Opening a small pet food factory requires a careful balance between ambition and realism. Budgets can range from lean entry models to fully automated lines, depending on production capacity, recipe design, compliance requirements, and location costs.

Short Answer: From $12,000 for outsourced models to $600,000 for a fully functional small factory. Key drivers include facility renovation, extrusion/drying equipment, compliance, and raw material strategy.

Overview

Lean Entry (Outsourcing + Semi-Processing): $20,000–$50,000

Micro Dry Kibble Line (80–200 kg/h): $50,000–$220,000

Small Factory (300–1000 kg/h): $200,000–$600,000

Major Variables: facility, extrusion equipment, compliance, raw materials

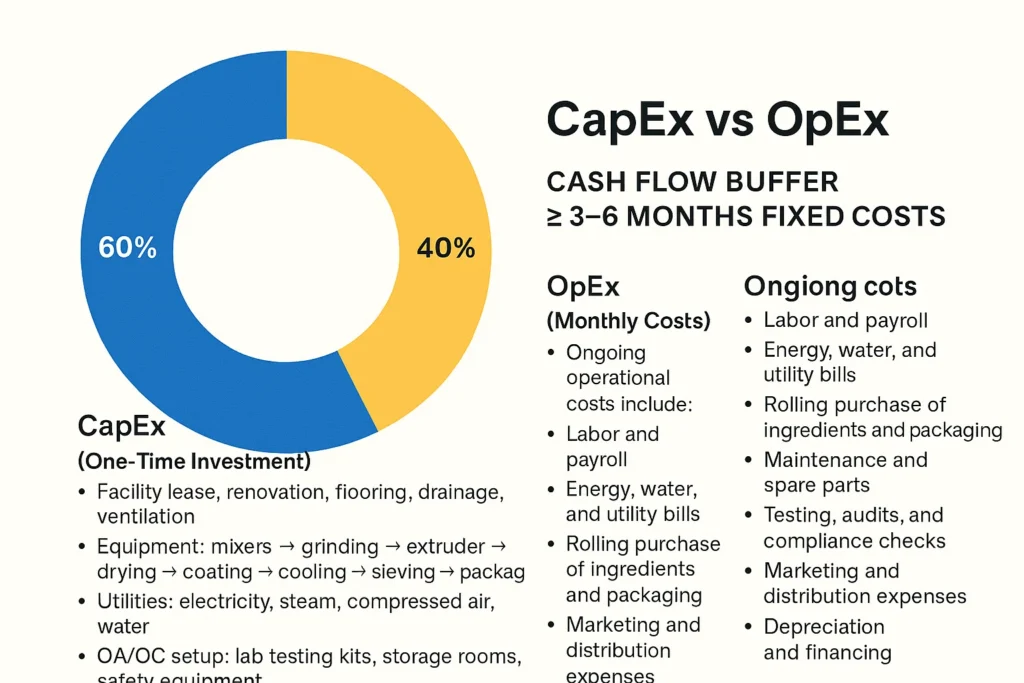

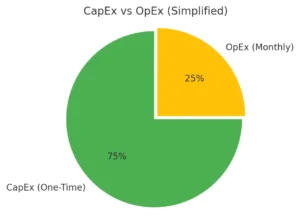

CapEx vs OpEx: Understanding Your Financial Structure

CapEx (One-Time Investment)

Major upfront costs include:

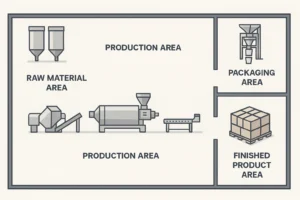

Facility lease, renovation, flooring, drainage, ventilation

Equipment: mixers → grinding → Pet Food Extruder → drying → coating → cooling → sieving → packaging

Utilities: electricity, steam, compressed air, water

QA/QC setup: lab testing kits, storage rooms, safety equipment

Initial raw materials & packaging

Registration, certification, insurance

Branding and launch materials

OpEx (Monthly Costs)

Ongoing operational costs include:

Labor and payroll

Energy, water, and utility bills

Rolling purchase of ingredients and packaging

Maintenance and spare parts

Testing, audits, and compliance checks

Marketing and distribution expenses

Depreciation and financing

Budget Scenarios & Typical Configurations

Scenario A: Lean Entry ($30k–$60k)

Focus on pre-mixing, outsourcing sterilization/packaging, renting or buying second-hand machines. Best for market validation and early DTC e-commerce.

Scenario B: Micro Dry Line ($80k–$250k)

80–200 kg/h capacity. Single-screw extrusion, belt dryer, light spraying system, semi-automatic packaging. Risks: limited recipe flexibility, moisture consistency challenges, higher variance in quality.

Scenario C: Small Standard Line ($250k–$800k)

300–1000 kg/h capacity. Optional twin-screw extruder, multi-stage drying, inline weighing and metal detection, auto-bagging and palletizing. Benefits: stronger stability, compliance readiness, scalable operations.

Wet & Semi-Moist Foods

Requires retort or aseptic filling, higher investment. Budget should anticipate $300k+ for sterilization and canning/retort systems.

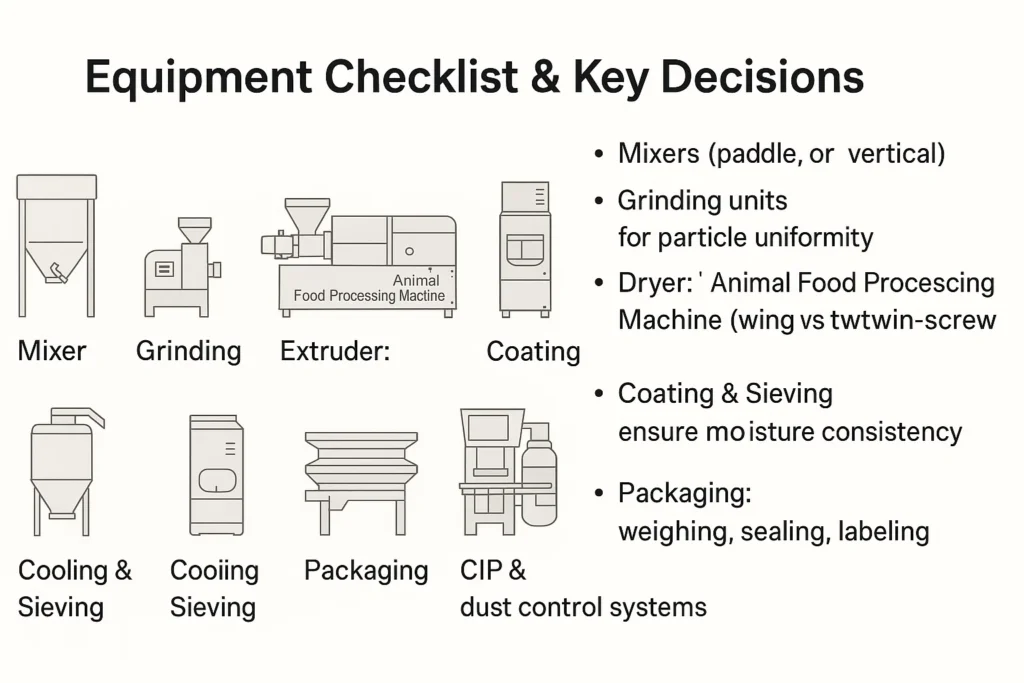

Equipment Checklist & Key Decisions

Mixers (paddle, ribbon, or vertical)

Grinding units for particle uniformity

Extruder: single vs twin-screw (Animal Food Processing Machine)

Dryer: batch vs continuous, multi-stage airflow

Coating: vacuum spraying vs atmospheric

Cooling & Sieving: ensure moisture consistency

Packaging: weighing, sealing, labeling, traceability

CIP & dust control systems

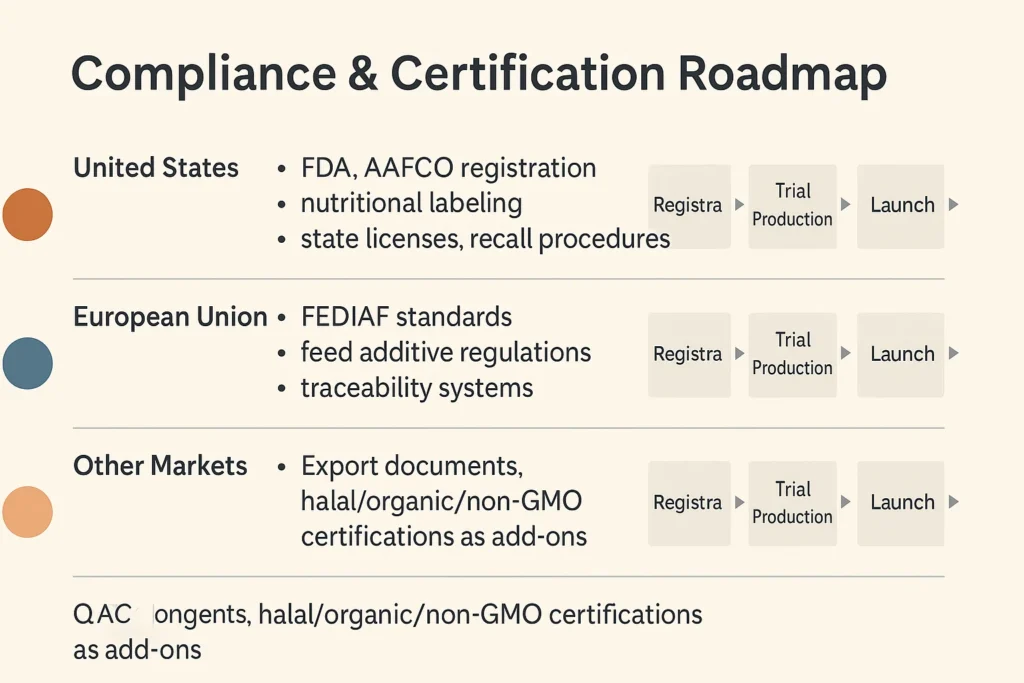

Compliance & Certification Roadmap

United States

FDA, AAFCO registration, nutritional labeling, state licenses, recall procedures.

European Union

FEDIAF standards, feed additive regulations, traceability systems.

Other Markets

Export documents, halal/organic/non-GMO certifications as add-ons.

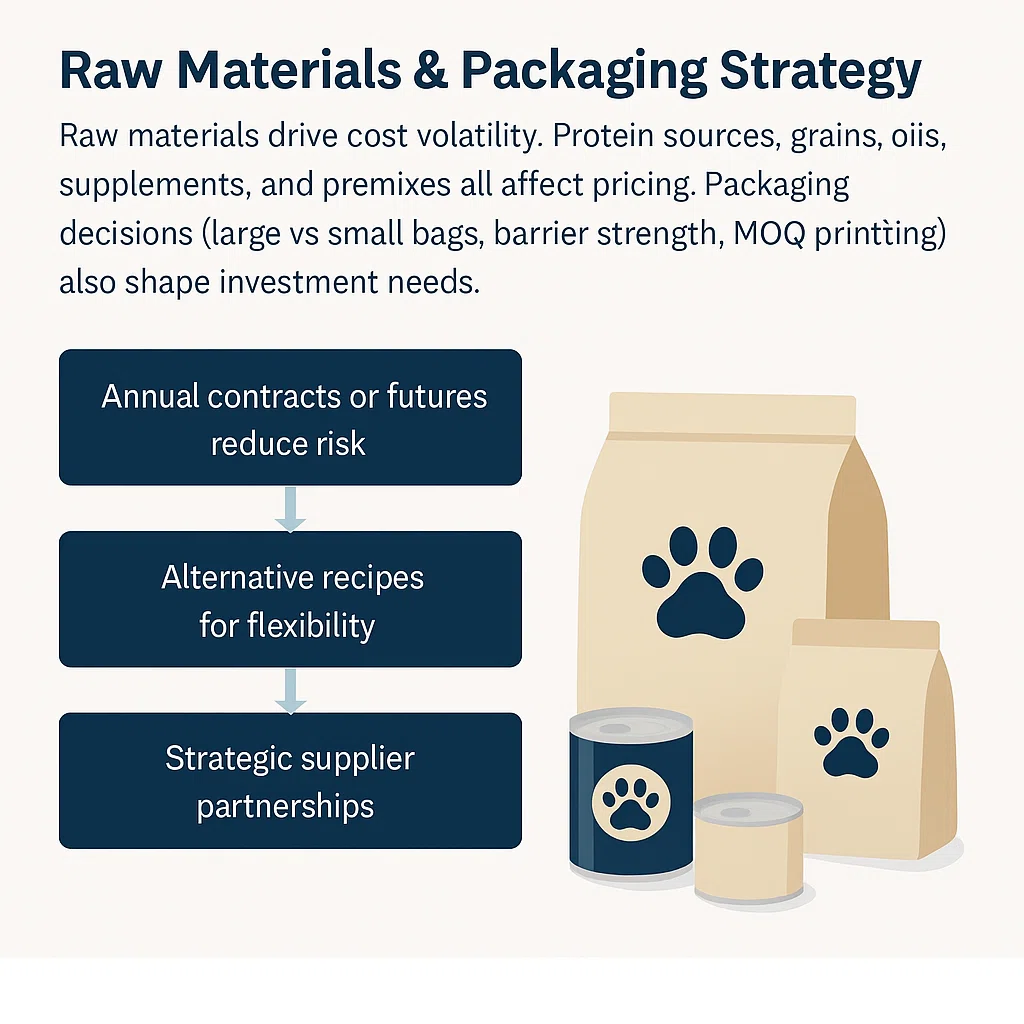

Raw Materials & Packaging Strategy

Raw materials drive cost volatility. Protein sources, grains, oils, supplements, and premixes all affect pricing. Packaging decisions (large vs small bags, barrier strength, MOQ printing) also shape investment needs.

Annual contracts or futures reduce risk

Alternative recipes for flexibility

Strategic supplier partnerships

Team & Organization: The Minimum Viable Staff

Production operators

Equipment maintenance

QA/QC staff

Procurement & warehouse

EHS and compliance

Marketing & sales

Most small plants start with one shift. Moving to two shifts doubles output but adds ~40% cost overhead (due to efficiency gains).

Practical Q&A

Is $50k enough?

Only if you outsource key stages. A micro line usually needs $80k–$100k minimum.

New vs Used Equipment?

New = higher reliability, better compliance. Used = lower cost but must be carefully inspected.

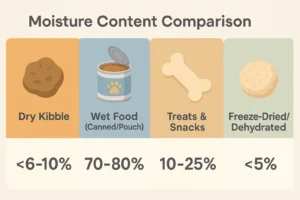

Dry vs Wet vs Freeze-Dried?

Dry kibble is cheapest to start. Wet and freeze-dried need higher budgets and stricter compliance.

Hybrid Model?

Yes, combine outsourcing with a micro line to scale quickly while keeping profit margins.

How do I calculate cost per kg?

Formula: (Fixed Costs + Variable Costs) ÷ Output. Example: $20,000 ÷ 50,000 kg = $0.40/kg.

Can automation upgrades pay off fast?

Yes, adding auto-packaging or palletizing typically pays back in 6–12 months.

Best low-cost market strategies?

Direct-to-consumer, local distributors, and ODM partnerships are cost-effective entry routes.

Templates & Tools

CapEx/OpEx budget template with scenario placeholders

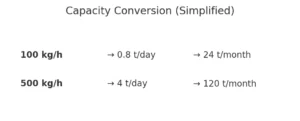

Production capacity conversion table (kg/h → tons/day → tons/month)

Compliance timeline sample chart

👉 Reach out to us for a free full template

Next Step: Match your budget to one of the three scenarios and request our free budget & capacity template.

At Zhuoheng Extrusion, we design customized Pet Food Processing Equipment that grows with your business.