For exporters and processing factories, flexibility is no longer a luxury—it is a competitive edge. The common question we hear is: Can one Pet Food Production Line handle dry kibble, wet canned food, and even treats? The answer is nuanced. Yes, it’s possible with modular systems and proper planning, but each type of pet food has unique requirements that cannot be ignored.

Breaking Down the Core Differences

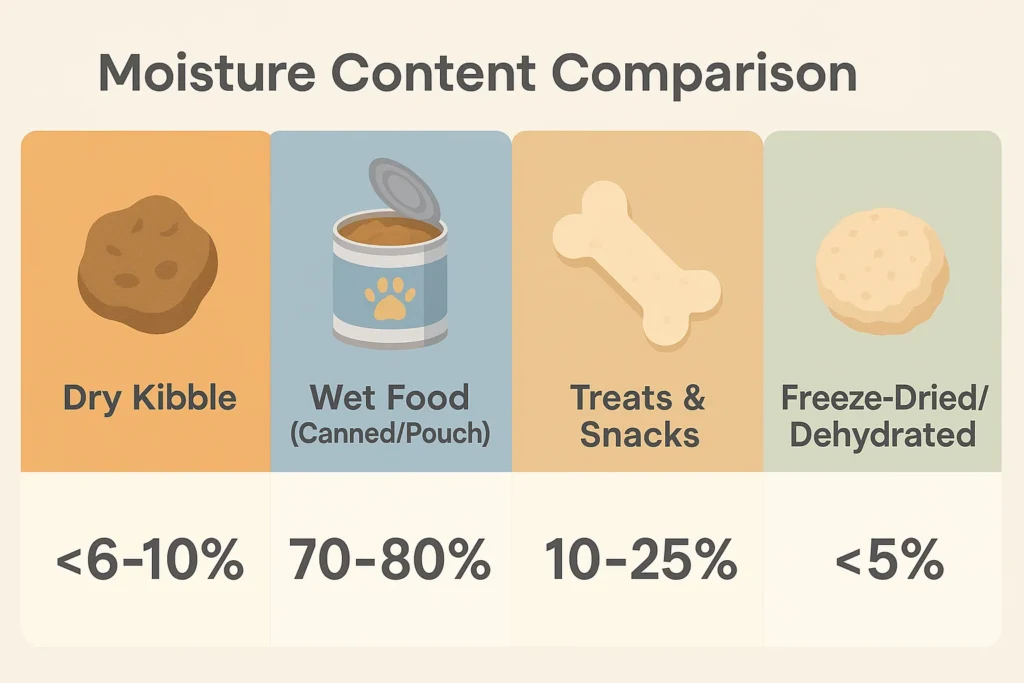

Each pet food category requires its own process and equipment. Attempting to run them all on the same line without preparation can lead to inefficiencies, quality issues, and even safety concerns. Here is a simplified breakdown:

| Pet Food Type | Moisture Content (%) | Core Equipment | Complexity | Hygiene Level |

|---|---|---|---|---|

| Dry Kibble | 6–10% | Extruder, Dryer, Coater | Medium | Moderate |

| Wet Food (Canned/Pouch) | 70–80% | Cooker, Retort Sterilizer, Filler | High | High |

| Treats & Snacks | 10–25% | Baking Oven, Molding Machine | Medium | Moderate |

| Freeze-Dried/Dehydrated | <5% | Freeze-Dryer, Dehydrator | High | High |

Challenges of Multi-Product Manufacturing

Running different food types on one Animal Food Processing Machine presents unique challenges:

- Cross-Contamination Risk: Switching from meat-heavy wet food to grain-based kibble requires deep cleaning to meet food safety regulations (HACCP/GMP).

- Switching Downtime: Every product change means lost production time. Facilities must calculate whether flexibility offsets the downtime cost.

- Energy Consumption: Retort sterilizers for wet food consume significantly more energy than kibble extrusion. This impacts operational costs.

- Consistency Control: Maintaining uniform taste, texture, and nutritional balance across multiple recipes is complex without automation.

Modular Solutions for Flexible Production

Modern technology has brought forward modular systems that make multi-product manufacturing more achievable. Our custom-built Pet Food Extruder solutions allow interchangeable dies and molds, automated recipe adjustments, and quick sanitation systems. This means you can switch from dog kibble in the morning to cat treats in the afternoon with minimal downtime.

Best Practices for Success

Design facility layout with separate dry and wet food zones.

Implement automated dosing for consistent nutrition.

Adopt CIP (Clean-in-Place) systems to minimize downtime.

Market Trends: Why Flexibility Matters

According to industry data, global pet food exports exceeded USD 100 billion in 2024, with Pet Food Processing Equipment demand rising fastest in Asia and South America. Consumer preferences are shifting toward grain-free, hypoallergenic, and functional diets, which means factories must adapt quickly to new formulations. Exporters who can offer multiple product formats win contracts faster.

ROI Considerations for Factories

Investing in flexible production lines is not just about capability—it’s about return on investment (ROI). Small-scale exporters may prioritize adaptability, while large-scale manufacturers usually build dedicated lines for efficiency. A hybrid approach often works best: one modular line for niche or specialty products, and separate lines for high-volume kibble.

Case Study: How Customization Delivers Results

A South American client approached us wanting to produce both dry dog food and semi-moist training treats. With a customized Animal Food Processing Machine and modular molds, we delivered a line that allowed them to switch products within three hours. Their export orders doubled within the first year, proving that flexibility can be profitable when executed correctly.

Conclusion

A single Pet Food Production Line can indeed produce multiple pet food categories, but only if designed with modularity, automation, and sanitation in mind. Exporters and processing companies who embrace flexible systems are better positioned to meet fast-changing consumer trends and win in competitive global markets.

At Zhuoheng, we specialize in building customized Pet Food Extruder systems with modular designs, CIP cleaning, and automation features that help you scale efficiently. Whether you aim to expand into wet food, diversify with treats, or explore specialty diets, our team of engineers will guide you from design to installation.

Q&A Section

Can one line make both dog and cat food?

Yes, modular extruders allow recipe adjustments for different animals. Dies and molds can be swapped to match size and texture requirements.

How do I avoid cross-contamination?

Install CIP cleaning systems and separate storage for meat vs grain ingredients. Following HACCP standards ensures safety.

Is a multi-product line worth the cost?

For medium exporters, yes. Modular Pet Food Processing Equipment offers flexibility without building multiple facilities. Large manufacturers often mix modular and dedicated lines.

What about freeze-dried or raw diets?

These require specialized systems (freeze-dryers, cold storage), but modular setups can integrate them alongside traditional extrusion lines.

Where can I learn more?

Visit our Pet Food Production Line page for tailored solutions and case studies.