الإجابة في كل مكان في العالم تقريبًا هي نعم-أنت بحاجة إلى نوع من التصريح أو الترخيص أو التسجيل من أجل تصنيع وبيع أغذية الحيوانات الأليفة. ولكن يختلف نوع التصريح، والسلطة التي تصدره، والجدول الزمني للحصول عليه بشكل كبير. وبالنسبة للمصنعين الموجهين للتصدير، فإن فهم هذه الاختلافات أمر بالغ الأهمية لتجنب التأخير في الشحن أو الغرامات أو رفض البضائع.

نظرة عامة عالمية: كيف تختلف القواعد حسب المنطقة

تشترك اللوائح الخاصة بإنتاج أغذية الحيوانات الأليفة في موضوعات مشتركة - السلامة، وإمكانية التتبع، والشفافية في وضع العلامات - ولكن كل منطقة تطبقها بشكل مختلف. فيما يلي لمحة مقارنة:

| المنطقة | الهيئة الرئيسية | التصريح/المتطلبات الرئيسية | الملاحظات |

|---|---|---|---|

| الولايات المتحدة الأمريكية | هيئة الغذاء والدواء الأمريكية (CVM) + مكاتب الأعلاف الحكومية | تسجيل المنشأة، وترخيص الأعلاف، والموافقة المسبقة على التسمية | يجب أن تتبع الضوابط الوقائية في هيئة الغذاء والدواء الأمريكية؛ معايير AAFCO المرجعية على نطاق واسع |

| الاتحاد الأوروبي | إرشادات المفوضية الأوروبية (DG SANTE) + إرشادات FEDIAF | تسجيل مشغلي شركات الأعلاف، ونظام تحليل المخاطر ونقاط المراقبة الحرجة ونقاط المراقبة الحرجة وإمكانية التتبع | معايير موحدة عبر الدول الأعضاء؛ صارمة بشأن المواد المضافة والكائنات المعدلة وراثيًا |

| الصين | وزارة الزراعة والشؤون الريفية | تصريح إنتاج أغذية الحيوانات الأليفة، وإيداع الملصقات، وتسجيل الاستيراد/التصدير | يجب أن تشتمل الملصقات على اللغة الصينية؛ والموافقة على المكونات خاضعة لرقابة صارمة |

| كندا | الوكالة الكندية لفحص الأغذية (CFIA) | تسجيل الأعلاف، وامتثال المنشآت، وقواعد جنون البقر، وقواعد جنون البقر | التركيز على الموافقات على المكونات واعتماد الاستيراد |

ماذا عن التكاليف والجداول الزمنية؟

بعيدًا عن اللوائح، يسأل كل مستثمر كم من المال وكم من الوقت؟ التكاليف والجداول الزمنية تختلف، لكن النطاقات العملية هي

رسوم التسجيل: من بضع مئات من الدولارات الأمريكية (ترخيص منشأة صغيرة) إلى عدة آلاف (مصنع معتمد للتصدير)

ترقيات المرافق: $50,000-$300,000+ لتقسيم المناطق الصحية ومياه الصرف الصحي ومناولة الهواء والأرضيات المتوافقة

الإطار الزمني: 3-12 شهرًا حسب الإنشاء وقائمة انتظار الفحص ونطاق المنتج (أطول بالنسبة للأعلاف المعلبة/المعالجة)

قد تنطلق الشركات الصغيرة بشكل أسرع في إطار حالة "المنشأة المؤهلة" في الولايات المتحدة أو استثناءات "المشاريع الصغيرة" في الاتحاد الأوروبي. ولكن يجب على المصدرين على نطاق واسع أن يتوقعوا إجراء عمليات تدقيق كاملة وخطط موثقة لنظام تحليل المخاطر ونقاط المراقبة الحرجة قبل أن تغادر الشحنة الأولى الميناء.

الأخطاء الشائعة عند التقدم بطلب للحصول على تصاريح

الاستهانة بقواعد وضع العلامات: يمكن أن يؤدي فقدان الوزن الصافي بالوحدات المترية والإمبراطورية على حد سواء إلى منع الاستيراد.

تحليل المخاطر غير مكتمل: يعد تجاهل المخاطر المادية (مثل الشظايا المعدنية) فشلًا شائعًا في التدقيق.

لا يوجد تقسيم للمناطق الصحية: خلط تدفقات المنتجات الخام والمنتجات النهائية ينتهك ممارسات التصنيع الجيدة.

نسخ قواعد الغذاء البشري مباشرة: بعض الإضافات الآمنة للإنسان (مثل إكسيليتول) سامة للحيوانات الأليفة.

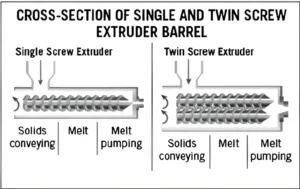

لماذا تعتبر المعدات مهمة للامتثال

لا يمكن للأعمال الورقية وحدها أن تمنحك تصريحًا. فالمنظمون ينظرون إلى ما إذا كان خط الإنتاج الخاص بك يمكنه التحكم في المخاطر باستمرار. النظافة الصحية آلة بثق أغذية الحيوانات الأليفة والأنظمة المتكاملة تجعل من السهل تنفيذ خطوات القتل، والحفاظ على التعقيم، وتوثيق الضوابط.

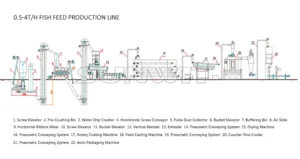

الترقية بثقة :إذا كنت تتوسع في التصدير، ففكر في حلنا الكامل: خط إنتاج أغذية الحيوانات الأليفة.

دراسة حالة إفرادية: مصدّر متوسط الحجم

خطط أحد العملاء في جنوب شرق آسيا لتصدير أغذية الكلاب الجافة إلى الشرق الأوسط. فشلت منشأتهم في الفحص بسبب تكاثف عادم المجفف بالقرب من العبوات. بعد تركيب معدات تجهيز أغذية الحيوانات الأليفةاجتازوا التدقيق في غضون 90 يومًا وحصلوا على عقود مضمونة.

الخاتمة

التصاريح ليست مجرد بيروقراطية - فهي تبني الثقة وتفتح الأسواق العالمية. سواءً كانت محلية أو للتصدير، صمم الامتثال في مصنعك في وقت مبكر. لدينا آلة تجهيز الأغذية الحيوانية تساعدك الحلول على تقليل المخاطر، وتبسيط عمليات التدقيق، وتتيح لك التركيز على النمو.

سؤال وجواب

كيف أعرف ما إذا كان بلدي يتطلب التسجيل الفيدرالي؟

ج: راجع السلطات الوطنية لسلامة الأغذية (على سبيل المثال، إدارة الغذاء والدواء، والهيئة الأوروبية لسلامة الأغذية، والهيئة الأوروبية لسلامة الأغذية، والوكالة البحرية الملكية المغربية).

ما هي أسرع طريقة للتحضير للتصدير؟

ج: التأكد من وضع العلامات ثنائية اللغة، وترميز الدفعة والتحقق من صحة المختبر. طلب إجراء عمليات تفتيش وهمية.

هل أحتاج إلى تأمين؟

ج: نعم، غالبًا ما يطلب المستوردون تأمين المسؤولية عن المنتجات.

هل يمكنني الاستعانة باستشاريين بدلاً من أخصائي تغذية بدوام كامل؟

ج: نعم. توظف العديد من الشركات استشاريين مستقلين لتلبية المعايير مثل AAFCO/FEDIAF.

ماذا لو قمت بإعداد الحلوى فقط؟

ج: لا تزال القواعد سارية. تظل قواعد السلامة ووضع العلامات والتعقيم إلزامية.