From raw input to final kibble, this guide explains extrusion technology, equipment types, ROI considerations, and future trends. Designed for B2B buyers, processing companies, and investors evaluating Pet Food Production Line options.

What is Extrusion Technology?

Extrusion is a continuous cooking and shaping method where raw materials are mixed, cooked under pressure, and forced through a die to form the final kibble. This technology is preferred for pet food because it integrates cooking, sterilization, and shaping into one streamlined process. Unlike baking, extrusion allows precise control over moisture, density, and nutrient retention, resulting in high digestibility and consistent product quality.

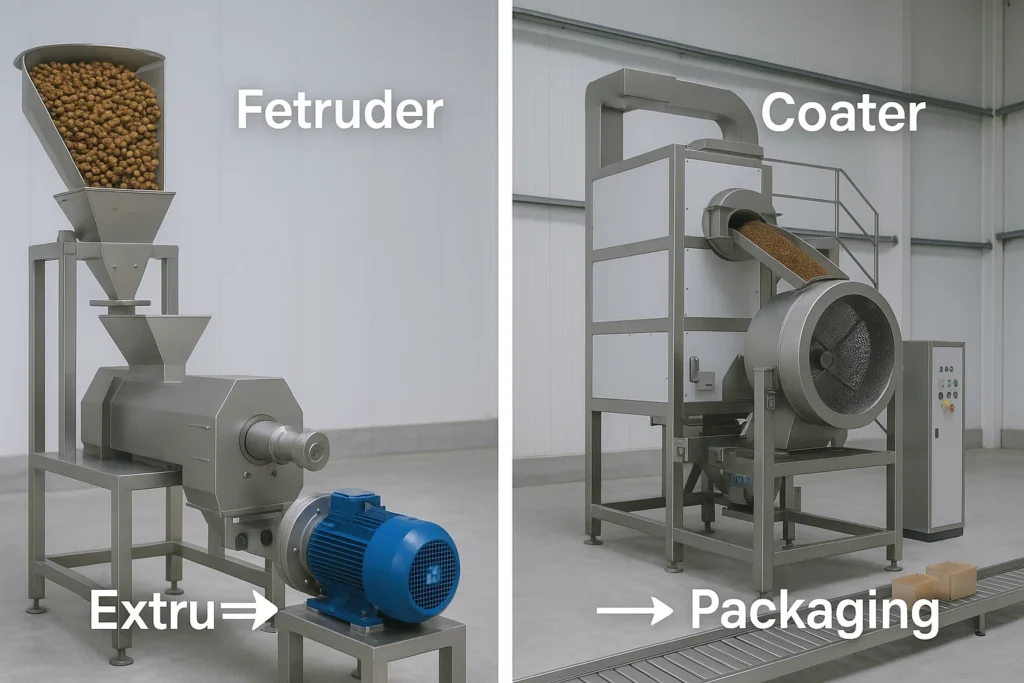

Step-by-Step: How the Process Works

- Feeding & Preconditioning: Ingredients such as grains, proteins, and vitamins are dosed and hydrated with steam/water.

- Extrusion & Cooking: Inside the barrel, screws apply shear and heat, gelatinizing starches and denaturing proteins.

- Die Shaping: The dough exits through a die, defining the kibble’s size and shape.

- Cutting & Drying: Rotary knives cut the kibble; dryers reduce moisture for shelf life.

- Coating & Cooling: Oils, palatants, and sensitive nutrients are added before cooling and packaging.

Integrated process: mixing, cooking, shaping, drying, and coating.

| Feature | Single-Screw | Twin-Screw |

|---|---|---|

| Complex Recipes | Limited | Excellent flexibility |

| Output | Low–Medium | Medium–High |

| Investment | Lower cost | Higher but versatile |

| Best For | Stable, dry kibble | Multi-protein, high-fat, specialty products |

Key Components & Controls

- Feeder & Preconditioner: stabilize mass flow, improve starch gelatinization

- Barrel & Screws: modular, stainless steel, high wear resistance

- Die & Cutter: customizable for product shapes

- Dryer: multi-pass with uniform airflow

- Coater: drum or vacuum systems for fats & flavors

- Control System: PLC + HMI for real-time monitoring

Maintenance & Safety Practices

- Daily dry clean; full wet clean weekly or after formula change

- Lubrication with food-grade oils every 200 operating hours

- Quarterly inspection of screws, dies, and seals

- Operator PPE: gloves, goggles, ventilation for dust/fumes

- Compliance: CE marking, HACCP, and OSHA/ISO 22000 standards

Consistent preventive maintenance increases extruder lifespan by 20–30% and reduces unplanned downtime.

Supplier Comparison & Industry Standards

| Aspect | Zhuoheng | GEA (Pavan) | Loyal | |

|---|---|---|---|---|

| Price | Mid-range, good value | High | Affordable | |

| Capacity | 200 kg/h–2.5 t/h | High capacity | Medium capacity | |

| Customization | Flexible dies & coating | Extensive | Limited | |

| Support | 24/7 online + on-site | Structured | Responsive |

Industry standards to check include AAFCO, FEDIAF, and ISO 22000, which assure compliance and export readiness.

Cost, ROI & Capacity Planning

Investment depends on output and automation level. Typical turnkey lines cost:

| Scale | Output (kg/h) | Typical Cost (USD) |

|---|---|---|

| Small scale | 200–400 | $45,000–$80,000 |

| Mid scale | 500–1000 | $120,000–$220,000 |

| Large scale | 1000–2500 | $350,000+ |

ROI for most buyers is 1–2 years, depending on local feed prices, electricity, and export margins. Energy-efficient extruders can reduce operating costs by up to 15% annually.

Future Trends: IoT, Sustainability, Protein Alternatives

- IoT Monitoring: Remote tracking of temperature, screw speed, and energy usage.

- Sustainable Protein: Capable of processing insect meal, pea protein, and algae-based ingredients.

- Energy Efficiency: Steam-assisted and low-energy dryers reduce carbon footprint.

- Customization: Rising demand for breed-specific or age-specific formulas.

Zhuoheng Solutions for Global Buyers

At Zhuoheng, we configure lines around your formulation and market. Whether you need a mid-size Pet Food Extruder for dry kibble or a high-capacity Animal Food Processing Machine for aquafeed, we deliver turnkey solutions. Our lines integrate smart controls, fast die changeovers, and vacuum coating systems to guarantee product consistency and palatability.

Ready to scale your production? Explore our Pet Food Production Line specifications and request a customized quote today.

FAQ — Frequently Asked Questions

How long does a typical extruder last?

With preventive maintenance, an industrial extruder lasts 10–15 years. Wear parts such as dies and screws are replaced periodically.

Can one line make both pet food and fish feed?

Yes. By adjusting moisture, screw profile, and dies, the same line can produce floating aquafeed or dense kibble.

How soon can I expect ROI?

Most buyers recover investment within 18 months, especially if exporting premium products with higher margins.

What certifications are needed?

CE marking, HACCP, and ISO 22000 are baseline. For exports to EU/US, compliance with AAFCO/FEDIAF is essential.

What if I need recipe support?

Zhuoheng offers pilot testing and lab services to help you validate new formulations with our Pet Food Processing Equipment.