There is a defining moment in every pasta maker’s journey. It’s when the romance of hand-rolling dough turns into the anxiety of fulfilling orders. Perhaps you started making fettuccine for friends, then a local deli asked for 5 kilos a week, and now a restaurant wants 50 kilos every Friday. You look at your kitchen counter, your hand-cranked roller, and your flour-dusted apron, and you realize: I cannot do this by hand anymore.

Welcome to the transition.

The global pasta market is a behemoth, valued at over $25 billion, but the real growth is happening in the “Premium” and “Fresh” segments. Customers are tired of industrial, dry supermarket pasta. They want the bite, the flavor, and the story of fresh, artisanal pasta.

Whether you are launching a homemade pasta business startup or you are a food processing manager looking to upgrade your facility’s output, this guide is your roadmap. At Zhuoheng, we have helped hundreds of businesses make this leap. We will move beyond the basics and dive deep into the economics, the equipment science, and the production secrets that separate the hobbyists from the professionals.

The Economics of Pasta – Costs, Margins, and Reality

Before we discuss torque and extrusion pressure, we must discuss profitability. Many newcomers underestimate the “hidden costs” of scaling.

The Three Tiers of Entry

Starting a pasta business isn’t one-size-fits-all. Based on our experience supplying factories and startups, here is the realistic financial landscape:

Home Micro-Business: Setup Cost: $800 – $1,500. Production: 2-3 kg/hour. Focus: Farmers Markets.

Small Commercial Workshop: Setup Cost: $15,000 – $40,000. Production: 10-30 kg/hour. Focus: Local Restaurants, Specialty Grocers.

Industrial Production Line: Setup Cost: $100,000+. Production: 100-500+ kg/hour. Focus: Supermarket Chains, Export.

The "Labor Trap" Calculation

Why invest in machinery? Let’s do the math. If you sell fresh pasta for $12/kg:

Hand Rolling: You produce 2kg/hour. Revenue = $24/hour. After ingredients and overhead, you are earning less than minimum wage.

Using Equipment: A Small Commercial Pasta Machine [Anchor Link to Pillar Page] produces 15kg/hour. Revenue = $180/hour. Your labor cost remains the same, but your profit margin explodes.

Industry Truth: In the food business, you don’t buy machinery to “make food.” You buy machinery to buy back your time.

The Science of Dough – Understanding Your Material

To choose the right pasta business equipment, you first need to understand what you are putting inside it. A machine is only as good as the dough it processes.

The "Hydration Ratio" Challenge

Home recipes often use a 60% hydration ratio (60g water/eggs to 100g flour). This is soft and easy to knead by hand. However, commercial pasta requires a much lower hydration ratio (usually 30-35%).

Why Drier is Better: Drier dough holds its shape better, has a longer shelf life, and dries faster.

The Problem: You cannot knead 32% hydration dough by hand. It is like trying to knead wet sand. It requires immense mechanical pressure to hydrate the semolina granules.

This is why upgrading to a powerful mixer and extruder from Zhuoheng is non-negotiable for commercial quality.

Phase One – The Artisan’s Foundation (Home & R&D)

If you are just testing the waters with a homemade pasta business startup, your focus is on recipe development and brand identity.

The Essential Hand Tool Checklist

Digital Scale: Baking is chemistry. There is no “pinch” of salt in manufacturing.

Brass Pasta Cutters: Why brass? Heavy brass wheels cut cleaner edges and seal filled pasta (like ravioli) better than cheap steel or plastic.

Wooden Drying Racks: Essential for air circulation.

Phase Two – The Commercial Upgrade (The "Make or Break" Stage)

This is the core of our guide. You have outgrown the KitchenAid attachment. You need a workhorse.

The Anchor of Your Business: The Extruder

For 90% of small to medium businesses, the most critical investment is a Small Commercial Pasta Machine. Unlike rollers that only make flat sheets, an extruder uses a screw (auger) to force dough through a metal plate (die).

Why You Need a Tabletop Pasta Extruder

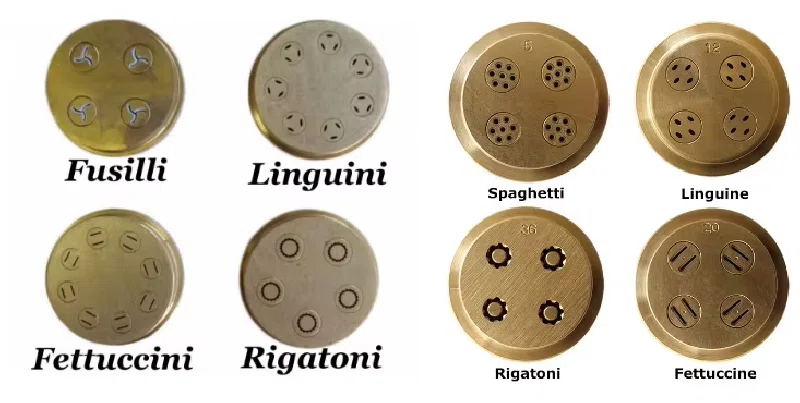

Versatility: One machine can make Spaghetti, Rigatoni, Fusilli, and Conchiglie just by changing the die.

Space Efficiency: These machines take up less than 1 meter of counter space but can churn out 50-100 restaurant portions an hour.

Consistency: The pressure ensures every noodle has the exact same thickness.

Deep Dive: Bronze vs. Teflon Dies (The Secret to Quality)

When you buy a Professional Pasta Machine for Small Business, you will be asked: “Do you want Bronze or Teflon dies?” Here is how Zhuoheng experts recommend you choose:

Bronze Dies (Traditional):

Result: Pasta with a rough, sandpaper-like surface.

Pro: Sauce clings to it beautifully. It screams “Artisanal.”

Con: Extrusion is slower; pasta looks paler/whiter.

Teflon Dies (Modern):

Result: Pasta is smooth, slick, and shiny yellow.

Pro: Stronger visual appeal in packaging; extrusion is faster.

Con: Sauce slides off easier.

Temperature Control: The Enemy is Heat

Friction creates heat. If your machine runs for 2 hours, the barrel gets hot. If the dough exceeds 45°C (113°F), the gluten structure breaks down, and the pasta becomes mushy. Our Recommendation: Look for a Heavy Duty Pasta Maker for Home or business that features a water-cooling jacket. This circulates cold water around the extrusion barrel, allowing you to run the machine 24/7 without compromising quality.

Phase Three – Industrial Automation (The Factory Floor)

When you are supplying supermarket chains, consistency is not enough—you need speed and hygiene certification. This is where Zhuoheng designs custom solutions for your factory.

1. Vacuum Mixing Technology

In our high-end Automatic Pasta Machine lines, we implement vacuum mixers.

The Concept: We suck the air out of the mixing chamber.

The Benefit: No air bubbles in the dough. The pasta comes out structurally denser, with a brighter yellow color (without artificial coloring) and a longer shelf life because oxidation is reduced.

2. Automated Ravioli & Filling Systems

Making ravioli by hand is romantic; making 5,000 ravioli by hand is a nightmare. Industrial forming machines connect directly to the food extruder Equipment. They inject a precise amount of filling (soft cheese, meat, vegetables) and seal the dough instantly.

3. The Science of Shelf Life: Pasteurization & Drying

This is the biggest hurdle for a growing pasta business equipment setup.

Fresh Pasta (Refrigerated): Needs to be pasteurized (steam treated) at 90°C+ to kill bacteria, then immediately cooled. This extends shelf life from 3 days to 45 days.

Dry Pasta (Shelf Stable): Requires a Static Dryer or Tunnel Dryer. You must slowly reduce moisture from 30% to 12.5%. If you dry too fast, the pasta cracks. If you dry too slow, it molds.

Troubleshooting Guide – Expert Solutions

Problem 1: White spots on the fresh pasta.

Cause: The flour wasn’t hydrated properly.

Solution: Your mixing time is too short, or your semolina is too coarse. Increase mixing time by 5 minutes.

Problem 2: Pasta is curving or curling as it exits the extruder.

Cause: Uneven speed of the knife or uneven temperature in the die.

Solution: Check if the fan blowing on the pasta is too strong on one side. Clean the die holes—a blocked hole causes uneven pressure.

Problem 3: The pasta falls apart when cooked.

Cause: “Thermal Stress” or low gluten development.

Solution: The dough got too hot during extrusion. Ensure your water-cooling system is active.

Marketing Your Product & Conclusion

You have the best Small Pasta Maker, and your product is perfect. How do you sell it? Use your investment in industrial equipment as a selling point: “We use Zhuoheng water-cooled extrusion to ensure perfect al dente texture every single time.”

Starting a pasta business is a journey of passion, but scaling it is a journey of engineering. Whether you are looking for a compact unit to start your boutique shop, or a fully automated 500kg/h production line, the equipment you choose will define your product.

At Zhuoheng, we don’t just sell machines; we provide the technical know-how to ensure your transition from “Homemade” to “Professional” is seamless.

Frequently Asked Questions (FAQ)

-

What is the difference between a pasta extruder and a sheeter?

A: A pasta extruder forces dough through a mold to create shapes like macaroni, penne, and spaghetti. It is excellent for consistency and speed. A sheeter (roller) flattens dough into sheets, which are then cut into ribbons (fettuccine, tagliatelle). Extruders are generally more versatile for scaling businesses.

-

Can I use a Small Commercial Pasta Machine for gluten-free pasta?

A: Yes! In fact, extrusion is the best method for gluten-free pasta. Since GF dough lacks the elasticity of wheat gluten, it is very hard to roll by hand. An extruder uses high pressure to compress rice, corn, or chickpea flour into a solid shape. However, ensure your machine has a powerful motor (high torque) to handle the denser GF dough.

-

How long does fresh pasta last?

A: Standard fresh pasta lasts 2-3 days in the fridge. If you use a professional pasteurizer (heat treatment), you can extend this to 30-45 days. If you use Modified Atmosphere Packaging (MAP) along with refrigeration, you can achieve 60+ days shelf life without freezing.

-

What flour is best for commercial pasta making?

A: For extruded pasta, 100% Durum Wheat Semolina is the gold standard. It is high in protein and holds its shape under boiling water. For rolled pasta, a mix of "00" soft wheat flour and semolina (plus eggs) is often used for a more delicate texture.