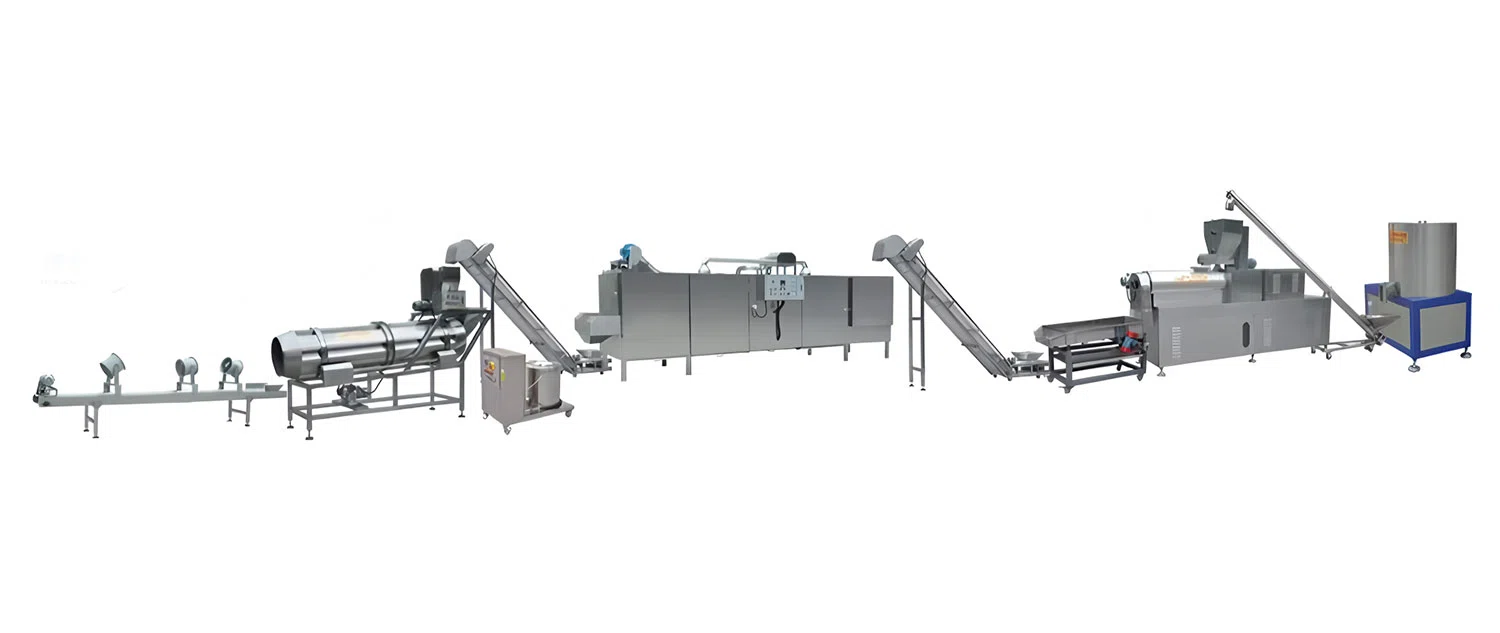

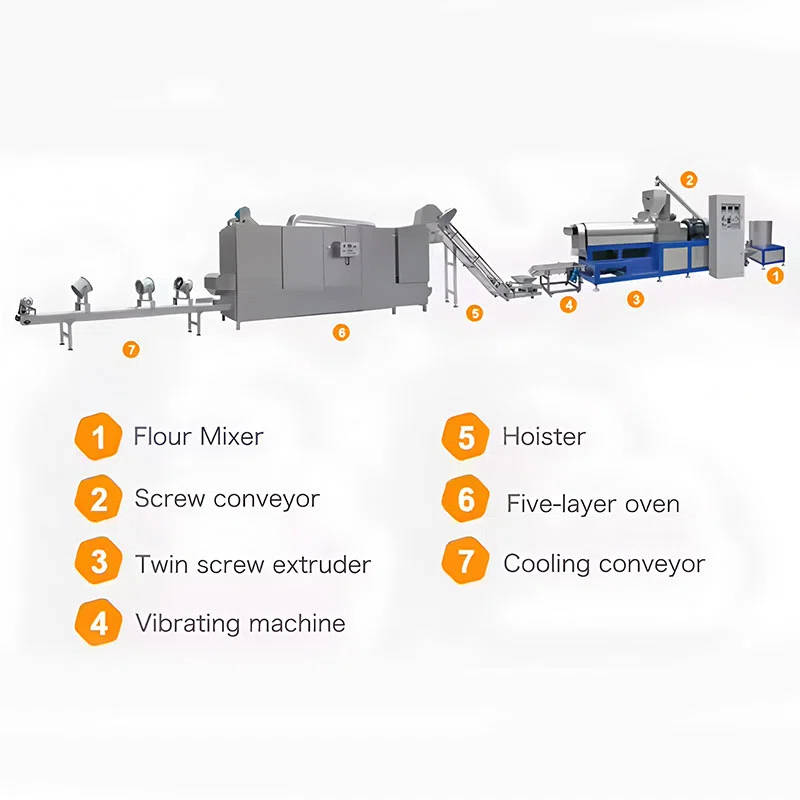

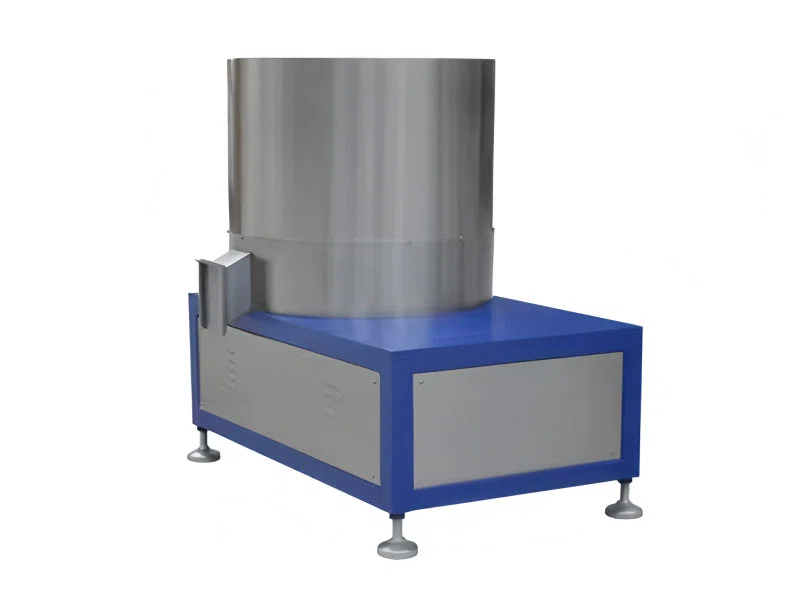

1-Extursion floating and sinking fish feed, pet food ,

2-Pasta macaroni,

3-leisure snacks food ,

4-breakfast cereal food and corn flakes,

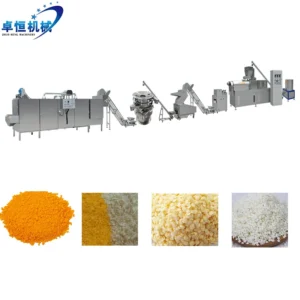

5-fried flour food, bread crumb,

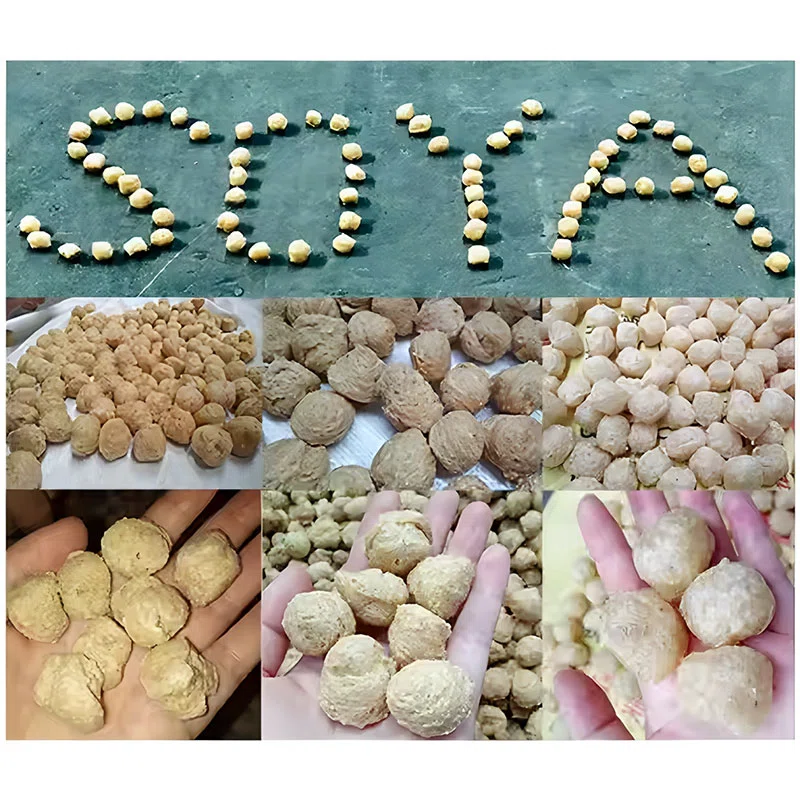

6-textured soya protein and vegetarian meat, etc.

More than twenty production line can be chosen. And we can also provide customized service for special requirements.(offer OEM & ODM services)