What is a food extruder machine and Its Functions

A food extruder machine is a highly versatile and efficient machine used in the production of various food products. It functions as a short bioreactor, allowing the continuous transformation of raw ingredients into a wide range of final products through a single manufacturing process. This process involves mixing, cooking, and shaping ingredients under controlled conditions, including temperature, pressure, and moisture. One of the main advantages of food extrusion is its ability to process food in one step, making it cost-effective and efficient.

Food extruder machineis used in the production of various food lines, such as Fish Feed Production Lines, Pet Food Production Lines, Pasta Macaroni Production Lines, Sandwich Rice Cracker Food Production Lines, Breakfast Cereal Corn Flakes Production Lines, Puffed Food Production Lines, Fried Snack Food Production Lines, Textured Protein Production Lines, Nutritional Powder Production Lines, Modified Starch Production Lines, Bread Crumbs Production Lines, and even 2D and 3D Blank Secondary Puffing Production Lines.

Extrusion technology also offers the ability to enhance the nutritional profile of the products, allowing the addition of vitamins, minerals, and other functional ingredients. This process is an integral part of modern food production, delivering high-quality products in a quick, reliable, and efficient manner.

Other Searches

FAQ

What Is a Food Extruder?

A food extruder is a specialized machine used in food processing to mix, cook, and shape raw ingredients into a final product through a continuous extrusion process. It applies heat, pressure, and mechanical shear to transform food materials into specific shapes and textures.

How Does a Food Extruder Work?

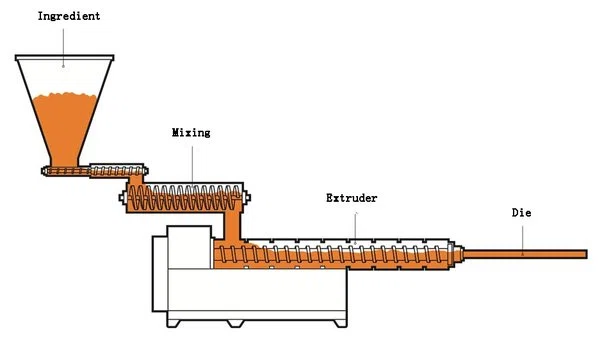

Raw Ingredients Input – Ingredients such as grains, starches, proteins, and additives are fed into the extruder.

Mixing & Heating – Inside the extruder barrel, rotating screws mix, compress, and heat the ingredients.

Shearing & Cooking – High pressure and friction further cook and modify the texture of the food.

Shaping & Cutting – The cooked mixture is forced through a die, shaping the final product (e.g., pellets, flakes, or textured pieces).

Cooling & Drying – The extruded product is cooled and dried to the desired moisture content.

Types of Food Extruders

Single-Screw Extruder – Suitable for simple processes like pasta and snack foods.

Twin-Screw Extruder – Offers better control over texture and mixing, ideal for pet food, fish feed, breakfast cereals, and textured vegetable protein.

Applications of Food Extruders

Pet & Aquatic Feed – Produces dry pet food, fish feed, and floating or sinking aquatic feed.

Snack Foods – Puffed snacks, fried snacks, and breakfast cereals.

Pasta & Macaroni – Shapes dough into pasta products.

Textured Protein Products – Used in plant-based meat substitutes.

Modified Starch & Nutritional Powder – Creates functional food ingredients.

How does a twin screw food extruder work?

A twin-screw food extruder is an advanced food processing machine that uses two intermeshing screws to mix, cook, and shape raw ingredients into a final product. It provides better control over processing parameters, making it ideal for producing a wide range of food products such as pet food, fish feed, breakfast cereals, puffed snacks, and textured vegetable proteins (TVP).

Working Principle of a Twin-Screw Food Extruder

1. Ingredient Feeding & Pre-Mixing

Raw materials (flour, starch, proteins, oils, etc.) are fed into the hopper.

An automatic feeder ensures a consistent and controlled input of materials.

2. Mixing & Conveying

Two co-rotating screws inside a barrel transport and mix the ingredients.

The intermeshing screws provide intensive shearing and kneading, ensuring uniform mixing.

3. Cooking & Moisture Control

Friction, mechanical shear, and external heating elements heat the ingredients.

The temperature, pressure, and moisture content are precisely controlled to cook the food while preserving its nutritional value.

4. High-Pressure Extrusion & Texturization

The food mass is compressed and moves forward under high pressure.

The twin-screw design allows better control over density, expansion, and texture formation.

5. Shaping & Cutting

The cooked mixture is forced through a die, shaping it into different forms (pellets, flakes, curls, or textured pieces).

A rotary cutter or blade slices the extruded material to the desired length.

6. Drying & Cooling

The extruded food product is transferred to a dryer to remove excess moisture.

Cooling conveyors reduce the temperature before packaging.

Advantages of Twin-Screw Food Extruders

Better Mixing & Ingredient Flexibility – Handles a wide range of raw materials, including high-fat and high-moisture ingredients.

Higher Processing Efficiency – Faster throughput and continuous operation.

More Precise Control – Adjusts temperature, pressure, and texture for different food applications.

Versatile Applications – Suitable for pet food, fish feed, breakfast cereals, snacks, and textured proteins.

Improved Nutritional Retention – Optimized cooking process preserves protein, vitamins, and minerals.

Applications of Twin-Screw Food Extruders

Pet Food & Fish Feed – Produces dry pet food and floating/sinking fish feed.

Snack Foods & Breakfast Cereals – Creates puffed snacks, cornflakes, and cereal products.

Pasta & Macaroni – Shapes pasta with uniform texture.

Textured Vegetable Protein (TVP) – Produces plant-based meat alternatives.

Modified Starch & Nutritional Powder – Used for baby food and industrial applications.