In today’s global market, pet food manufacturers—from agile exporters to multinational brands—are adopting automation to deliver consistent quality, robust safety, and competitive costs. This comprehensive guide blends fundamentals with measurable benchmarks (OEE, energy, changeover), compliance frameworks (HACCP, ISO, AAFCO/FEDIAF), and practical ROI to answer one question: how automated can a factory truly become?

What “Full Automation” Really Means

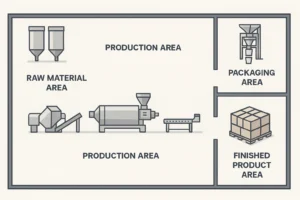

A modern line can automate nearly every task—raw material receiving and batching, mixing, extrusion and cooking, drying, coating, packaging, palletizing, in-line inspection, and even internal logistics via AGVs. Operators remain essential for recipe governance, sanitation validation, preventive maintenance, and audit readiness. In practice, “full automation” means humans supervise and optimize, while machines execute with precision.

Key Areas of Automation (From Basics to Advanced)

Ingredient Handling & Mixing

Automated silos and smart dosing keep vitamins, proteins, and palatants within ±0.5% targets. Batching logs are tied to ERP/MES for lot traceability. With Zhuoheng’s customized Animal Food Processing Machine, storage, weighing, and mixing run as one synchronized workflow.

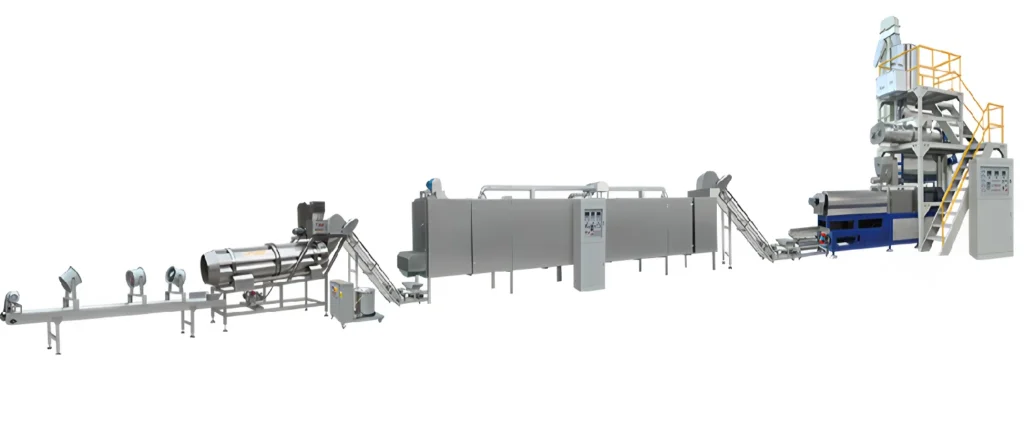

Extrusion & Cooking

The extruder is the heart. Closed-loop controls hold temperature within ±1 °C and screw speed within 5 RPM steps. Result: consistent expansion ratio (±3%), texture uniformity (<5% hardness variance), and reliable kill-step lethality for food safety. With Pet Food Extruder tooling, shape changes take <15 minutes.

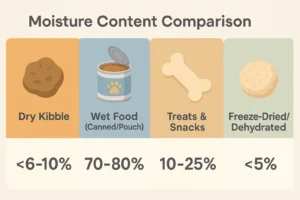

Drying & Coating

Multilayer dryers drive moisture to 8–10%, extending shelf life without scorched notes. Vacuum or drum coating applies oils, slurries, and micronutrients uniformly, improving palatability while preserving heat-sensitive vitamins.

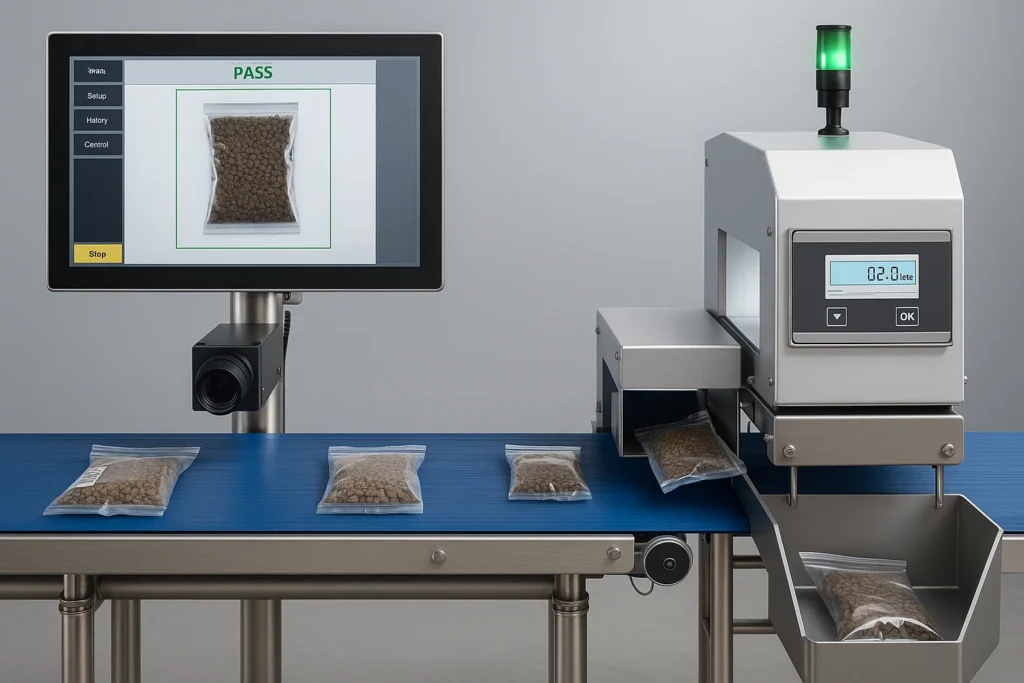

Packaging, Palletizing & In-line Inspection

High-speed fillers and sealers handle pouches, cans, and trays; robots manage case packing and palletizing. Vision systems verify label/OCR; X-ray/metal detectors reject contaminants. Our modular Pet Food Processing Equipment links seamlessly with end-of-line quality gates.

Smart Logistics (AGVs)

AGVs shuttle raw materials and finished pallets, eliminating forklift bottlenecks and lowering incident risk—critical for hygiene zoning and audit trails.

Compliance & Food Safety (HACCP | ISO | AAFCO/FEDIAF)

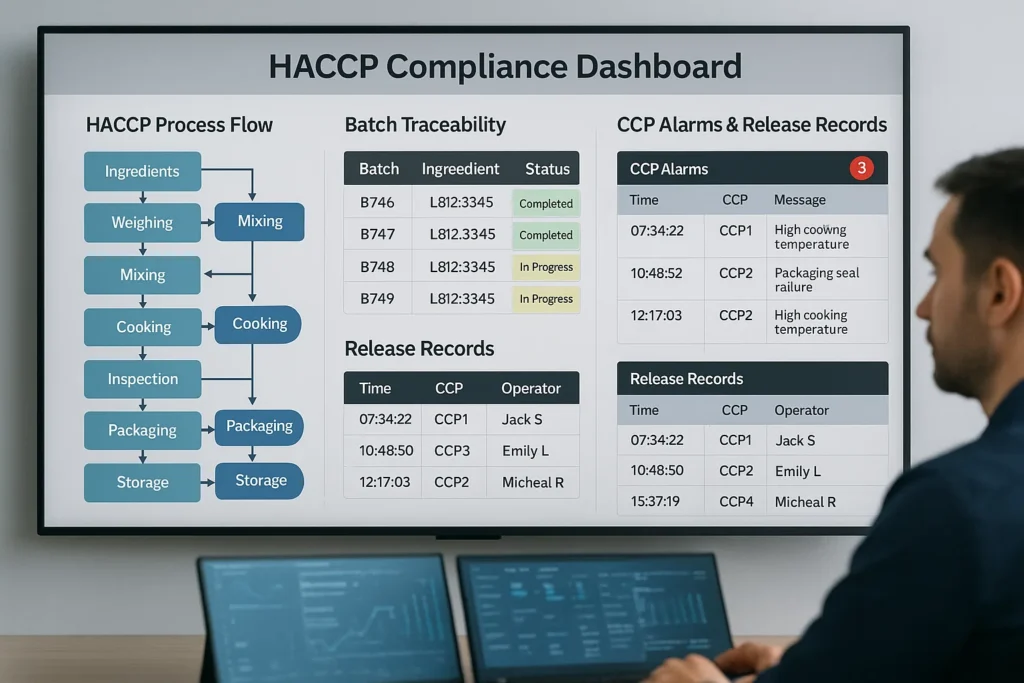

A properly integrated line aligns with HACCP and GMP, and can be certified against ISO 9001/22000, CE/UL/CSA. Nutritional compliance follows AAFCO (NA) and FEDIAF (EU). ERP/MES integrations log suppliers, CCP/OPRP checks, sanitation records, and lab results—ready for retailer audits.

Measurable Gains: Benchmarks & ROI

Typical results reported by plants after automation upgrades:

• OEE: 85–92% (vs 65–70% semi-auto)

• Energy: 15–20% reduction via smart heating/drying control

• Waste: <1% thanks to precision feeding and feedback loops

• Changeover: <15 minutes with auto die recognition

• Labor: 60% fewer operators per shift

• Output: +18–22% annualized through reduced downtime

Semi-Auto vs Full-Auto (Side-by-Side)

| Feature | Semi-Auto Line | Fully Automated Line |

|---|---|---|

| Labor/Shift | 12–15 operators | 4–6 operators |

| OEE | 65–70% | 85–92% |

| Changeover | 2–3 hours | <15 minutes |

| Energy | Baseline | 15–20% lower |

| Waste | 5–7% | <1% |

| ROI Payback | 4–6 years | 18–24 months |

[note] Our standardized, modular design trims spare-parts inventory by ~30% and shortens maintenance windows—fewer surprises, faster uptime.

Customization & Product Innovation

With quick-change tooling, one line can produce 50+ SKUs: pellets, sticks, hollow shapes, and co-extruded treats (crunchy shell + soft core). Texture and density profiles are tuned for puppy/senior formulas, aquatic floating/sinking feeds, or hypoallergenic diets.

The Role of AI & IoT (From Monitoring to Prediction)

• Predictive maintenance: model-based wear prediction accurate to ~90%, cutting unplanned stops.

• IoT sensors: continuous signals for temperature, humidity, vibration; water content held within ±0.5%.

• Vision + OCR: detects shape defects, seal integrity, and label compliance—bad packs auto-rejected.

• Cloud diagnostics: remote dashboards accelerate troubleshooting and operator training.

Real-World Buyer Questions (And Straight Answers)

Does full automation remove the need for people?

No. People shift from repetitive handling to higher-value roles: recipe governance, sanitation validation, data review, and continuous improvement.

Can we upgrade step-by-step?

Yes—most clients start with end-of-line packaging and inspection, then automate batching/extrusion, and finally integrate ERP/MES for full traceability.

Typical delivery & on-site schedule

Manufacture: 45–60 days; on-site install & training: 10–15 days. Trade terms: FOB, EXW, CIF are supported. Documentation available in English.

Why Zhuoheng (Turnkey, Scalable, Compliant)

• Turnkey projects with English SOPs and training

• Modular scaling from entry to fully automated systems

• Compliance-ready documentation (HACCP/ISO/CE/UL/CSA)

• Remote diagnostics and predictive maintenance

• Proven upgrades for Pet Food Extruder lines and integrated end-of-line quality gates

CTA] Explore Our Pet Food Production Line Solutions → https://zhuohengextruder.com/Extruder-Machine/pet-food-production-line/

Conclusion

How automated can a Pet Food Production Line be? From batching to palletizing, nearly every stage can be automated with tight controls, hygiene zoning, and data-driven traceability. For manufacturers, that means higher efficiency, safer operations, faster ROI, and flexible innovation across 50+ SKUs. With Zhuoheng’s integrated extrusion and process solutions, moving from semi-auto to full automation is a confident, step-wise journey.

Q&A (Buyer-Focused FAQ)

Is full automation affordable for small/medium plants?

Yes. Start with semi-auto packaging/inspection, then add automated batching/extrusion. Modular upgrades reduce upfront CAPEX while accelerating ROI (often 18–24 months).

How does automation improve food safety?

Fewer manual touches reduce contamination risk. CCP/OPRP checks, sanitation logs, and vision/X-ray/metal detection provide audit-ready evidence.

Can one line make multiple product types?

Yes—quick-change dies enable pellets, sticks, hollow/co-extruded treats, and aquatic feeds (floating/sinking) with <15-minute changeovers.

What documentation is available for exports?

English SOPs, training manuals, FAT/SAT protocols, and compliance packs (HACCP/ISO/CE/UL/CSA). Trade terms: FOB/EXW/CIF.

What typical savings should we expect?

Benchmarks show 15–20% energy reduction, <1% waste, 60% lower staffing per shift, and OEE at 85–92%—driving faster ROI and higher annual output (+18–22%).