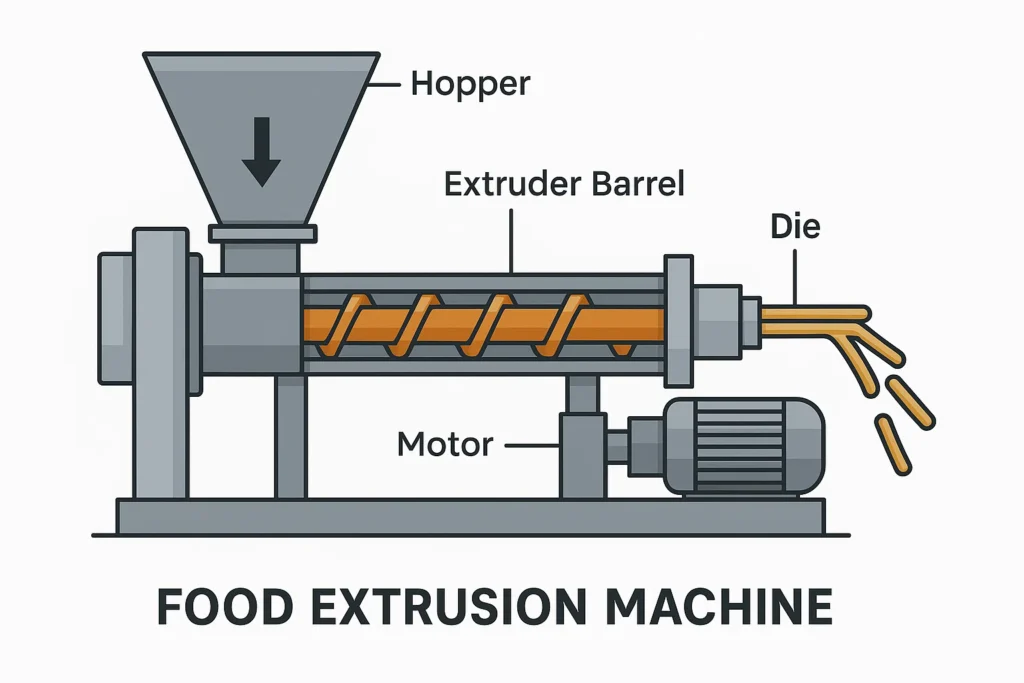

The term food extruder refers to a specialized machine that transforms raw ingredients into final food products by forcing them through a die using heat, pressure, and mechanical energy. It’s one of the most versatile and efficient technologies in modern food manufacturing, particularly used in producing pet foods, snacks, cereals, and meat alternatives.

The Basic Principle Behind Food Extrusion

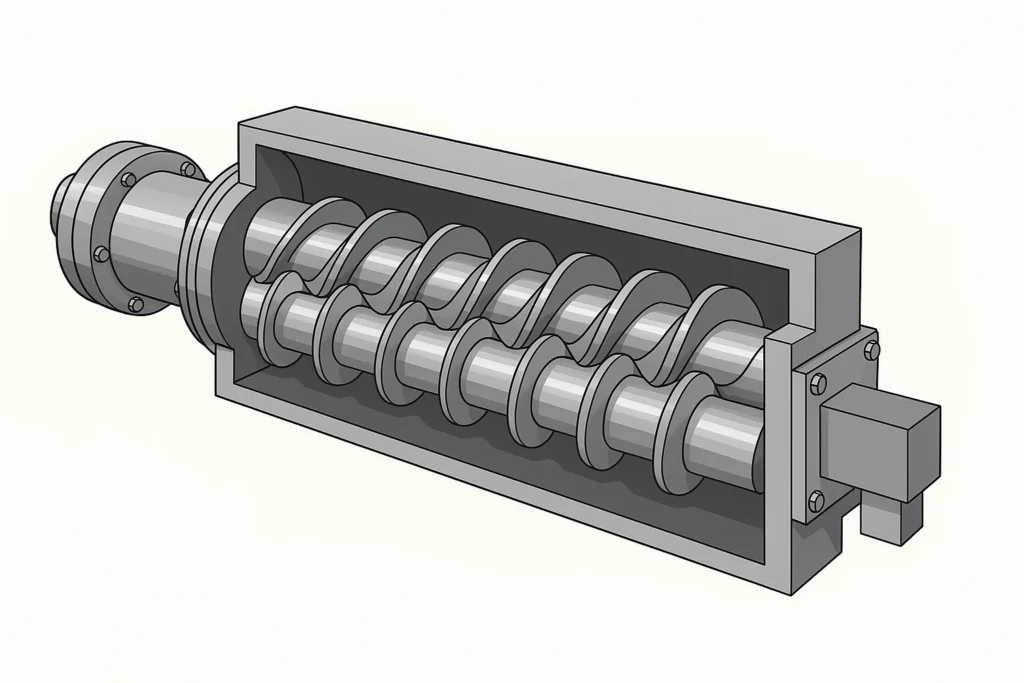

Extrusion works like a high-efficiency, short-time bioreactor. Raw materials—typically a mixture of starches, proteins, fats, and moisture—are fed into the machine. Inside the barrel, rotating screw(s) knead, mix, shear, and heat the ingredients until they melt into a viscous mass. Once pushed through a shaped die, the mass expands or forms into the desired structure.

Types of Extrusion Techniques

There are several types of extrusion techniques used, including:

- Cold extrusion: for shaping without cooking (e.g., pasta dough).

- Hot extrusion: involves thermomechanical cooking (e.g., pet food, snacks).

- Steam-induced expansion: used in puffed cereals and crispy snacks.

- Co-extrusion: produces dual-textured snacks with fillings.

What Can Be Made with a food extruder machine?

From dry dog kibble to puffed cheese snacks, food extruder machine enables the creation of:

- Pet foods (dry/wet for dogs and cats)

- Aquatic feeds (floating/sinking)

- Snacks (corn puffs, chips)

- Breakfast cereals

- Textured vegetable proteins (meat analogs)

- Third-generation half-snack products

Advantages for Food Processors

Using a food extrusion machine offers numerous benefits:

- Continuous operation with minimal labor

- Flexible product design & texture control

- Reduced water and energy usage

- Safe, hygienic processing

- Handles a wide range of raw ingredients

Why It’s Popular in Pet Food Manufacturing

Pet owners demand visually appealing, nutritious, and digestible foods. The extrusion process allows manufacturers to adjust shapes, textures, moisture levels, and nutrient delivery, aligning with premium pet food trends. Our company specializes in customized food processing machines that cater specifically to the pet industry, providing flexible solutions for floating, sinking, and soft-moist feed production.

Our Solution: Customizable Food Extruder Lines

At Zhuoheng Machinery, we offer scalable, modular systems tailored to your product type and capacity needs. Whether you’re a start-up looking to enter the pet treat market or a snack brand expanding to vegan options, our food processing machines deliver consistency, hygiene, and high ROI.

Common Questions About Food Extrusion

What is the difference between a food extruder and a pellet mill?

While both shape food/feed using dies, extruders cook and expand material using thermal and mechanical energy, while pellet mills use compression force with longer dies and often require binders.

Can a food extruder process fresh meat or high-fat ingredients?

Yes. With preconditioners and twin-screw designs, modern extruders can handle fresh meat slurry, oils, and high-moisture materials with precision and safety.

What maintenance is required for a food extrusion line?

Regular cleaning, screw replacement, and die inspection are essential. Our lines are designed for easy maintenance access and long-term reliability.

Can one extruder produce different products?

Absolutely. By switching die shapes and adjusting process parameters, a single extrusion line can produce a wide range of foods with varied textures.