In the high-stakes environment of industrial food production, your equipment is more than just a tool—it is the heart of your operation. Whether you are running a high-end trattoria or a small-scale production facility, the cleanliness of your pasta-making equipment directly dictates the quality of your product, the safety of your customers, and the lifespan of your investment.

As a dedicated manufacturer of food processing production lines, we have seen firsthand how improper maintenance can turn a high-performance Small Commercial Pasta Machine into a liability. Starch buildup, bacterial growth in interstitial spaces, and oxidative corrosion are the silent enemies of efficiency. In this comprehensive guide, we will break down the science and methodology of cleaning and sanitizing your equipment, drawing on industry standards, mechanical engineering principles, and operational best practices.

The Material Science: Why Your Machine Reacts to Cleaning

To clean a commercial pasta machine for restaurant use effectively, you must first understand what it is made of. Most competitors treat all metals the same, but as a manufacturer, we know that chemical reactions can ruin a machine faster than dough buildup.

SUS304 Stainless Steel vs. Aluminum Alloys

Most high-end Automatic Pasta Machine units utilize SUS304 stainless steel for food-contact zones.

The Advantage: It is non-reactive and resists organic acids found in fermented doughs.

The Cleaning Logic: You can use slightly more acidic sanitizers (like vinegar solutions) without risking “pitting” corrosion.

However, many internal components or tabletop frames use Anodized Aluminum.

The Risk: If you use a high-alkaline dishwasher detergent on aluminum, it will undergo a process called “blackening” or oxidation. This destroys the smooth surface tension, making dough stick more aggressively in the future.

Our Solution: At Zhuoheng, we prioritize SUS304 for all “wet” zones to ensure that your Professional Pasta Machine for Small Business remains inert and easy to sanitize regardless of the cleaning agent used.

The Role of Surface Roughness (Ra Value)

In engineering, we measure surface smoothness as the “Ra value.” The smoother the metal, the fewer “anchor points” there are for bacteria like Salmonella to attach.

Pro Tip: If you use a metal scraper and scratch the rollers, you are effectively increasing the Ra value, creating microscopic “caves” where starch can rot. Always stick to the nylon brushes provided with your Small Pasta Maker.

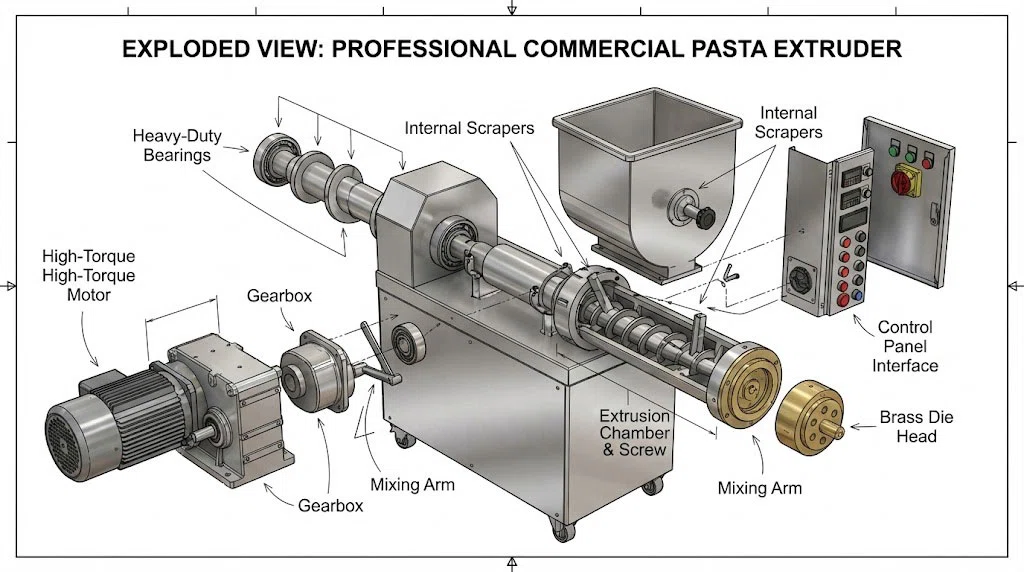

The Anatomy of a Clog: Where Bacteria Hide

A restaurant pasta extruder is a complex assembly of pressure and friction. Cleaning the outside is only 10% of the job. To truly surpass hygiene standards, you must target the “Dead Zones.”

The Scraper Gap

Behind every roller is a scraper blade. Its job is to peel the dough sheet off the roller. However, fine flour dust can bypass the blade and settle in the gap between the scraper and the housing. Over time, this dust absorbs ambient moisture and creates a “fermentation pocket.”

The Bearing Housings

In a Heavy Duty Pasta Maker for Home or small business, the points where the rollers meet the frame are the most vulnerable. If liquid sanitizer seeps into these bearings, it washes away the internal grease, leading to “metal-on-metal” shrieking and eventual motor burnout.

Industrial Pre-Cleaning Protocol (SOP)

Before a single drop of water touches the machine, you must follow a Standard Operating Procedure (SOP) that aligns with global safety standards.

Lock-Out/Tag-Out (LOTO)

For any Semi-Automatic Noodle Machine, simply turning off the switch is not enough.

Disconnect: Physically unplug the unit.

Verify: Press the “On” button once more to ensure no residual energy is stored in the capacitors.

Secure: In a factory setting, the plug should be placed in a lockout box to prevent accidental activation.

The "Dry State" Assessment

The biggest mistake in cleaning a commercial pasta machine for restaurant is adding water too early.

Starch + Water = Glue. * Starch + Air = Dust. You want to deal with dust, not glue. Allow the machine to sit for 30 minutes after production to allow the gluten structure to relax.

Stage 1: The Dry Extraction Method

This is where we move beyond the advice of competitor websites. We recommend a “Top-Down” dry extraction.

Specialized Tooling

Instead of a kitchen sponge, professional operators should use:

Nylon Detailing Brushes: Different stiffness levels for the rollers vs. the exterior.

Vacuum with HEPA Filter: Do not blow the flour dust into the air; suck it out of the crevices.

Wooden Probes: Use bamboo skewers to gently pick out dough from the Tabletop Pasta Extruder.

The Sacrificial Dough Cycle (The "Magnet" Technique)

If you are running a high-volume Professional Pasta Machine for Small Business, you cannot afford to disassemble it every two hours.

Take a 200g piece of “Cleaning Dough” (Recipe: 70% flour, 30% water).

Run this dough through the widest setting, then the narrowest.

The stiff dough acts as a physical “magnet,” grabbing stray particles or metallic fines.

Precision Disassembly: The Core of Industrial Sanitation

For a high-performance Small Commercial Pasta Machine, wiping the visible surfaces is merely the beginning.

Maintaining the Combs and Scrapers

In any Professional Pasta Machine for Small Business, the rollers are equipped with “combs.”

The Disassembly: Using the specialized tools, gently loosen the retaining bolts.

The Deep Soak: Soak these combs in warm, soapy water for 5 minutes. Use a soft-bristled brush to clean between the teeth.

Factory Insight: We recommend checking the alignment of these scrapers every 500 operating hours to prevent uneven thickness and motor strain.

The Auger and Extrusion Chamber

For a commercial pasta machine for restaurant that utilizes an extrusion system, the auger is the heart of the pressure system.

Residual Pressure Release: Run the machine for 5 seconds without adding new dough to clear the chamber.

Axial Extraction: Pull the auger out along its axis. If the auger is stuck, never use a hammer. Apply food-grade lubricant and wait for 10 minutes.

Specialized Die Head Cleaning

The die heads are the most delicate part of your restaurant pasta extruder. Any microscopic blockage will cause jagged edges on your pasta.

The "Freezer Extraction" Method

At our factory, we recommend this over aggressive scrubbing:

Place the used die in a freezer for 20 minutes. The moisture in the dough shrinks, detaching it from the metal walls. A gentle tap will cause the residue to fall out in one solid piece.

Ultrasonic Cleaning for Industrial Efficiency

If you are operating a large-scale processing plant, we recommend an ultrasonic cleaner. Submerging your dies in a heated ultrasonic bath removes micron-level residues, ensuring a professional, high-gloss finish for your pasta.

The Zhuoheng Solution: Engineering for "Zero-Downtime"

At Zhuoheng, we engineer every Small Commercial Pasta Machine with “ease of cleaning” as a core feature.

Patented Quick-Release System

Our Semi-Automatic Noodle Machine features a tool-less disassembly system. Flip two lateral pressure locks, and the entire roller assembly can be removed in under 10 seconds.

The Business Impact: This reduces daily cleaning time by 45 minutes, saving you hundreds of labor hours annually.

Seamless Welding and IP65-Rated Motors

We utilize robotic seamless welding to eliminate “bio-dead zones.” Additionally, our motors are sealed to IP65 standards, preventing flour dust from entering the gearbox and extending the machine’s lubrication cycle by 60%.

The Science of Lubrication: The Lifeblood of Your Machinery

Once cleaning is complete, you must lubricate your machine before the next start-up. Failure to do so will lead to “shrieking” friction.

The Rule of Food-Grade Mineral Oil

Why Mineral Oil? It is tasteless, odorless, and does not oxidize. Vegetable oils (olive, sunflower) will turn rancid and sticky, eventually seizing the internal gears.

Warning: Never use industrial greases like WD-40. They contain chemical propellants that are toxic. Always ensure your lubricant is NSF-H1 certified.

Troubleshooting: Managing Technical Challenges

As a factory supporting thousands of commercial pasta machine for restaurant owners, we have identified key issues:

The "Grey Streak" Mystery

The Cause: Microscopic metal fines or oxidized lubricant from the lateral bushings.

The Fix: Check the Scraper Tension. If it’s too tight, it’s grinding the rollers. Adjust and run a high-fat “purge dough.”

Rust Remediation

If your Professional Pasta Machine for Small Business shows orange spots:

The Fix: Use a paste of baking soda or a fine-grit (1000+) polishing pad with mineral oil. Never use steel wool, as it leaves behind carbon particles that accelerate rusting.

Creating a Culture of Hygiene: Training Your Team

Managing a Small Pasta Maker in a high-turnover kitchen requires a systematic training approach.

The Cleaning Log: Maintain a logbook where staff sign off on daily sanitization.

Visual Standards: Post a laminated “Standard Photo” of a perfectly cleaned machine next to the workstation.

Comprehensive FAQ: Expert Answers

-

Can I use steam to clean my restaurant pasta extruder?

Use steam only on detached stainless steel die heads. Never steam the main housing as it can penetrate bearing seals.

-

My die heads are tarnishing (turning brown). Is this dangerous?

A light brown patina on bronze dies is normal. However, if you see green residue, it means the die was left wet and must be cleaned with citric acid immediately.

-

How often should I replace the internal scrapers?

For a Professional Pasta Machine for Small Business, we recommend replacement every 12-18 months to ensure they remain effective at peeling dough.