Puffed Snack Food Production Line

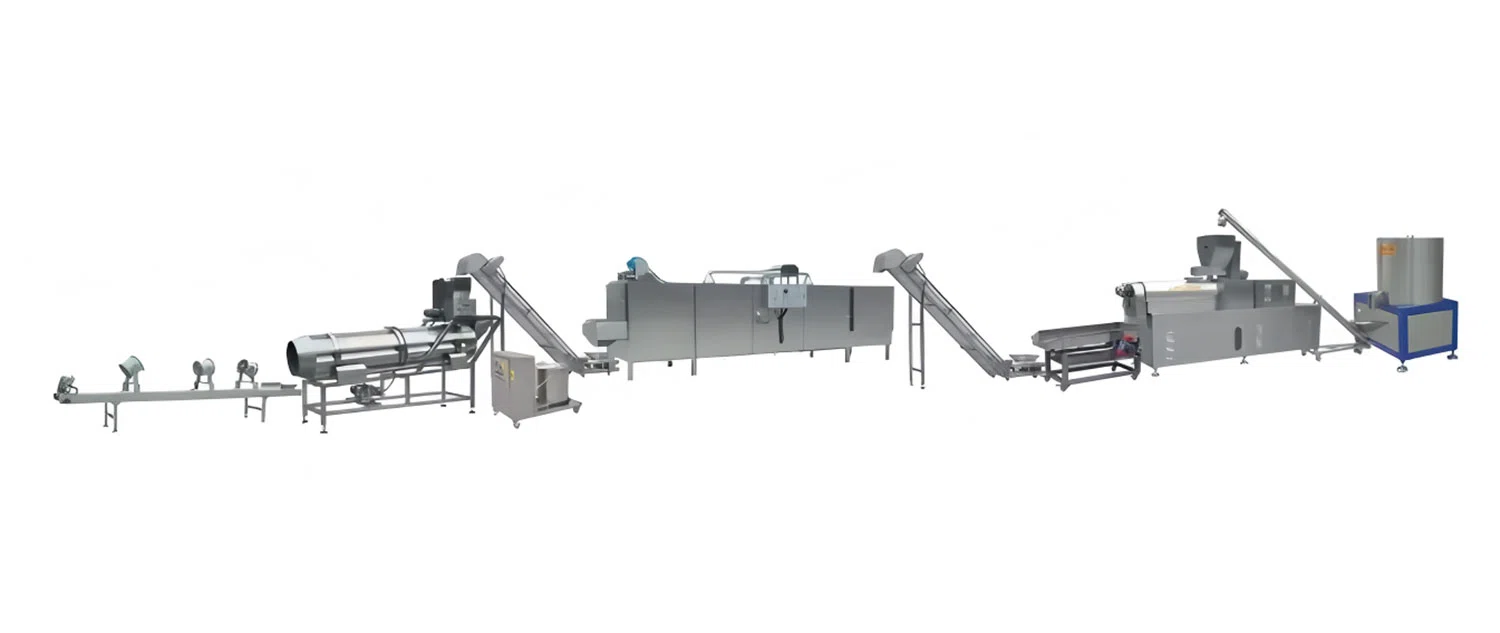

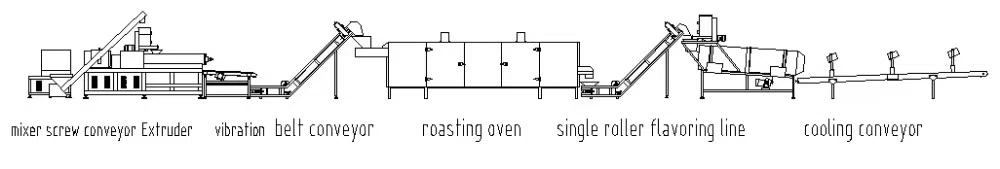

The Puffed Food Production Line is an advanced, fully automated system designed for producing high-quality puffed and core snacks using state-of-the-art extrusion technology. The process seamlessly integrates stirring, extrusion, forming, filling, cutting, drying, seasoning, and cooling, while interchangeable molds allow for a wide range of snack shapes. Constructed from durable stainless steel, this production line offers high efficiency, low power consumption, and consistent output.

If you have a need for custom industrial food processing equipment, please check out all of our food processing machines.

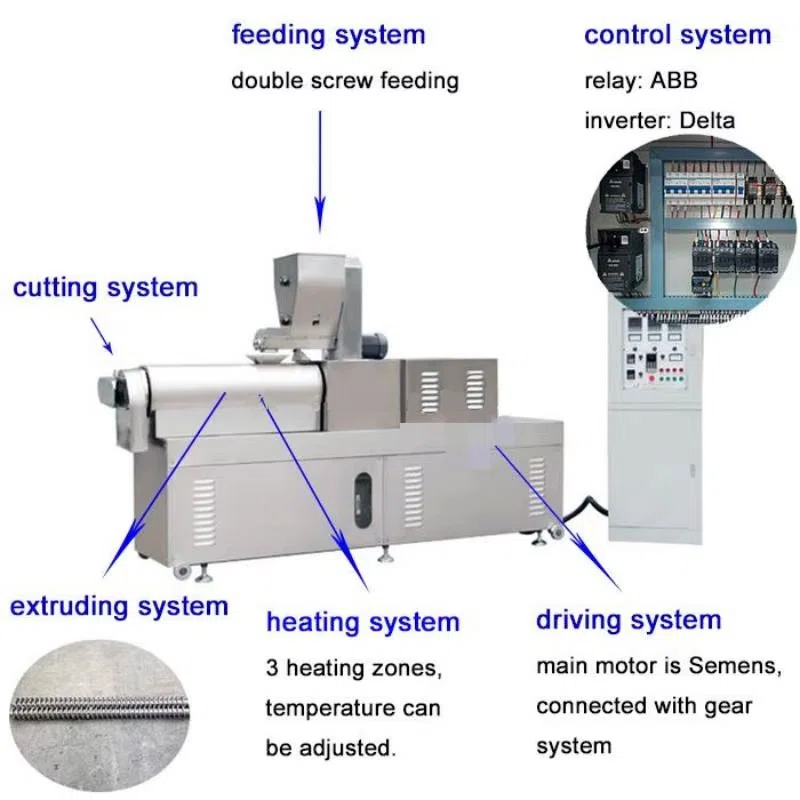

Key Features of the Snack Extruder Machine :

High-Quality Construction: Made from stainless steel, this machine is built to last, ensuring hygiene and durability in every operation.

Customizable Shapes: Equipped with different molds, it allows you to produce a variety of snack shapes to meet diverse market demands.

Double Screw Extruder: Ensures consistent and efficient puff snack production, ideal for corn flour and other raw materials.

Compact Design: With dimensions of 3000*1100*1950mm, it’s perfect for small to medium-sized factories.

Advanced Technology for Snack Production

Automatic Operation: Streamline your production process with minimal manual intervention, saving time and labor costs.

Hot Air Circulation System: Ensures even heating for perfect puffing and texture.

Multiple Power Options: Choose from electric, gas, or diesel power sources to suit your facility’s needs.

Detailed Description

1. The puffed snacks and core snacks production line adopts advanced extrusion technology, which realizes automation from stirring, extrusion, forming, filling, cutting, drying, seasoning and cooling.

2. Corn filling snacks and puffed foods of different shapes can be produced by changing the mold.

3. The automatic process has the advantages of normal materials, convenient operation and maintenance, low power consumption, high output, etc., and is at a leading level.

Type | Capacity | Main Motor Power | Dimension(m) |

ZH65 | 120~150kg/h | 22kw | 3*1.1*1.9 |

ZH70 | 200~250kg/h | 37kw | 3.3*11*2.2 |

ZH85 | 300~500kg/h | 75kw | 3.58*1.04*2.05 |

Contact us Now

Request detailed information

The Strength Behind Our Factory Team

Our factory is equipped with advanced production equipment and rich technical experience. The strong reputation of our brand is built on the collective efforts of every team member. With an experienced technical team and a well-established management process, we strictly adhere to quality management standards to ensure that every product meets international quality requirements. We are committed to providing our customers with stable, reliable, and high-quality products, always upholding excellent service to meet the needs of every client.

Our Company

1-Extursion floating and sinking fish feed, pet food ,

2-Pasta macaroni,

3-leisure snacks food ,

4-breakfast cereal food and corn flakes,

5-fried flour food, bread crumb,

6-textured soya protein and vegetarian meat, etc.

More than twenty production line can be chosen. And we can also provide customized service for special requirements.(offer OEM & ODM services)

Customer Feedback

What can we do?

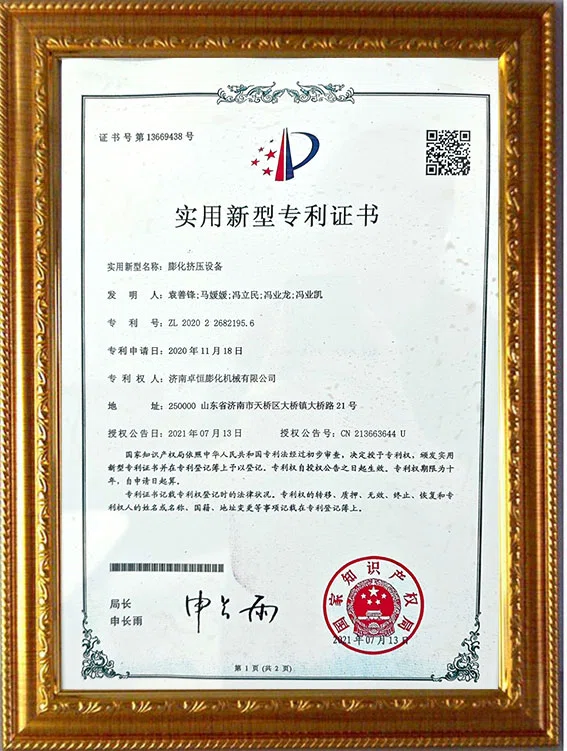

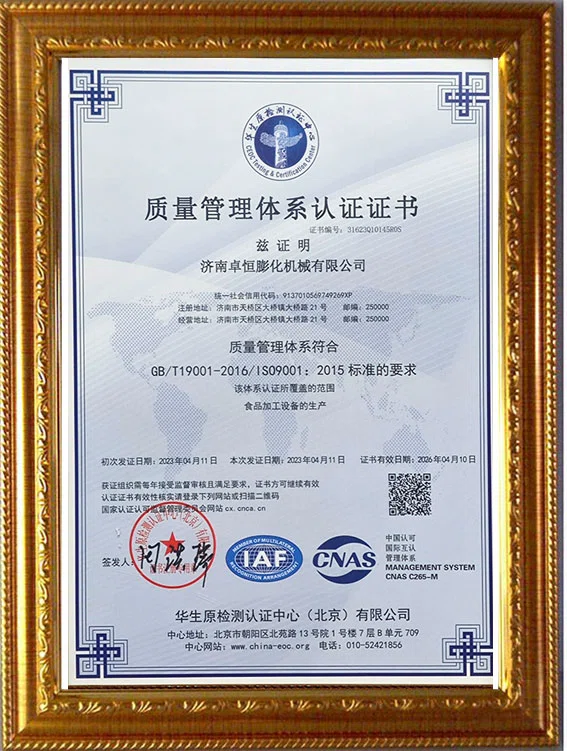

Our Certificates

FIRST-CLASS SERVICE AND FIRST-CLASS QUALITY

FAQ

We are a professional manufacturer of food & feed extrusion machine

You can inquiry to us directly.We will send the quotation to you as soon as possible.My Wechat/Skype/Whatsapp:+0086 15820016777

.

T/T 30% as down payment, 70% by T/T before delivery.

We can provide basic formula for produce the food etc. And help customer to produce new products according to customer’s formula.

The production line can be put in straight line and also can change the direction according to

to your factory size.

Send engineers for installation, trial running and training workers at customer’s site.Handling the problems occurred during use.

Supply spare and wearing parts on discount.Help customers to solve any other problems.