Why this question matters now

The aquaculture industry sits at a crossroads. Feed is the single largest line item in farmed-fish production costs, wild forage fisheries are under pressure, and buyers — from retailers to end consumers — are demanding more sustainable protein. The practical question many feed manufacturers and processing plants face is simple and urgent: Can I blend plant or insect protein into fish feed to cut costs and meet sustainability goals without sacrificing fish performance?

Short answer: yes — but only when you treat formulation, processing, and quality control as a single, integrated system. This article gives feed producers, B2B buyers, and processing companies the practical, technical, and commercial guidance they need to evaluate, formulate, and produce high-performance feeds that include plant and insect proteins.

Executive summary — what you will learn

How plant, insect, and microbial proteins compare nutritionally to fishmeal

The real technical risks (antinutritional factors, amino acid imbalances, chitin, heavy metal uptake) and how to mitigate them

Why extrusion and modern processing technology changes the game — and which parameters matter

Practical substitution ranges and step-by-step rollout advice for fish feed production lines

Cost drivers and how to assess ROI when switching ingredients

A case-style example and a checklist your feed mill can use today

1. The big picture: Why fishmeal replacement is a strategic imperative

Global aquaculture expansion, volatile fishmeal prices, and environmental policy pressure create a strategic need to reduce reliance on marine-derived proteins. Fishmeal is nutritionally excellent, but supply constraints and ecological concerns mean the industry must diversify. Plant proteins (soy, pea, rapeseed, etc.), insect meals (BSF larvae, mealworm), and single-cell proteins (SCP — algae, yeast, bacteria) are all part of the toolbox. Each has tradeoffs — the task is to blend them in ways that preserve fish growth, feed conversion, and product quality while lowering costs and footprint.

Key performance metrics feed formulators monitor

Protein content (%) and true digestible protein

Essential amino acid profile (lysine, methionine, threonine, etc.)

Energy:protein ratio and lipid quality (omega-3s)

Feed conversion ratio (FCR) in the target species

Pellet water stability and hardness (important for extruded feed)

Biosecurity parameters (heavy metals, mycotoxins, pesticide residues)

2. Plant proteins — advantages, limitations, and processing solutions

Advantages

Cost-effective raw material and widely available

Predictable supply chains for many crops

Good protein concentrations after concentration or isolation (e.g., soy concentrate)

Main limitations (and why they matter)

Anti-nutritional factors (ANFs): phytic acid, trypsin inhibitors, lectins, tannins. These reduce digestibility, bind minerals, and can depress growth if unaddressed.

Amino acid imbalance: many plant proteins are low in methionine (and sometimes lysine), necessitating supplementation.

Digestibility: raw plant meals often have lower in vivo digestibility vs. fishmeal due to fiber and ANFs.

Sustainability caveats: some plant sources (e.g., soy) are linked to deforestation if not certified.

Processing & formulation solutions

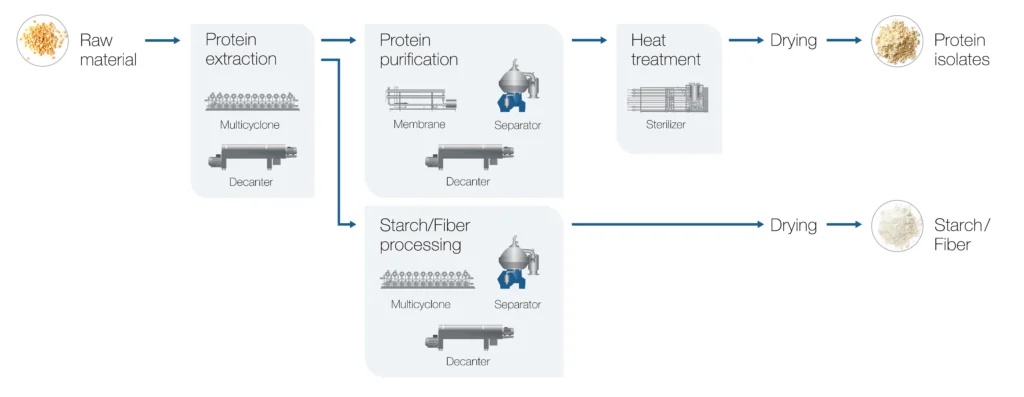

Thermal processing / extrusion: high-temperature short-time (HTST) extrusion reduces many ANFs, improves starch gelatinization and protein denaturation, and increases bioavailability.

Enzymatic treatments and fermentation: microbial fermentation (Bacillus, Aspergillus) reduces ANFs, increases soluble protein, and sometimes enhances palatability.

Amino acid supplementation: add crystalline methionine, lysine, threonine to rebalance diets.

Blending strategy: combine two or more plant sources (e.g., soy + pea) to complement amino acid profiles.

3. Insect proteins — the rising star, with nuances

Nutritional strengths

High crude protein (40–60% DM for many insect meals) with a favorable essential amino acid profile for many species.

Rich in medium-chain fatty acids (e.g., lauric acid in BSF) and micronutrients (iron, zinc).

Natural bioactive compounds (antimicrobial peptides) can support gut health.

Primary limitations and management

Cost: currently higher than bulk plant meals but falling quickly with scale.

Chitin content: exoskeletons contain chitin which can reduce apparent protein digestibility in some species; chitinase activity varies across fish. Techniques such as defatting, chitin reduction, or enzymatic pre-treatment improve utilization.

Substrate safety: feed substrate quality determines heavy metal/pesticide risks — strict substrate controls and testing regimes are essential.

Lipid and PUFA profile: insect lipids are not rich in long-chain omega-3 (DHA/EPA) — complementary algae oils are often used to balance lipids in marine fish diets.

Practical substitution guidance (general rules)

Omnivores (tilapia, carp): insect meal can replace up to 30–50% of fishmeal under controlled trials — start low and monitor.

Carnivores (salmonids): start with 10–20% replacement and supplement with DHA/EPA-rich oils if needed.

Use defatted insect meal when higher protein and lower lipid content are required for pellet quality.

4. Single-cell protein (SCP) & microalgae — concentrated nutrition and functional benefits

SCP from algae, yeasts, fungi, and bacteria can deliver excellent amino acid profiles, functional vitamins, pigments, and omega-3 precursors. Microalgae also supply DHA/EPA, making them ideal complements to insect and plant blends.

Benefits

High-quality protein (30–70% depending on organism)

Well-balanced EAAs and vitamins (including B12)

Possibility to grow on industrial CO₂ streams or waste substrates → strong circular economy case

Challenges and mitigations

Nucleic acid content in some SCPs requires formulations/processing to limit uric acid load in target species. Enzymatic or thermal processing reduces nucleic acids.

Cell wall digestibility: microalgae cell walls can be tough — mechanical disruption (bead milling, ultrasonication) improves nutrient access.

Cost & scale: still more expensive than conventional ingredients, but valuable at lower inclusion for functional benefits (immune stimulation, pigmenting, omega-3 enrichment).

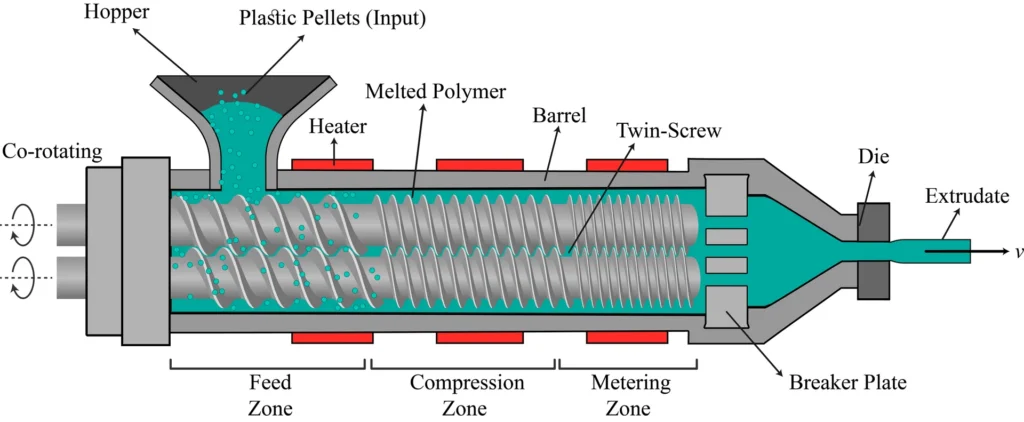

5. How extrusion technology changes the feasibility of blends

Extrusion is the backbone of modern feed processing. The right extruder transforms a heterogeneous mix of plant, insect, and microbial ingredients into stable, digestible, and palatable pellets.

Why extrusion helps

ANF deactivation: heat and shear reduce many antinutritional factors.

Improved digestibility: gelatinization of starches and denaturation of anti-nutritional proteins improves enzymatic access.

Pellet water stability & floating/sink control: process settings create desired density and buoyancy.

Binding and texture: proper extrusion reduces fines and nutrient leaching.

Critical extrusion parameters (practical ranges & what to monitor)

Barrel temperature (°C): typical 120–160°C for full cooking of mixed feed — adjust lower for heat-sensitive additives.

Screw speed (rpm) and specific mechanical energy (SME): higher SME increases heat from shear — improves denaturation but can damage heat-labile vitamins.

Moisture content (%): 18–25% in feed mix before die for many formulations; higher moisture reduces mechanical shear but may affect expansion.

Die size and open area: control pellet diameter and density; small die openings increase torque and SME.

Preconditioning: steam and liquid addition time before the extruder influences starch gelatinization and protein denaturation.

Note: exact parameters must be validated for each recipe; pilot trials are essential.

6. Practical formulation strategy — step-by-step rollout for feed mills

Phase 0 — Preparation & risk assessment

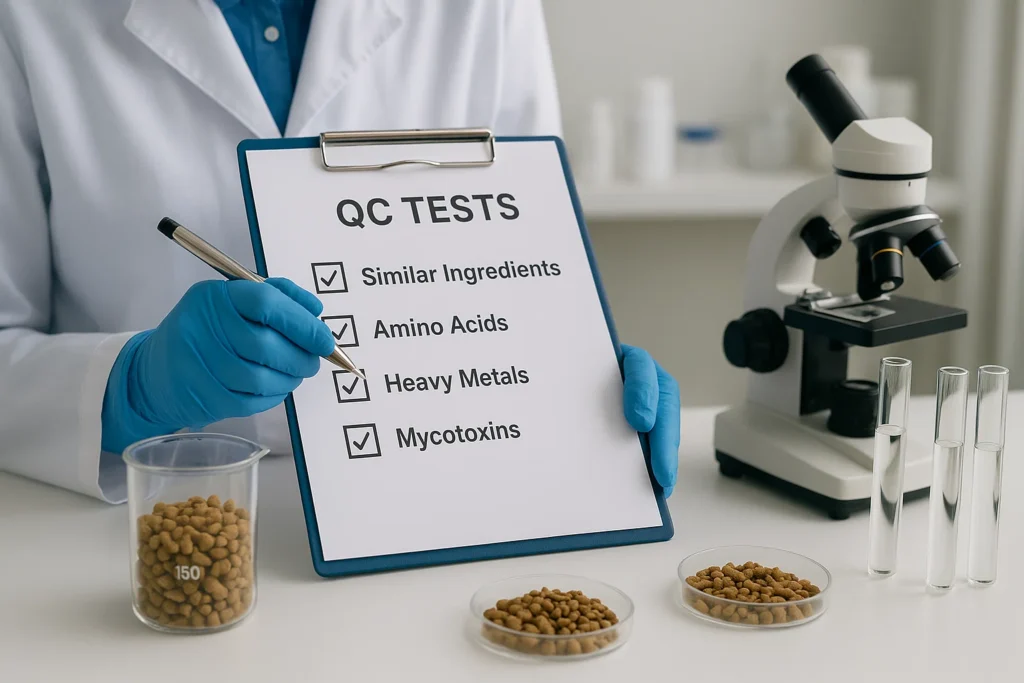

Audit ingredient suppliers (certificate of analysis, substrate controls for insects, pesticide/heavy metal testing for plant meals).

Lab analyze amino acid, moisture, ash, lipid, fiber, and anti-nutritional factor content.

Phase 1 — Trial blends in the lab

Start with conservative substitution (10–15% fishmeal replacement).

Use a blend: combine a plant protein + insect meal + microalgae or SCP for essential lipids.

Add crystalline methionine/lysine as needed.

Run small-batch extrusion with varying parameters to establish cook curve.

Phase 2 — Pilot scale & grow-out trial

30–90 day feeding trial on target species, monitor FCR, SGR (specific growth rate), survival, gut histology, and filet quality.

Assess pellet physical properties in water (disintegration, nutrient leaching).

Phase 3 — Commercial ramp-up

Scale up production in steps. Maintain rigorous QC for each incoming ingredient batch.

Track economics: ingredient cost per ton, FCR-driven feed cost per kg fish, and overall ROI.

7. Cost and ROI considerations — how to make the math work

A switch to blended proteins is not only a nutrition question — it’s a business decision. Plants typically offer the biggest immediate raw-material cost savings but may require additive costs (enzymes, AA supplements) and processing modifications. Insect and SCP ingredients may cost more on a per-ton basis but can improve FCR, immune status, and product value.

Example cost model (illustrative)

Fishmeal: $1,800/MT (volatile)

Soy concentrate: $700/MT

Defatted BSF meal: $2,500/MT

Algae meal (DHA source): $5,000/MT

If a baseline feed costs $1,200/MT with 30% fishmeal and FCR = 1.5, a hybrid formula that reduces fishmeal by 10 percentage points and adds BSF + algae for stability might change ingredient cost by +$30–$80/MT but reduce FCR by 0.05 — netting savings depending on sale price and mortality reductions. Do the math with your local costs and expected production figures.

Simple decision checklist

Ingredient availability and price stability?

Quality certificates and tested contaminant levels?

Processing capacity and extruder flexibility?

Market acceptance and labeling needs?

Pilot trial results (FCR, survival, growth)?

8. Case-style example (composite, anonymized, practical)

A mid-size feed mill in Southeast Asia wanted to reduce imported fishmeal use. They:

Audited local insect producers and selected defatted BSF meal with consistent CA.

Reformulated a tilapia grower diet: 20% fishmeal → 10% fishmeal + 8% BSF + 8% pea concentrate + 2% microalgae (DHA booster).

Adjusted extrusion parameters: barrel temp to 140°C; preconditioner steam increased; SME increased slightly for better cook.

Ran a 60-day grow-out: FCR improved from 1.60 → 1.55, survival unchanged, filet quality acceptable.

Ingredient cost rose marginally but feed-to-fish conversion improvement and local sourcing reduced supply risk, improving margins over 12 months.

Key learnings: stepwise substitution, strong supplier QA, and precise extrusion tuning made the program a success.

9. Critical quality-control and food-safety steps

Test incoming batches for heavy metals (Pb, Cd, Hg), mycotoxins, pesticide residues, and microbial load.

For insects: test feed-substrate provenance, absence of banned waste, and heavy metal content.

Adopt traceability: batch numbering from raw material to finished pellet.

Monitor pellet water stability, lipid oxidation indicators (TBARS), and organoleptic attributes.

10. Market and regulatory considerations

Be aware of local regulations on allowable substrates for insect farming and approvals for novel feed ingredients.

Labeling: if you market “sustainably produced” fish, ensure supply chain documentation supports claims.

Consumer perception: educational marketing (transparency on insect-fed fish safety and benefits) helps market acceptance.

11. Ready-to-use checklists for feed mill teams

Pre-trial checklist

Supplier CA, COA, substrate documentation (for insects)

Lab baselines: AA profile, ANF levels, lipid class, moisture, ash

Extruder capability report: max temp, SME range, die options

Trial-run checklist

Record extrusion parameters per batch (temp zones, screw speed, moisture)

Physical pellet tests: float/sink, disintegration, water uptake

Animal trial monitoring plan (FCR, SGR, histology sampling)

Commercial rollout checklist

Set QC acceptance thresholds for incoming materials

Pricing & inventory hedging plan

Marketing & labeling compliance

12. Practical FAQs (expanded & technical)

Q: What is a safe first step for a feed mill replacing fishmeal?

A: Replace 5–15% of fishmeal with a mixed alternative (plant + insect or plant + SCP). Run shorter grow-out trials and monitor FCR and gut histology. Only scale after consistent positive results.

Q: Will extrusion always remove anti-nutritional factors?

A: No. Extrusion greatly reduces many ANFs but does not eliminate all. Enzymatic pretreatment, fermentation, or additional heat treatments may still be needed for certain plant meals.

Q: How do I manage omega-3 levels when using insect meals?

A: Add microalgae-derived oils/meal at low inclusion (1–3%) to restore DHA/EPA in marine species diets; freshwater omnivores often need less.

Q: Are there certification schemes for insect meals?

A: Yes — look for suppliers with feed-grade certifications, substrate control, and third-party lab testing. Industry standards are evolving; prioritize traceability.

13. Closing practical recommendations

Start small and measure: incremental substitution with clear KPI tracking is the least risky path.

Treat processing and formulation as one system: ingredient selection dictates extrusion settings and vice versa.

Use mixed-source blends: combining plant + insect + SCP typically gives the best blend of cost, functionality, and nutrition.

Invest in QC and supplier audits: the weakest link is often raw-material variability.

Consider equipment upgrades: modern twin-screw extruders and full automatic mixing/conditioning lines make ingredient changes far easier.

14. Full-text checklist (one-page takeaway for operations teams)

Audit suppliers → lab test → run lab extrusion → pilot grow-out → scale with QC gates.

Monitor: FCR, SGR, survival, pellet physical quality, contaminant tests.

Keep records: ingredient batch → processing params → fish performance → market results.

15. Final thought

Blending plant and insect proteins into fish feed is not an experiment any more — it is a practical path to a more resilient, lower-impact industry. The technical hurdles are real, but they are solvable with the right combination of formulation science, robust processing (extrusion), and careful quality control. For feed mills and processing factories, the transition is both a challenge and an opportunity to optimize cost, secure supply chains, and deliver a product that the market increasingly demands.

16. Q&A (blog-style final section)

-

How quickly can my mill pivot to include insect protein?

A: With supplier audits and a 3-phase plan (lab → pilot → commercial), many mills can run initial trials within 2–3 months.

-

Will customers accept fish fed on insect-inclusive feed?

A: Increasingly yes — transparency, certifications, and marketing education accelerate acceptance.

-

Do I need a new extruder?

A: Not always. Many modern twin-screw extruders handle mixed raw materials; you may only need process optimization. Older single-screw lines may require upgrades for higher SME and better cook control.