The global appetite for pet food keeps climbing as pets become true family members. For manufacturers and international buyers, setting up a Pet Food Production Line is a high-return but highly technical project. This guide walks you through equipment choices, layout, food safety, specification benchmarks, regulations, and FAQs—so you can plan confidently and launch faster.

Core Equipment by Product Type

Your exact equipment stack depends on product type—dry kibble, wet food, or treats—and your capacity targets.

Dry Pet Food (Kibble)

- Mixers — ribbon/paddle/batch types for uniform blending of grains, proteins, vitamins, and minerals.

- Grinders — create consistent particle size to stabilize texture and digestibility.

- Pet Food Extruder — cooks and shapes the dough under heat and pressure; controls density and expansion.

- Dryers — remove moisture for shelf stability; consider energy-saving multi-pass designs.

- Cooling Systems — prevent condensation and fat migration before packaging.

- Packaging Machines — automatic weighing, sealing, and labeling for speed and accuracy.

Wet Pet Food (Canned/Pouch)

- Cookers — batch or continuous cooking of meat, vegetables, and grains.

- Filling Machines — for cans, pouches, or trays with precise dosing.

- Sterilization — retorts or HPP to meet shelf-life and safety requirements.

Pet Treats & Specialty Snacks

- Molders/Coaters — shape treats; apply gravy or seasonings.

- Enrobers — uniform coating for flavor and appearance.

Zhuoheng offers turnkey lines spanning compact systems to high-capacity Pet Food Processing Equipment. Systems are tailored to your formulas, throughput, and budget.

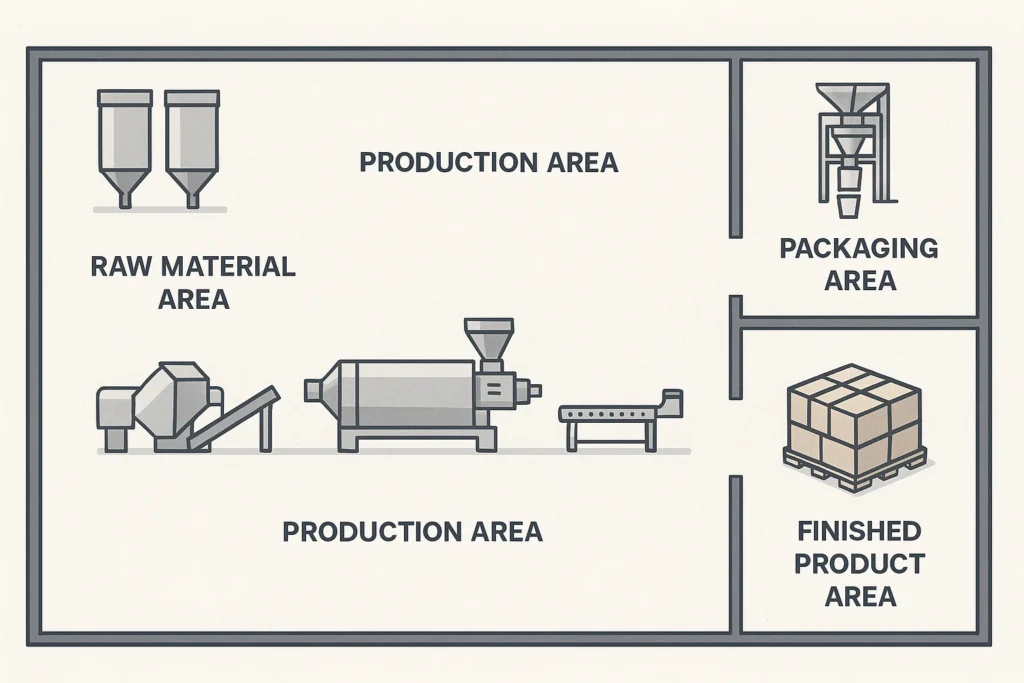

Facility Layout and Hygienic Design

Plan a linear flow: receiving → storage → mixing/grinding → cooking/extruding → drying/cooling → packaging → finished-goods storage. Separate raw and finished zones, enable one-way personnel and material movement, and specify easy-to-clean stainless contact surfaces.

Purchase Considerations for Animal Food Processing Machine Systems

- Capacity & Scalability — modular lines that expand with demand.

- Certifications — CE, ISO, HACCP for export markets.

- Automation — better consistency, lower labor costs, easier compliance.

- Service — global parts, remote diagnostics, onsite commissioning.

Quality Control and Food Safety

Embed checkpoints for moisture, texture, bulk density, and nutrient targets. Implement GMP and HACCP, sanitation SOPs, environmental controls (air, temperature, humidity), metal detection, and full lot traceability.

Future Trends in Pet Food Processing Equipment

- IoT dashboards for OEE, energy, and quality metrics.

- Short-run personalization: quick die changes, recipe libraries.

- Sustainability: low-energy dryers, heat recovery, eco-packaging.

Case Study: Mid-Sized Export Factory Upgrade

A mid-sized Asian producer upgraded to a fully automated line centered on a Pet Food Extruder plus integrated cooling and auto-packaging. Output rose ~40%, labor dropped ~30%, and consistency improved, enabling entry into EU retailers.

Equipment Model & Specification Comparison

Match your targets with the machine’s capabilities. Below are representative extruder models supplied by Zhuoheng:

| Model | Capacity (kg/h) | Power (kW) | Application | Key Features | |

|---|---|---|---|---|---|

| ZH-65 | 100–150 | 22 | Small dry pet food / aquatic feed | Compact footprint, low energy | |

| ZH-70 | 200–300 | 37 | Mid-sized kibble lines | Enhanced mixing & cook profile | |

| ZH-85 | 500–800 | 75 | Large-scale Pet Food Production Line | High throughput, advanced controls | |

| ZH-95 | 1000–1500 | 110 | Industrial animal feed plants | Multi-recipe, IoT integration |

Industry Standards & Regulatory Compliance

For export markets, align production on your Animal Food Processing Machine with key frameworks: EU Regulation (EC) No 767/2009 (feed rules), AAFCO guidelines (labeling & ingredients, North America), ISO 22000 & HACCP (food safety), and China GB/T 13078 (feed hygiene). Meeting these accelerates customs clearance and strengthens buyer trust.

FAQ – Common Questions from Buyers

How much space is required?

Small lines fit in 300–500 m²; high-capacity facilities often need 1,500 m²+ with raw/pack/warehouse separated.

What’s the typical investment?

~US$50k for compact setups to US$500k+ for fully automated, high-throughput lines.

Can one line handle both wet and dry?

Possible but not efficient; dedicated lines are recommended for quality and changeover time.

How many operators per shift?

Highly automated lines may run with 3–5 operators per shift plus QC and maintenance support.

What about energy consumption?

Key drivers are extruder motors and dryers. Energy-saving dryers and heat recovery significantly reduce OPEX.

How do I ensure food safety?

GMP/HACCP, sanitation SOPs, validated kill steps, metal detection, allergen control, and full traceability.

Lead time & installation?

Typical lead time 45–90 days depending on customization; onsite commissioning and operator training included.

Can I scale up later?

Yes—choose modular systems with spare utility capacity (power, steam, air) for future add-ons.

Do you provide recipes and die sets?

Zhuoheng provides starter recipes, die libraries, and training for different kibble shapes and densities.

Documentation for export compliance?

Full CE/ISO documentation, FAT/SAT reports, operator manuals, and maintenance schedules are provided.

Conclusion & Recommendation

Selecting the right Pet Food Production Line is less about buying machines and more about engineering repeatable quality, safety, and scale. Zhuoheng delivers configurable, export-ready solutions—from pilot systems to multi-ton per hour plants—built around Pet Food Processing Equipment and supported by global training and service. If you plan to diversify, our commercial Fried Snack Food Production Line leverages similar extrusion and drying know-how, helping you extend your product portfolio with minimal learning curve.