Food Processing Equipment

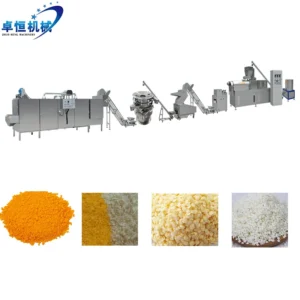

Our Food Processing Equipment is designed to meet the demands of the food manufacturing industry, offering high-quality solutions for processing snack foods, cereals, pasta, pet food, and more. With advanced technology and customized options, our equipment ensures consistent production quality and efficiency. Ideal for commercial and industrial food production lines, our machines are durable, energy-efficient, and easy to maintain. Whether you’re a small-scale business or a large food manufacturer, our food processing machinery can be tailored to your specific production needs.

What is Food Processing Equipment?

Food processing equipment refers to a broad range of machinery used in the food industry to transform raw ingredients into finished food products. These machines handle various processes such as mixing, cooking, extruding, drying, and packaging to enhance food quality, consistency, and safety.

In the context of food extruders, which are widely used in modern food production lines, food processing equipment includes:

Extruders – The core machine in food production lines, used to process raw materials into various shapes and textures through heat, pressure, and mechanical shear.

Mixers & Blenders – Ensure uniform mixing of ingredients before extrusion.

Dryers & Ovens – Remove moisture from the final product to extend shelf life.

Cutting & Shaping Machines – Shape products like pasta, pet food, or breakfast cereals.

Cooling & Packaging Systems – Ensure food products are properly stored and packed for distribution.

Our food processing equipment includes Fish Feed Production Line, Pet Food Production Line, Pasta Macaroni Production Line, and more, designed to meet industrial-scale production needs while ensuring efficiency and quality.

FAQ

What Are the Equipment Used in Food Processing?

Food processing involves a variety of specialized machinery designed to transform raw ingredients into finished food products. Depending on the type of food being produced, different equipment is used. Below are some essential food processing machines, particularly relevant to food extruders and related production lines:

1. Extrusion Equipment

Single-Screw Extruder – Used for simple food production processes like pasta and some snacks.

Twin-Screw Extruder – Offers better control over texture, shape, and ingredient mixing, ideal for pet food, fish feed, breakfast cereals, and textured proteins.

2. Mixing & Blending Machines

Ribbon Blender – Ensures even mixing of powders or granules before extrusion.

Dough Mixer – Used in pasta production lines to create a uniform dough.

3. Drying & Baking Equipment

Continuous Belt Dryer – Reduces moisture content in products like puffed snacks and pet food.

Hot Air Circulation Oven – Ensures uniform drying for longer shelf life.

4. Cutting & Shaping Machines

Pellet Cutter – Shapes extruded fish feed and pet food into uniform sizes.

Rotary Cutter – Used for shaping pasta, macaroni, or snack foods.

5. Coating & Flavoring Equipment

Oil Sprayer & Seasoning Drum – Enhances the taste and appearance of snacks and cereals.

6. Cooling & Packaging Machines

Cooling Conveyor – Cools extruded food before packaging.

Automatic Packaging Machine – Ensures proper sealing and labeling for distribution.

Optimized Food Processing with Food Extruders

Our food processing production lines are designed for efficiency, high output, and consistent product quality. Whether you need an extruder for pet food, pasta, or breakfast cereals, we provide tailored solutions for your production needs.

What Are the Equipment Used in Food Processing?

Food processing involves a variety of specialized machinery designed to transform raw ingredients into finished food products. Depending on the type of food being produced, different equipment is used. Below are some essential food processing machines, particularly relevant to food extruders and related production lines:

1. Extrusion Equipment

Single-Screw Extruder – Used for simple food production processes like pasta and some snacks.

Twin-Screw Extruder – Offers better control over texture, shape, and ingredient mixing, ideal for pet food, fish feed, breakfast cereals, and textured proteins.

2. Mixing & Blending Machines

Ribbon Blender – Ensures even mixing of powders or granules before extrusion.

Dough Mixer – Used in pasta production lines to create a uniform dough.

3. Drying & Baking Equipment

Continuous Belt Dryer – Reduces moisture content in products like puffed snacks and pet food.

Hot Air Circulation Oven – Ensures uniform drying for longer shelf life.

4. Cutting & Shaping Machines

Pellet Cutter – Shapes extruded fish feed and pet food into uniform sizes.

Rotary Cutter – Used for shaping pasta, macaroni, or snack foods.

5. Coating & Flavoring Equipment

Oil Sprayer & Seasoning Drum – Enhances the taste and appearance of snacks and cereals.

6. Cooling & Packaging Machines

Cooling Conveyor – Cools extruded food before packaging.

Automatic Packaging Machine – Ensures proper sealing and labeling for distribution.

Optimized Food Processing with Food Extruders

Our food processing production lines are designed for efficiency, high output, and consistent product quality. Whether you need an extruder for pet food, pasta, or breakfast cereals, we provide tailored solutions for your production needs.

How to Clean Food Processing Equipment

Proper cleaning of food processing equipment is essential to maintain hygiene, ensure food safety, and extend the lifespan of machinery. The cleaning method depends on the type of equipment, the food being processed, and the level of contamination.

1. General Cleaning Steps for Food Processing Equipment

Step 1: Pre-Cleaning Preparation

Turn off and unplug the equipment.

Remove detachable parts like extruder screws, cutting blades, and trays.

Scrape off food residues with a brush or scraper.

Step 2: Rinse with Water

Use warm water (not too hot to avoid protein buildup) to remove loose particles.

High-pressure water may be used for large industrial food processing machines.

Step 3: Apply Cleaning Solution

Use food-grade detergents or alkaline-based cleaners to break down grease and protein buildup.

For extruders, special cleaning solutions may be needed to remove starch, protein, and oil residues.

Let the detergent sit for a few minutes to loosen stubborn deposits.

Step 4: Scrub & Clean Components

Use soft brushes or non-abrasive scrubbers for sensitive parts.

For food extruders, clean the screw and barrel thoroughly to remove stuck residues.

Soak small components in the cleaning solution for deep cleaning.

Step 5: Rinse Thoroughly

Use clean water to remove detergent and debris.

Ensure all soap and chemicals are completely washed off to prevent contamination.

Step 6: Sanitize & Disinfect

Apply a food-safe sanitizer to eliminate bacteria and pathogens.

Use heat sterilization (hot water or steam) for high-risk equipment like pet food and fish feed extruders.

Step 7: Dry & Reassemble

Let all parts air-dry or use a clean cloth to wipe them.

Ensure no moisture remains to prevent mold or rust.

Reassemble the equipment and conduct a dry run to ensure proper functioning.

2. Special Cleaning Considerations for Food Extruders

For high-protein products (e.g., pet food, fish feed): Use enzymatic cleaners to break down protein residues.

For starchy products (e.g., pasta, cereal): Use warm water to dissolve sticky starch buildup.

For oily products (e.g., puffed snacks): Use degreasers to remove fat and oil deposits.

Maintain Hygiene & Efficiency with Proper Cleaning

Regular cleaning of food extruders and processing equipment ensures compliance with food safety standards, prevents cross-contamination, and improves machine performance.

Looking for high-quality, easy-to-clean food extruders? Contact us for customized food processing solutions!

Is Equipment Used to Process Food Tax-Exempt?

The tax status of food processing equipment depends on the country, state, and specific tax laws applicable to manufacturing and agricultural equipment. In many cases, food processing machinery may qualify for sales tax exemptions or reduced tax rates, but this varies by location.

1. Tax Exemptions in the U.S.

Many U.S. states provide sales tax exemptions on manufacturing equipment, including food extruders and processing machinery, if they are directly used in production.

Some states offer exemptions specifically for agricultural or food processing equipment used to produce food for human consumption.

If the equipment is used for retail or non-production purposes, it may not qualify for tax exemption.

Examples of Possible Exemptions:

Machinery used directly in food manufacturing or production.

Equipment that becomes a component of the final product.

Energy-efficient or pollution-control equipment may qualify for additional tax incentives.

Not Exempt (in some states):

Equipment used for storage, packaging, or distribution.

Machinery used for office, administration, or general business operations.

2. Tax Exemptions in Other Countries

European Union (EU): Some countries offer VAT (Value Added Tax) exemptions or reductions for industrial food processing equipment.

Canada: Certain provinces exempt food processing equipment from provincial sales tax (PST) if used for manufacturing.

Australia: Some food production machinery may qualify for GST-free (Goods and Services Tax) status under specific conditions.

3. How to Check If Your Food Processing Equipment Is Tax-Exempt

Consult your local tax authority or a tax professional.

Check for manufacturing tax exemption certificates in your country or state.

If exporting, verify if the destination country offers import duty exemptions for food production equipment.

What Oil Is Used to Lubricate Food Processing Equipment?

Lubricating food processing equipment requires food-grade lubricants that ensure safety, prevent contamination, and maintain machinery performance. The most commonly used oils for food extruders and other food machinery fall under NSF H1-certified lubricants, which are safe for incidental food contact.

1. Types of Food-Grade Lubricants

✅ Synthetic Food-Grade Oils (Best for high-performance machines)

Polyalphaolefin (PAO) synthetic oils – excellent for high-temperature and high-load applications, such as food extruders.

Ester-based synthetic oils – offer superior oxidation stability and durability.

✅ Mineral-Based Food-Grade Oils (For general use)

White mineral oil – commonly used in light-duty food machinery lubrication.

Paraffinic oil – stable under different temperatures but less durable than synthetics.

✅ Specialty Food-Grade Lubricants

H1 Hydraulic Oils – For extruder motors and hydraulic systems.

H1 Gear Oils – Used in food extruder gearboxes to handle heavy loads.

H1 Greases – Applied to bearings and moving parts exposed to moisture and food particles.

2. Key Properties of Food-Grade Lubricants

Non-toxic & FDA-compliant – Safe for incidental food contact.

High-temperature resistance – Ideal for food extruders that operate under extreme heat.

Anti-wear & corrosion protection – Extends the lifespan of food processing machinery.

Water-resistant – Prevents washing out in humid food production environments.

3. Recommended Brands for Food Processing Equipment

Mobil SHC Cibus Series – Synthetic lubricants for high-temperature and high-load applications.

Shell Cassida Series – NSF H1-approved food-grade lubricants.

Klüber Lubrication – Specialized lubricants for food and pharmaceutical processing.

NSF H1 Hydraulic & Gear Oils – For industrial food production machinery.

Choosing the Right Lubricant for Food Extruders

For food extruders and high-load processing equipment, synthetic NSF H1 oils are recommended due to their superior heat resistance and durability. Regular maintenance and the correct choice of lubricant can improve efficiency, hygiene, and machine lifespan.

Why Is Copper Not Recommended for Most Food Processing Equipment?

Copper is generally not recommended for food processing equipment due to several factors that impact food safety, durability, and compliance with food industry regulations. While copper has some benefits, such as antimicrobial properties, its disadvantages make it unsuitable for most modern food processing machinery.

1. Reactivity with Food

Copper reacts with acidic and alkaline foods, leading to metal leaching into the food.

This can cause contamination and metallic taste in processed food.

The reaction may also lead to toxic compounds, such as copper salts, which are harmful in high concentrations.

2. Corrosion & Wear Issues

Copper is highly prone to corrosion, especially in wet or high-temperature food processing environments.

Continuous exposure to moisture, heat, and cleaning chemicals causes copper to degrade over time.

Corroded copper surfaces harbor bacteria and compromise food safety.

3. Regulatory & Safety Concerns

Many food safety agencies (FDA, EU, NSF) discourage the use of copper for direct food contact surfaces.

Regulations require food processing equipment to use materials that are non-reactive, corrosion-resistant, and easy to clean.

4. Alternative Materials for Food Processing Equipment

For food extruders and industrial food machinery, better alternatives include:

✅ Stainless Steel (304 & 316 Grades) – Corrosion-resistant, durable, and food-safe.

✅ Food-Grade Plastics (PTFE, UHMWPE) – Non-reactive and lightweight.

✅ Aluminum (Anodized) – Less reactive than copper and more resistant to corrosion.

Conclusion

Copper is avoided in most food processing equipment due to its reactivity, corrosion risk, and safety concerns. Instead, stainless steel is the industry standard for food extruders and food processing lines, ensuring hygiene, durability, and compliance with food safety regulations.

Looking for high-quality stainless steel food extruders? Contact us today for custom food processing solutions!