Fish feed is the backbone of modern aquaculture. The right mix of ingredients determines not only the growth rate and health of the fish but also the profitability and sustainability of the farming operation. In today’s competitive aquaculture market, understanding what goes into fish feed—and how these ingredients are processed—is essential for every feed producer and seafood processor.

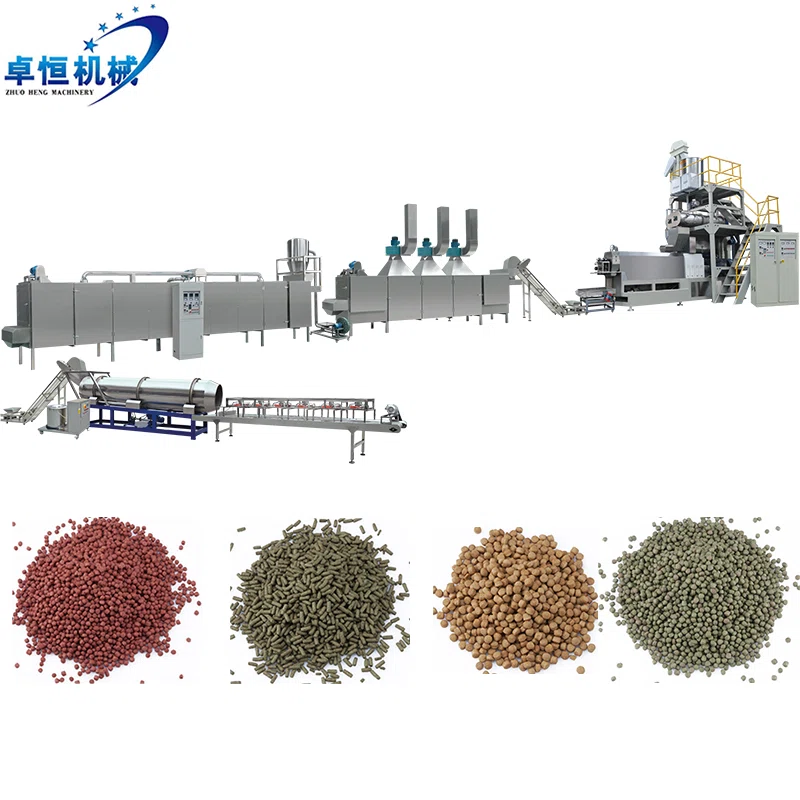

With modern automation and extrusion technologies, many processing plants have turned to advanced systems such as the Fish Feed Production Line to achieve precise quality control, higher yield, and consistent pellet performance.

1. The Core Composition of Fish Feed

Fish feed generally consists of three main nutritional groups: protein, lipids, and carbohydrates, with added vitamins, minerals, and additives for balance. However, the exact formulation depends on the species (carnivorous, omnivorous, or herbivorous), growth stage, and production goals.

High-quality protein sources like fish meal, soybean meal, and insect protein form the base of most formulations. Energy-dense oils, such as fish oil or rapeseed oil, enhance digestibility and flavor. Finally, grains like wheat or corn serve as both energy carriers and binding agents for pellet stability.

2. Traditional vs. Modern Protein Sources

Historically, fish meal was the gold standard for protein in aquaculture feed due to its high digestibility and amino acid profile. Yet, as global fishmeal prices rise and sustainability concerns grow, producers are increasingly turning to alternative proteins such as plant-based meals, insect protein, and single-cell organisms.producers are increasingly turning to alternative proteins such as plant-based meals, insect protein, and single-cell organisms (read more about alternative protein sources here).

Soybean meal offers a balanced amino acid profile and is widely available, making it a preferred choice in cost-effective feed formulations. Insect meal—particularly from black soldier fly larvae—has emerged as a sustainable, high-protein alternative with impressive growth efficiency and minimal land use.

Many advanced producers now use extrusion technology from Fish Food Processing Machine systems to enhance protein digestibility and deactivate anti-nutritional factors found in plant materials. Extrusion allows for better nutrient retention and longer shelf life.

3. Lipids and Energy Sources

Lipids provide the concentrated energy fish require for rapid growth and reproduction. While fish oil remains a premium ingredient, plant-based oils such as canola, soybean, and palm oil are increasingly replacing it due to cost and sustainability advantages.

Advanced control systems in Food Fish Processing Equipment allow manufacturers to fine-tune oil addition during extrusion, preventing oxidation and ensuring uniform coating on each pellet. This results in feed that maintains its nutritional profile even under prolonged storage.

4. Carbohydrates and Binders

While fish do not have high carbohydrate requirements, starches from wheat, corn, or rice bran serve as critical binders in feed manufacturing. During extrusion, starch gelatinizes—helping pellets maintain their shape and buoyancy. Floating or sinking feeds can be achieved by adjusting extrusion parameters such as temperature, moisture, and screw speed.

A well-calibrated Fish Food Extruder provides precise control over these variables, enabling producers to create customized feed types for various species—from floating feed for surface feeders to slow-sinking pellets for bottom dwellers.

5. Additives, Vitamins, and Minerals

Additives play an invisible yet powerful role in feed efficiency. Common examples include amino acids (like lysine and methionine), antioxidants, probiotics, and pigment enhancers. Each contributes to growth, immunity, and product quality.

For example, vitamins C and E enhance fish immunity, while carotenoid pigments improve color in ornamental and salmonid fish. By integrating these nutrients during extrusion, producers ensure uniform distribution across all pellets.

6. Sustainable and Innovative Feed Ingredients

Sustainability is reshaping the feed industry. Novel ingredients such as microalgae and single-cell proteins offer omega-3 benefits without relying on wild-caught fish. Agricultural by-products like rice bran and cassava peel reduce waste and feed costs.

Insect meal production, driven by automation, is rapidly scaling up as a future-ready protein source. Many factories now upgrade to Fish Feed Production Line systems to efficiently handle these new materials, achieving high digestibility and low nutrient loss.

7. The Role of Extrusion in Fish Feed Production

Extrusion is the heart of modern fish feed production. This high-temperature, short-time process ensures proper cooking, sterilization, and structural transformation of feed ingredients. During extrusion, starches gelatinize, proteins denature, and lipids emulsify — all of which improve digestibility and water stability.

The fish feed extruder allows operators to precisely adjust parameters such as barrel temperature, screw configuration, and moisture level. These factors determine pellet size, shape, density, and floating behavior. High automation ensures that each batch maintains uniform quality and reduces manual labor.

8. Automation and Quality Control

In today’s smart factories, automation is no longer optional — it’s the foundation of consistent quality and efficiency. Advanced Fish Feed Production Lines integrate sensors, programmable logic controllers (PLC), and real-time monitoring systems that continuously measure moisture, temperature, and extrusion pressure.

These intelligent controls not only optimize feed texture and nutrient retention but also minimize waste and energy use. With cloud-based systems, manufacturers can track production performance remotely, ensuring traceability and compliance with global feed standards.

9. Energy Efficiency and Environmental Impact

As energy costs and environmental awareness rise, feed manufacturers are prioritizing energy-efficient machinery and sustainable operation. Modern fish food extruders and dryers now feature heat recovery systems, variable frequency drives, and moisture control units that significantly reduce power consumption.

Moreover, many producers have shifted to renewable biomass or solar-assisted drying systems. This not only lowers carbon emissions but also aligns with the global aquaculture trend toward eco-friendly and resource-efficient production.

10. Future Trends in Fish Feed Formulation

The next decade will witness transformative innovation in fish feed. Artificial intelligence (AI) and big data are already being used to design optimized feed recipes based on species, environmental conditions, and growth data. Precision feeding systems, integrated with IoT-enabled feeders, are reducing waste while maximizing growth efficiency.

Additionally, 3D-printed feed pellets are emerging for research and specialized diets, allowing precise control of nutrient layering. With the rise of circular economy models, more feed producers will integrate waste-to-protein technologies — converting agricultural and food waste into valuable feed resources.

11. Choosing the Right Fish Feed Production Line

Selecting a suitable Fish Feed Production Line depends on production scale, feed type (floating, sinking, slow-sinking), ingredient composition, and automation level. Key components include a mixer, screw conveyor, extruder, dryer, flavoring drum, and cooling system.

Manufacturers should look for systems that provide flexible parameter control, durable build quality, and after-sales technical support. Partnering with experienced equipment suppliers ensures efficient setup, cost control, and consistent feed quality over time.

12. Conclusion

The fish feed industry is evolving faster than ever — from traditional protein sources to smart automation and sustainable innovations. The right mix of raw materials, combined with efficient processing technology like the fish food extruder, defines the future of profitable and responsible aquaculture.

By adopting modern fish feed production lines, feed producers not only meet the nutritional demands of aquatic species but also contribute to a more efficient, eco-friendly, and resilient global food system.

FAQ — Frequently Asked Questions

-

Q1: What is the best protein source for fish feed?

It depends on the fish species. Carnivorous fish prefer animal-based proteins like fish meal, while herbivorous species thrive on plant-based sources such as soybean or rice bran.

-

Q2: How do I choose between floating and sinking feed?

Floating feed suits surface feeders like tilapia, whereas sinking feed is better for bottom dwellers like catfish. The feed type is determined by extrusion temperature, moisture, and screw design.

-

Q3: Is insect protein a viable alternative to fish meal?

Yes. Insect protein offers high digestibility, sustainable sourcing, and reduced environmental footprint, making it a promising alternative for the future.

-

Q4: Can extrusion improve feed shelf life?

Absolutely. The high-temperature short-time process of extrusion destroys pathogens and stabilizes moisture, significantly extending storage stability.