In today’s competitive food industry, building an efficient and reliable food production line is no longer optional—it’s essential. Whether you’re producing snacks, bakery products, pet food, or frozen meals, an optimized production line can dramatically improve your throughput, reduce labor costs, and ensure consistent product quality.

What Does a Food Production Line Include?

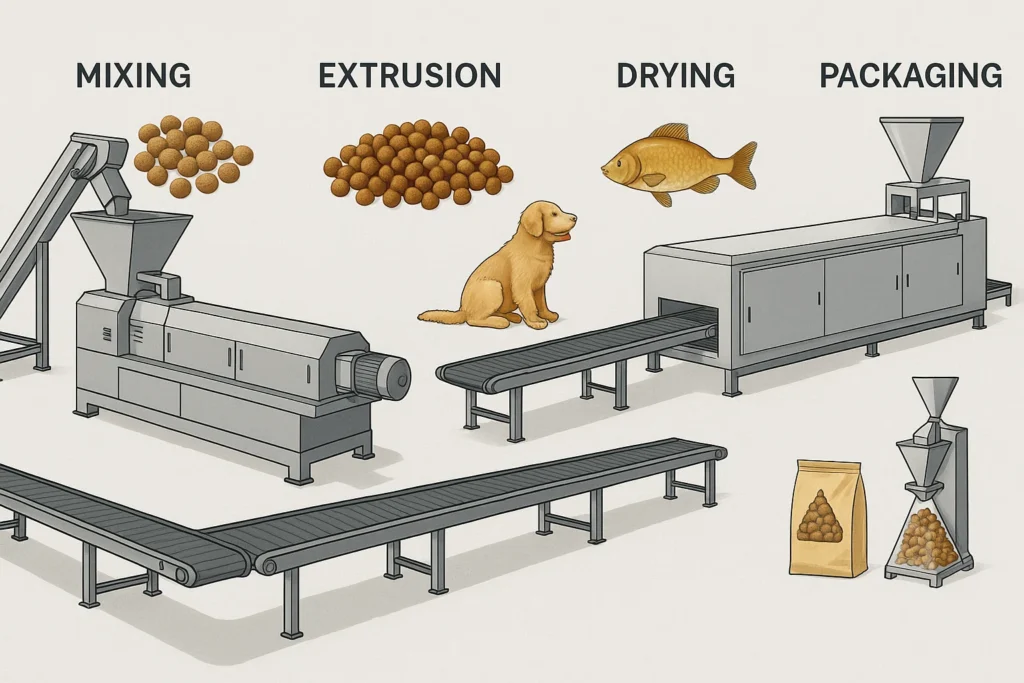

A complete production line is more than a few machines lined up—it’s an integrated system designed to turn raw materials into packaged products. This may include:

- Ingredient mixing and metering units

- Heating or cooking modules such as ovens or food extruders

- Shaping or molding systems

- Cooling or drying tunnels

- Packaging and labeling equipment

Why Efficiency Matters in Food Manufacturing

Increased production capacity, reduced energy consumption, and labor savings are just some of the benefits of automated food processing machines. But efficiency goes further—it ensures better product consistency, improved hygiene, and faster delivery to your market.

Customization Is the Key

No two production lines are alike. At Zhuoheng Food Machinery, we offer tailor-made solutions based on your food type, production scale, space, and budget. Whether you’re making puffed snacks, macaroni, pet food, or pasta, we configure each piece of equipment to match your needs.

Automation Reduces Human Error

With the help of advanced food extruder systems, automated lines reduce dependency on manual operations, lowering the risks of contamination or inconsistencies. It also frees up skilled workers to focus on monitoring and optimization.

Food Safety and Compliance

Hygienic design and compliance with international standards like HACCP, CE, and FDA are fundamental in our solutions. All Zhuoheng equipment is built with stainless steel and incorporates easy-to-clean structures, temperature controls, and CIP systems.

Sustainability in Food Production

Modern buyers demand greener operations. Our food processing machines incorporate energy-efficient motors, smart sensors for waste reduction, and systems designed to reuse heat and water where possible.

When Should You Upgrade or Invest?

If your current line is limited by capacity, fails to meet safety compliance, or struggles with maintenance downtime, it’s time to upgrade. Our team can audit your current setup and recommend improvements or a full upgrade plan.

Why Choose Zhuoheng?

We’re more than a manufacturer—we’re your engineering partner. With 15+ years of experience, hundreds of successful installations worldwide, and strong after-sales support, Zhuoheng ensures that your food production line investment brings long-term results.

Frequently Asked Questions (FAQ)

What is the difference between a food production line and individual food machines?

A food production line is a connected system where each machine plays a role in a continuous process, while individual food machines operate separately.

How much does a full food processing line cost?

Costs vary depending on capacity, complexity, and customization needs. Entry-level lines may start from $30,00, while large-scale lines can exceed $200,00.

Does automation mean zero labor is required?

No, but it significantly reduces manual involvement. Skilled operators are still essential for quality checks, maintenance, and system monitoring.

Can the line be modified later for new products?

Yes, most modern systems are modular. We at Zhuoheng offer upgradeable systems that grow with your business.

How long does installation and setup take?

Usually 10–30 days depending on complexity. Our engineers assist from design to on-site training.