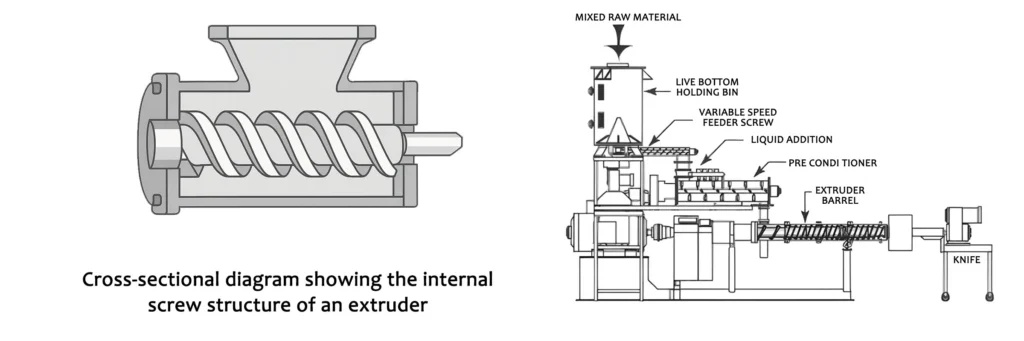

A food extrusion machine is an industrial bioreactor system that processes and shapes food materials by forcing a mixed blend of ingredients through a die — a narrow, specifically shaped opening — under high temperature and pressure.

This mechanism creates what’s known as an extrudate — the shaped, cooked product. The process combines mechanical shear, controlled heat, and moisture to cook and shape the raw materials continuously, making it one of the most efficient methods for producing uniform food products in bulk.

How Does a Food Extruder Work?

The extrusion process begins with raw ingredients, typically ground into coarse flour. These materials are first pre-conditioned with water, steam, or additives in a mixing chamber. Then, they are fed into the extruder barrel where rotating screws apply pressure and heat as the mix travels forward.

At the barrel’s end, the material is forced through a die, instantly releasing pressure and moisture. This causes the product to puff, expand, and take shape. The cut and dried extrudate is then ready for packaging or further processing.

Applications of Food Extruders in the Industry

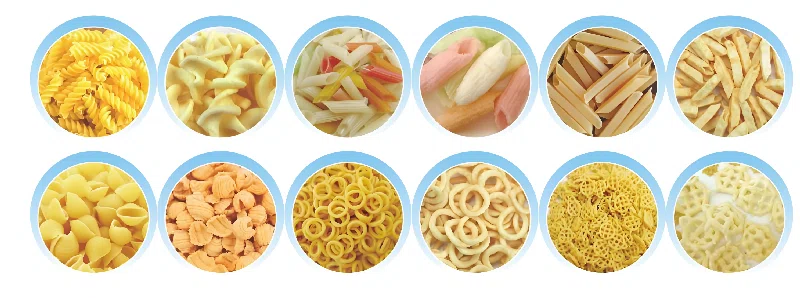

Extrusion cooking is now used to manufacture a wide range of products, including:

- Breakfast cereals and snacks

- Pasta and macaroni

- Pet foods and aquatic feeds

- Texturized vegetable proteins (TVP)

- Fortified rice analogs

As consumer demand increases for nutritious, shelf-stable, and visually appealing foods, the flexibility of extrusion has made it the go-to choice for many manufacturers.

Why Choose Zhuoheng's Customized Food Extruder Solutions?

At Zhuoheng Extrusion Machinery, we specialize in developing customized food extruder lines tailored to the specific needs of our global clients. Our machines feature:

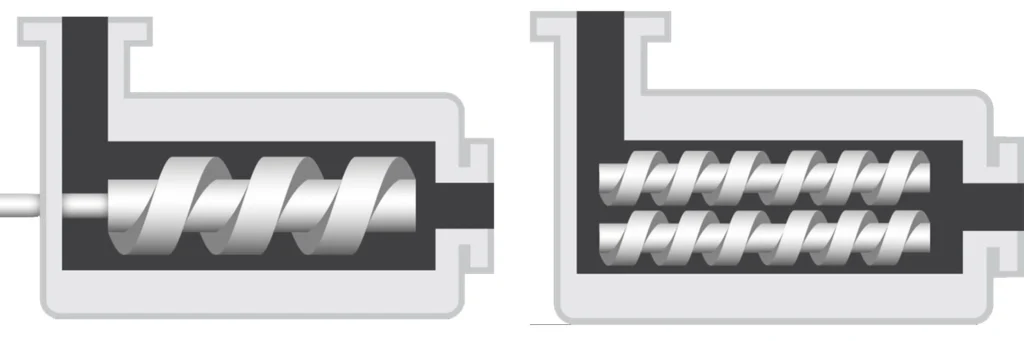

- Single or twin screw configurations

- Flexible die designs for multiple product shapes

- Precision temperature and moisture control

- On-site installation and technical support

Whether you’re launching a new production line or upgrading to meet higher demands, our extrusion systems provide the reliability and scalability you need.

Benefits of Using an Industrial Food Extrusion Machine

- High throughput and productivity — suitable for mass production with minimal waste

- Uniform product quality — extrusion ensures consistency in shape, color, and texture

- Energy-efficient — combines cooking, mixing, and forming in one continuous process

- Flexible formulation — works with grains, proteins, flours, and additives

What About Challenges?

While extrusion offers many advantages, it’s important to consider:

- Initial capital cost for high-quality extruders

- Learning curve for recipe optimization and temperature management

- Formulation sensitivity to moisture and salt content

This is where expert guidance and customized machinery become vital. At Zhuoheng, we not only deliver machines, but also support you in process design, operator training, and long-term maintenance.

FAQs About Food Extruders

What kind of food can be made using a food extruder?

Food extruders can produce snacks, cereals, macaroni, fortified rice, pet food, and even meat alternatives like textured soy protein.

Is extruded food healthy?

Yes, when properly formulated, extruded food retains nutrients and offers better digestibility. Fortified extrusion is often used for rice and baby food production.

What industries benefit from food extrusion technology?

Food manufacturers, pet food producers, agricultural co-ops, and meal replacement brands all benefit from extrusion’s efficiency and product variety.

How can I choose the right food extruder?

It depends on your product type, capacity needs, and ingredient composition. Contact Zhuoheng to get a tailored recommendation.