As demand for nutritious and safe pet food continues to rise, more manufacturers are turning to Pet Food Extruder technology to stay ahead in the competitive pet food industry. Whether you’re running a large-scale production facility or exploring equipment upgrades, this guide explains why extrusion is a game-changer.

Why Use a Dog Food Extruder Machine?

Unlike traditional cooking methods, extrusion combines cooking, shaping, and sterilization in one efficient process. This modern approach enhances product quality, reduces waste, and supports consistent output. Below are key advantages of using Pet Food Processing Equipment in your production line.

1. Enhanced Nutritional Retention

Controlled temperatures and pressures during extrusion help preserve essential nutrients such as vitamins, amino acids, and fatty acids. Some extrusion technologies, including cold extrusion, are specifically designed to protect heat-sensitive ingredients.

2. Versatile Product Customization

Extruders offer flexibility in shaping kibble, creating treats, or producing semi-moist food. You can easily switch molds to create different sizes or textures to appeal to varying pet needs or breed types. This makes your Animal Food Processing Machine investment even more valuable.

3. Improved Digestibility and Food Safety

The extrusion process breaks down complex starches and proteins, making them easier for pets to digest. Moreover, the high temperatures kill harmful pathogens such as Salmonella and E. coli, ensuring your final product meets international food safety standards.

4. Increased Manufacturing Efficiency

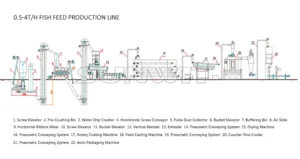

Extruders streamline production by combining multiple steps—mixing, cooking, shaping, and drying—into a continuous process. This reduces labor, minimizes downtime, and maximizes output. For example, our Pet Food Production Line can reduce energy consumption while maintaining high throughput.

5. Consistent Product Quality

Consistency is crucial in brand reputation and customer retention. With precise control over temperature, pressure, and moisture, an extruder ensures each batch maintains uniform size, shape, and density.

6. Cost-Effectiveness and Sustainability

By optimizing raw material usage and reducing food waste, extrusion not only saves costs but also supports sustainable practices. Many modern extruders are designed with energy efficiency and recyclability in mind, aligning with green production goals.

Common Questions About Dog Food Extrusion

1.Can a dog food extruder handle different recipes?

Yes. Advanced extruders are designed to switch between recipes with minimal changeover time, allowing you to respond to market demands quickly—whether you’re producing high-protein, grain-free, or functional pet foods.

2.Is extruded food better for dogs?

Extruded food can enhance digestibility, reduce allergic reactions, and improve nutrient absorption. When produced correctly, it supports better overall health in pets.

3.What is the ROI for investing in an extrusion system?

The return on investment can be substantial due to lower labor costs, higher efficiency, reduced waste, and consistent product quality. Partnering with a manufacturer like Zhuoheng® ensures long-term support and customization.

Why Choose Zhuoheng’s Pet Food Extrusion Solutions?

Our factory specializes in designing and manufacturing tailored extrusion solutions. From compact systems for startups to full-scale Pet Food Processing Equipment, we provide equipment that adapts to your production goals.

- Custom design based on your space and ingredient needs

- Energy-efficient motors and control systems

- Durable build for 24/7 operation

- On-site and remote technical support

Q&A Section

How long does a dog food extruder last?

With proper maintenance, industrial extruders can last 8–15 years, depending on usage and quality of materials.

Can I make hypoallergenic pet food with extrusion?

Absolutely. Extruders support customized recipes, including allergen-free formulas.

What types of ingredients can be processed?

From fresh meat and fish to grains, legumes, and vitamins—extruders handle a wide range of ingredients.

Is training provided with your machines?

Yes. Zhuoheng offers both on-site and virtual training to ensure smooth setup and operation.

What certifications do your machines comply with?

Our machines meet CE and ISO standards, and we offer customization based on export destination regulations.