The journey of food processing machines spans thousands of years. From ancient methods of food preservation to today’s automated lines, this evolution tells a story of necessity, innovation, and global impact. In this post, we’ll walk through the complete historical development of food processing technologies, explore major milestones, and connect them to modern industry needs—especially for manufacturers and global food exporters.

From Fire and Fermentation to the First Machines

Our ancestors used primitive techniques like sun-drying, smoking, fermenting, and salting to extend food shelf life. These early “processing” methods were key for survival. Some of these traditions, like fermentation, still thrive today in artisanal and industrial applications.

The Spark of Innovation: The 19th Century Revolution

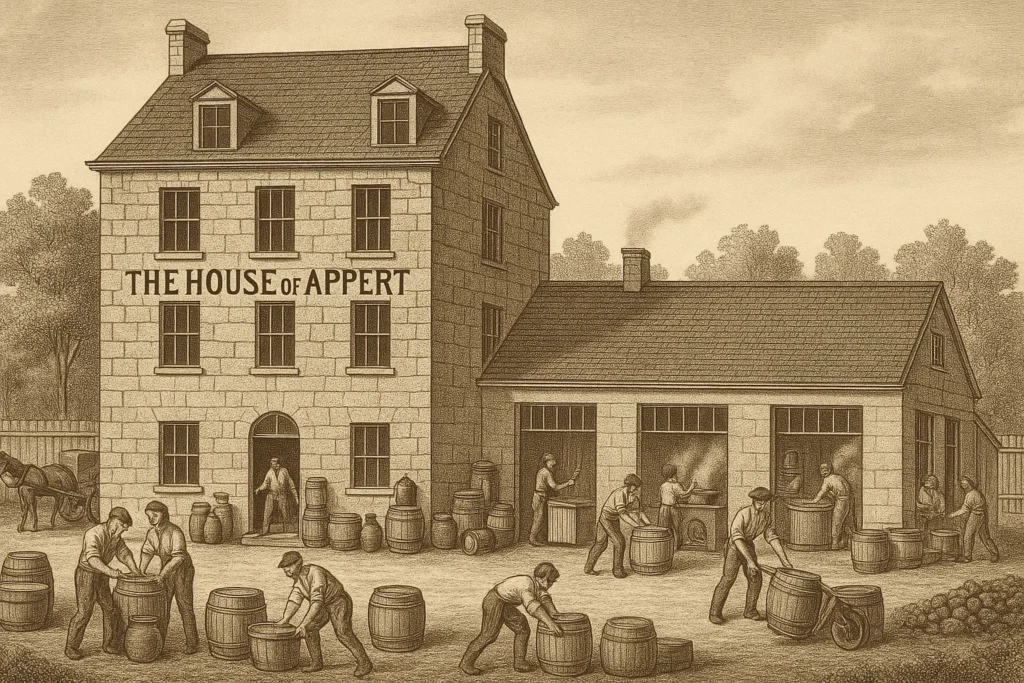

Until the early 1800s, little changed in food preservation. Then came Napoleon Bonaparte. In 1795, he famously offered a reward to anyone who could invent a method for long-term food storage for his armies. French confectioner Nicholas Appert won the prize by sealing cooked food in glass jars—a method that laid the groundwork for canning.

Soon after, British merchant Peter Durand patented the first tin can, and the food preservation race was on. This milestone marked the birth of commercial-scale food processing machines.

Industrialization and Military Influence

The 20th century saw food processing leap forward, driven by two World Wars and the space race. New technologies like spray drying, vacuum sealing, and freeze-drying were born from military necessity. Products like powdered eggs, Spam, and canned rations became global staples.

Postwar Boom and the Convenience Revolution

After WWII, Western societies embraced convenience. Supermarkets, frozen “TV dinners,” microwaves, and ready-to-eat meals surged in popularity. Processors began prioritizing not only preservation but taste, speed, and marketing appeal. This era also saw the rise of major brands that still dominate the global food scene today.

The Rise of Automation: Food Machinery in the Late 20th Century

By the 1980s and 1990s, food processing was increasingly automated. Conveyor systems, high-speed mixers, and programmable control units turned small-batch production into streamlined industrial workflows. In parallel, global food demand began rising, especially for safe and hygienic processed foods for export.

It’s in this backdrop that manufacturers like Zhuoheng emerged, delivering tailored food extruder systems that could support mass production while ensuring quality and safety compliance.

Where Are We Now? Smart Factories and Sustainable Solutions

In recent years, the food industry has entered a new chapter: smart processing. AI, robotics, IoT sensors, and blockchain tracking are now being integrated into food processing machines to ensure traceability, energy efficiency, and adaptive control. This is particularly important for export-driven manufacturers navigating stringent international safety standards.

Modern machines are also being tailored for alternative proteins, low-calorie snacks, gluten-free products, and pet foods—products where precision extrusion is key. That’s why choosing the right food extruder system is critical for scaling with flexibility and confidence.

Conclusion: Why It Matters

Understanding the history of food processing is more than academic—it informs the future. Every step, from drying meat in the sun to high-efficiency food extruder lines, represents a shift in how we feed the world.

For manufacturers and exporters, investing in efficient, customized food processing solutions isn’t just smart—it’s essential. Companies like Zhuoheng continue to push the industry forward by designing systems that merge tradition with technology.

Q&A: Common Questions About Food Processing Machines

Q:When were food processing machines invented?

The first recognizable food processing machines were invented in the early 19th century. Nicolas Appert developed the bottling method in 1809, followed by the tin can in 1810.

Q:What is the difference between primary, secondary, and tertiary food processing?

Primary involves raw ingredients (e.g., milling grain), secondary refers to turning ingredients into food (e.g., baking bread), and tertiary is mass-produced, ready-to-eat food (e.g., frozen meals).

Q:Why are modern food processing machines important for exporters?

They ensure hygienic standards, reduce waste, improve shelf life, and enable scalable production for global markets—especially with international safety compliance.

Q:What’s the role of a food extruder today?

Food extruders are vital for shaping, cooking, and texturizing food products like snacks, cereals, and pet foods. They enable continuous, high-output production with customization.