Pasta Macaroni Production Line

Our Pasta Macaroni Production Line utilizes vacuum cold extrusion technology to ensure thorough mixing of flour and water, allowing for optimal dough maturation through screw extrusion. This advanced process enhances the quality of pasta, making it easier to produce traditional Italian-style pasta.If you have a need for custom industrial food processing equipment, please check out all of our food processing machines.

Video display

Exhibition video

Key Features & Benefits

Advanced Vacuum Extrusion Technology – Ensures full combination of flour and water for high-quality pasta production.

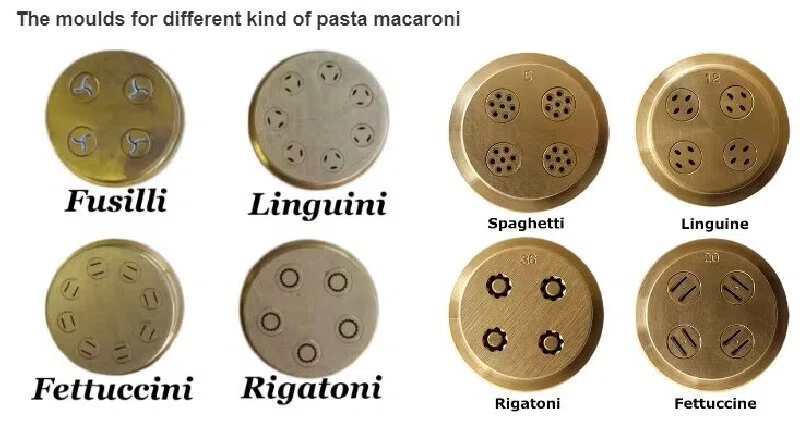

Versatile Production Capabilities – Able to produce various pasta shapes, including : tube,elbow,screw,shell,and more.

High Efficiency & Automation – The production line includes Extruder unit-pre dryer-oven-cooling-packing to optimize each phase of pasta making.

Imported Molds from Italy – Ensures precision shaping and high-quality pasta texture.

Robust & Stable Performance – The machine completes ripening, extruding, and shaping in a single step without requiring a boiler.

Excellent Cooking Resistance – The pasta retains its shape and texture even after boiling for 45 minutes.

Production Capacities

200kg/h Pasta Machine Extruder

100kg/h Pasta Extruder

Raw Materials

The Pasta Macaroni Making Machine primarily uses 100% semilina flour and water, with the option to add other nutritional ingredients for enhanced product variety and quality. With cutting-edge Italian pasta technology and a well-engineered design, our Industrial Pasta Macaroni Production Line delivers smooth, glossy, and delicious pasta that meets the highest market standards.

Detailed Description

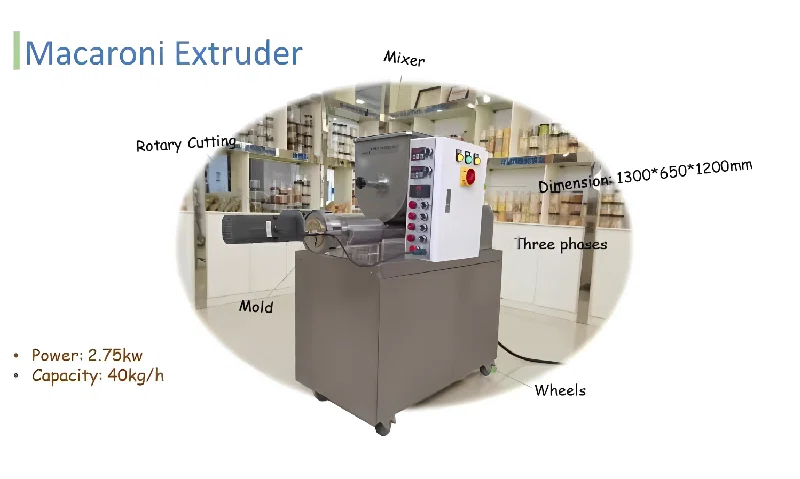

Model | Installed power | Power consumption | Capacity | Dimension |

ZHK | 2.75 kw | 2.75 kw | 30-40 kg/h | 1300*650*1200mm |

TXF-100 | 8.85 kw | 5.5 kw | 100 kg/h | 2200*800*1800mm |

TXF-200 | 31 kw | 19 kw | 200 kg/h | 3900*2750*4500mm |

TXF-300 | 45 kw | 35 kw | 300 kg/h | 4500*3500*4500mm |

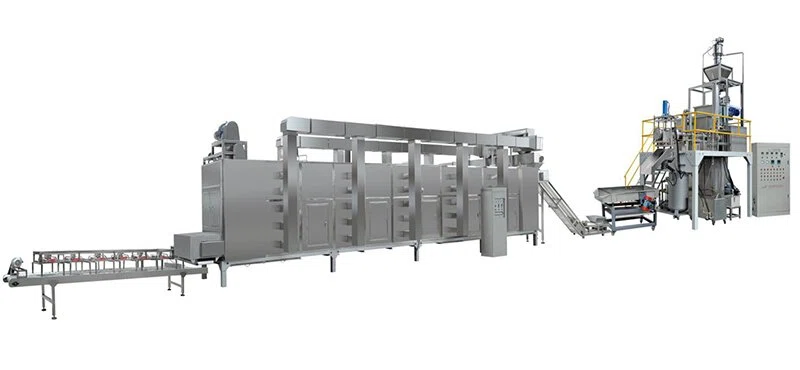

This is our 200kg/h pasta machine extruder . Our Industrial Price Pasta Macaroni Making Machines is designed according to the specific plant requirements to optimize all

phases of production of fresh pasta and includes automatic mixers, extruders, sheeters, moulders, pasteurizers, dryers and

coolers.

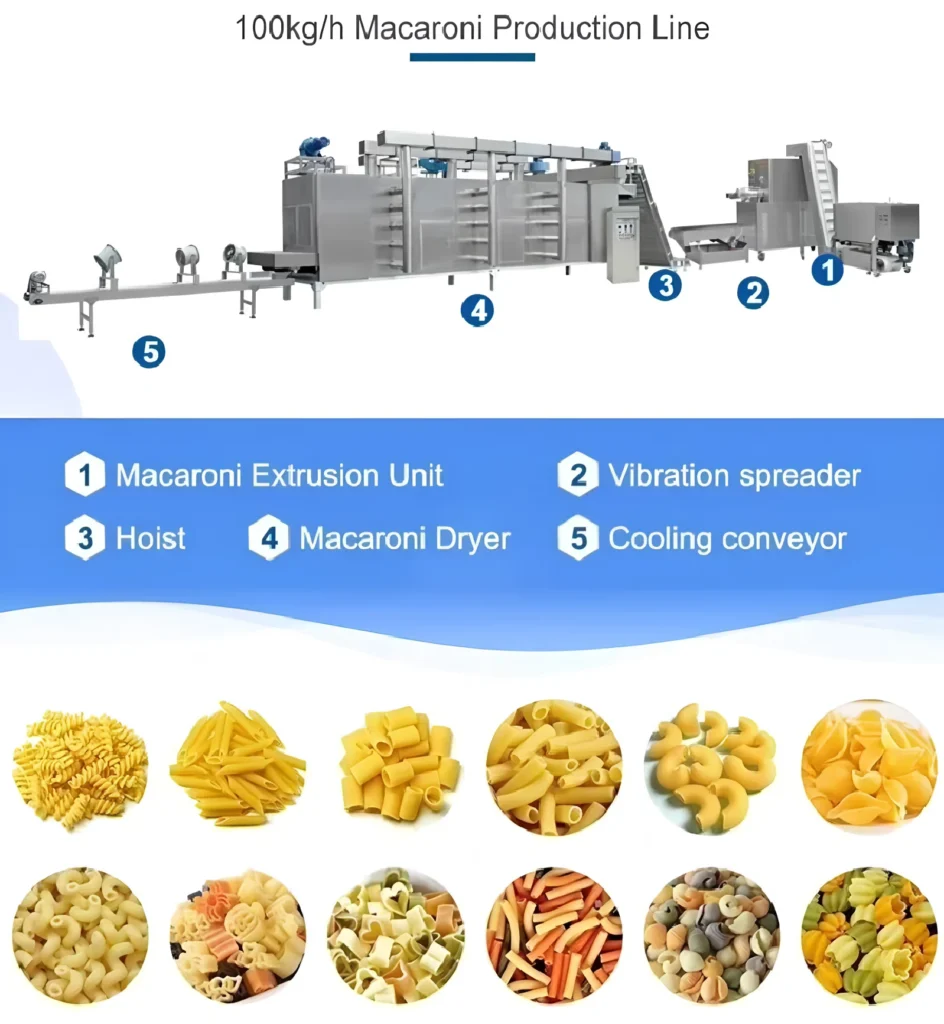

100kg/h pasta extruder Raw Material : Industrial Price Pasta Macaroni Making Machines adopts only flour and water as raw materials. Also can add other

nutritional materials.

Macaroni extrusion unit

Extrusion Forming Unit is consist of Mixer,

Conveyor and Pasta Extruder.

Capacity: 80-100kg/h

Dimension:1600*2000*1800

Power: 12.5kw

Pre-dryer

Function: avoid products stick together.

Capacity: 100-150kg/h

Dimension:2200*720*1200

Power:7.85kw

Macaroni dryer

Hot air drying, large capacity; High efficiency and energy saving, especially suitable for

drying raw materials that have large moisture, the effect is very obvious.

| Item | Material & Brand |

|---|---|

| Screws Material | 38CrMoAl Alloy Steel by Nitriding |

| Screws Process | High Strength and Wear-Resistance |

| Body Material | Food Grade Stainless Steel (201, 304, 316 as required) |

| Main Motor | Siemens (China) |

| Inverter | Pioneer, Delta, ABB, etc. (As required) |

| Electric Parts | CHNT, ABB, Schneider, etc. (As required) |

| Capacity | 120kg/h – 4000kg/h |

| Power Supply | Based on 380V 50Hz 3 Phase (Customizable) |

| Certificate | CE, GOST, SGS, BV |

| Raw Material | Corn Meal, Flour, Soy Meal, Peanut Meal, Bone/Meat/Fish/Shrimp Powder, etc. |

| Product Type | Dog Food, Cat Food, Fish Feed, Bird Food |

| Product Shape | Pellet, Ball, etc. (Customizable) |

| Product Size | Diameter: 1mm to 10mm |

Drawing 160-220kg/h Pasta Macaroni Processing Line

Mian advantage

1.The pasta macaroni making machinery adotps most advanced technology in the word Making water and flour more fully mixed together to produce a variety productions in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave etc.

Contact us Now

Request detailed information

The Strength Behind Our Factory Team

Our factory is equipped with advanced production equipment and rich technical experience. The strong reputation of our brand is built on the collective efforts of every team member. With an experienced technical team and a well-established management process, we strictly adhere to quality management standards to ensure that every product meets international quality requirements. We are committed to providing our customers with stable, reliable, and high-quality products, always upholding excellent service to meet the needs of every client.

Our Company

1-Extursion floating and sinking fish feed, pet food ,

2-Pasta macaroni,

3-leisure snacks food ,

4-breakfast cereal food and corn flakes,

5-fried flour food, bread crumb,

6-textured soya protein and vegetarian meat, etc.

More than twenty production line can be chosen. And we can also provide customized service for special requirements.(offer OEM & ODM services)

Customer Feedback

What can we do?

Our Certificates

FIRST-CLASS SERVICE AND FIRST-CLASS QUALITY

FAQ

We are a professional manufacturer of food & feed extrusion machine

You can inquiry to us directly.We will send the quotation to you as soon as possible.My Wechat/Skype/Whatsapp:+0086 15820016777

.

T/T 30% as down payment, 70% by T/T before delivery.

We can provide basic formula for produce the food etc. And help customer to produce new products according to customer’s formula.

The production line can be put in straight line and also can change the direction according to

to your factory size.

Send engineers for installation, trial running and training workers at customer’s site.Handling the problems occurred during use.

Supply spare and wearing parts on discount.Help customers to solve any other problems.